S. Vincen Bowles: Father of the Front Loader

By Eric Voytko and Zachary Geroux

With Photos from the Bowles Archive

Courtesy of Duane Bowles, and Digitized by Bill Tetreault

Samuel Vincen Bowles in 1932

Samuel Vincen Bowles was born in 1910. After putting himself through college and obtaining a mechanical engineering degree, he worked for a company called Clyde Woods building and designing heavy equipment for construction on the All American Canal in the 1930's. In 1947 he founded the S. Vincen Bowles Company in Sun Valley, California. The new firm built canal equipment, dump trucks and specialty equipment upon request. He also built, but never patented, the first champ forklift for a concrete company in the San Francisco Bay Area. He took the back end off a Model 'A' car, and made the first forklift designed to be pulled behind a trailer, and then load and unload its cargo.

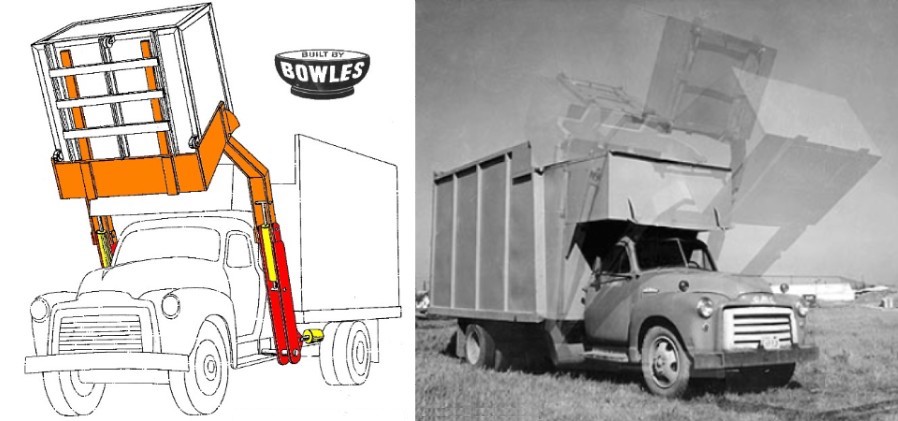

Philip Gentilie Sr. was the owner of United Rubbish Co., a Los Angeles refuse removal firm. In 1952, Gentile and Vince Bowles collaborated to design the first front loader, applying for a patent in 1953. This was a non-compacting, open-top body with a permanently fixed bucket assembly that normally rested near the front bumper of the truck. The driver (and any helpers) would hand-load refuse into the bucket, which was carried by twin pivoting arms. Once filled, it was hydraulically raised and inverted into the body to empty the contents. This method allowed for loading of a very tall, high capacity truck body without the danger and inefficiency of having workers hoist barrels over the top. It was to be only the first of many innovative trucks to emerge from Sun Valley, and the forerunner of today's modern front loading refuse trucks. From this humble beginning, the S. Vincen Bowles Company would become a major force in the southern California refuse body market, and have a profound influence on the industry as a whole.

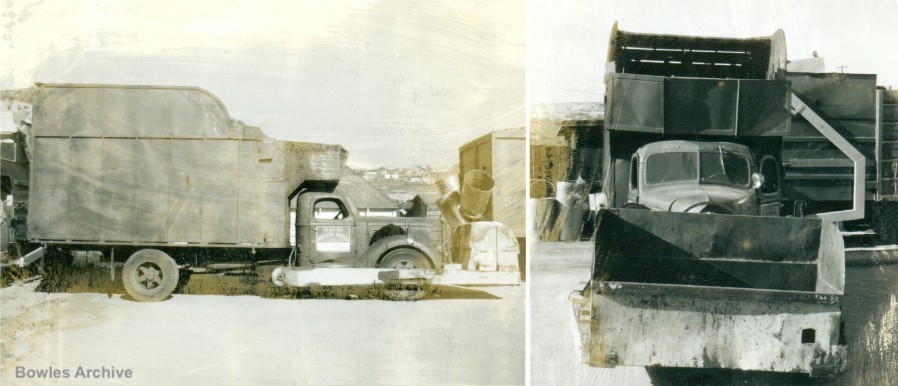

The first Bowles front loader, in service with United Rubbish Co. (1952)

The problem of commercial waste collection was not new in the 1950s, with businesses often having to dispose of waste using dozens of conventional trash barrels. The Dempster Brothers firm had already started to address the problem in the 1940's with their Dumpster portable container system. The Dempster Dumpster, although a major breakthrough in commercial collection, was basically a 'short haul' system. It required one truck be dedicated to service one container at a time, and was often not practical unless the dump was close to the collection point.

Two views of a very early Bowles front loader owned by Seaside Disposal Service

In 1954, Bowles and Gentile came up with an idea; make the bucket to their front loading truck detachable, which allowed it to be left at the pick up site. With this simple modification, a single truck could now empty multiple containers, on the spot, at sites throughout a wide service area. The bigger the truck body, the more containers could be emptied on any given collection route. A single open container, carried in the lowered position, could still be used for residential hand-loading collection routes. Yet the very same truck could still handle any commercial, detachable container stops along the way. What was happening in southern California was the genesis of a new era in bulk refuse handling, and would forever change the way commercial refuse was collected.

Gentile filed for a U.S.patent on the detachable container front loader in February of 1955, assigning a one-half interest to Bowles. The system utilized a flat fork coupling method to engage corresponding channels on the bottom of the container. Of course, there are many different ways that a front loader can engage a container to hoist it. When these machines first appeared in the 1950's, many refuse haulers wanted sliding forks because they thought of front loaders as an offshoot of the cargo-handling forklift truck. Vince strongly discouraged this. He did so because front load bodies were then typically mounted on long-nosed conventional-cab truck chassis, which severely limited the driver's visibility when hooking up with containers. Bowles pushed for a side pocket fork to give drivers more of an advantage. Nevertheless, bottom channel forks would dominate in Southern California during the early years. Many trucks were sold with adjustable forks because there was no standard width between channels, and companies would buy unique containers just to discourage other haulers from stealing their boxes. Today, the bottom channel method is still around, almost exclusively in Southern California, while side pockets are universally accepted as the standard.

A Bowles non-comp front loader with side channel forks owned by Lawndale disposal. Vince Bowles personally favored the side fork system, but popular demand was for the bottom channel type. Truck is a 1953-55 International

|

A later model Bowles non-comp with side forks from Colorado, circa 1956

Non-compacting bodies could be easily converted top-packs by with little modification. This Webster's truck

has an added packer blade (in the over-cab compartment), packer ram and body reinforcement

EXPERIMENTAL RESIDENTIAL SIDE LOADER (1956)

The round side loader shown above is probably the first Bowles side loader built, though it never entered regular production. This was an "experimental" model for Chet Ott, which was delivered in September 1956. This truck probably has a much in common with the 1930s Colecto bucket loaders, as it does with Pak-Mor, which it resembles. It has a fixed side bucket, and the packer blade appears to be guided on rails along the roof. Blade may have been operated by winch and cable, a method not uncommon on side loaders of this period.

|

1/17/10

© 2010

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

| |