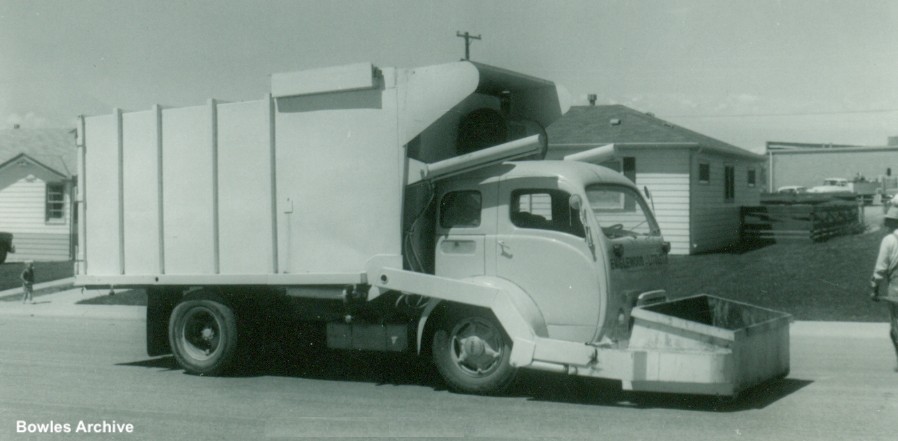

EARLY BOWLES 'PUSH-TYPE' PACKER

Although best know for their Pull Back partial packers, Bowles began building Push Type packers, partial and full-pack, very early-on as well. The oldest known example is from 1957, a fixed-bucket residential front loader with long, single-stage packer blade rams extending out of the body and over the roof of the cab. This bizarre looking truck may have been experimental, or possibly a "one off" special, custom-built for the Colorado contract hauler for Englewood-Littleton. The enclosed body brace work was similar to other Bowles packers of that era, but the lift arms and fixed front bucket were reminiscent of the earliest model from 1952. It apparently was a full-pack, with the unusually long single-stage packing rams in place of what normally would be multiple-stage telescopic cylinders.

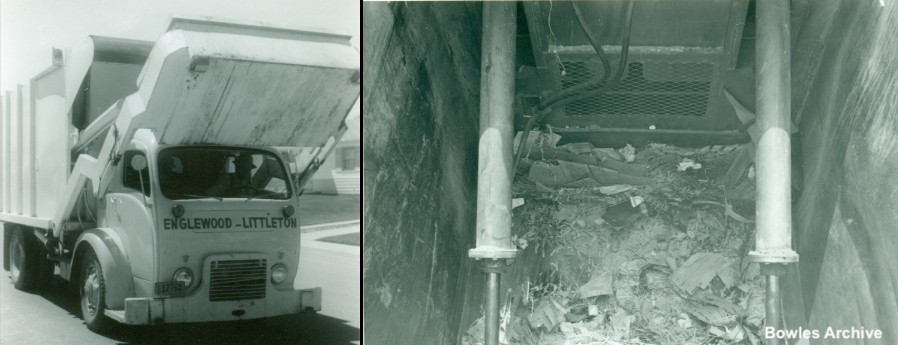

Englewood-Littleton truck attracts curious onlookers as it goes about its collection duties

Above we see the bucket being raised. At right, a view of the packing cylinders from above the hopper opening.

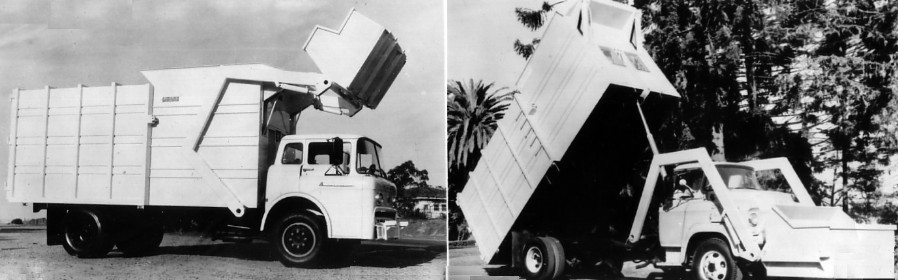

REGULAR PRODUCTION BOWLES 'PUSH-TYPE' PACKERS

By 1958-59, a far more conventional looking push-type packer was being produced, which would become a popular style with Bowles and other manufacturers. It is a partial-pack with two angle-mounted 4" packing cylinders in front of the blade. One end of each cylinder was pivotally attached to the top front end of the body. The other end was attached to the lower front frame of the packer blade. The Partial Pack versions, using single-stage cylinders, outwardly appear similar to the pull-type Bowles, except for the obvious absence of roller tracks on the sides.

Looking straight ahead, the tops of the packer cylinders can be seen above the cab

This unusual looking truck is one of two sold to the U.S. Air Force Academy in 1958. The model BF-16-FL (Full-Pack) features side forks and two 6-1/4" cylinders that operate the packer blade. These Bowles full-pack models were listed as having telescopic packing cylinders, but this short-bodied version may have been able to make use of single-stage rams instead.

Because of the unusual design of the tailgate and body (bisected at an angle), the blade does not travel the entire length of the body; it was only necessary that it reach the rear edge of the floor to unload. Any refuse trapped in the tailgate would fall out when it was hydraulically raised. This was an ingenious way of shortening the length of the cylinders needed to eject the load. Capacity was 25 cubic yards.

Another model BF full-pack with a longer body, and different bracing

Rear view showing reverse-slant tailgate

This push type partial packer with clamshell hopper door was almost certainly a special-order. Note also the auxiliary engine

Here we see yet another full-pack model with the reverse-slant tailgate, with yet another completely different body brace pattern! This late 1950s model also has a much narrower gap between the twin packing cylinders than on the ones discussed above. Also shown are the new Bowles FL-4 "over-the-cab" (OTC) lift arms, which were to become a source of legal wrangling between Bowles and Dempster. This truck was owned by Denver Clean-Up Service.

Color image of another truck similar to the Denver Clean-Up Service truck

Finally a pair of 1959 Bowles partial packers sold by the Arthur E. Bausenbach Co. of Buffalo, New York. For unloading, these push-type packers have a single, high-lift telescopic ram to hoist the body (instead of the typical twin underbody rams).

Bausenbach was the first eastern distributor for Bowles, and according to literature from 1959 had planned to begin manufacturing these in Buffalo. However, there is no evidence that this ever came to pass. By the early 1960s, Bowles had partnered with Converto, and Bausenbach was building their own front loaders using E-Z Pack bodies.

|

1/17/10

© 2010

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

| |