BOWLES LOAD-N-PACK SIDE LOADERS

The explosive growth of the Bowles product line during the end of the decade included the Load-N-Pack, an innovative side loader which first hit the streets around 1958. This was one of the first Drop-Frame type side loaders, built for low-loading, one-man operation. The term drop-frame refers to the modification whereby the frame is cut and lowered between the cab and the rear axle to accommodate the loading hopper of these type bodies. Twin hydraulic cylinders (mounted 'in-line' in the hopper walls) operated a short-stroke packer, which swept refuse from the hopper rearward, up into the body. Packing was progressive, increasing as the body became filled.

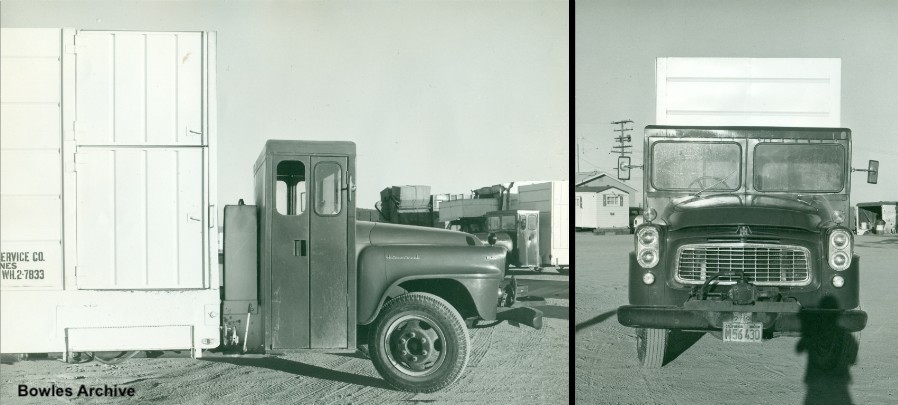

This 1958 International was way ahead of its time. The cab has been modified for stand-up driving from the right hand side. The Bowles Load-N-Pack on the lowered chassis is ideal for one-man operation. The front-mounted hydraulic pump is driven directly by the engine crankshaft, which allows for continuous cycling of the packer even while the truck is in motion.

Another predictive truck is this futuristic REO with right hand drive and setback axle. This is a three-stream truck, with refuse carried in the Load-N-Pack body, and bottles and cans in the two-compartment box, which tilts sideways to dump. It was built by Bowles for Los Angeles By-Products Co. in 1958, during the period of the city's first recycling program. Despite the passage of a half-century, it would not look out of place on the streets of Los Angeles, or any other city.

Here's a GMC chassis ,which has had the frame lowered to accept the Load-N-Pack body. An 18' (25-yard) body sold for $5,900.00 in 1959, which included the frame modifications and mounting. The cab shown here was built by Bowles as a $1,140.00 option, and the conversion to right-hand drive was probably additional as well. A 20' (30-cubic yard) body was also available. Both had a hopper capacity of six cubic yards.

The finished product, in use by Sanitation Service Co. of Santa Barbara

Close up of a Load-N-Pack hopper shows retainer teeth mounted atop passage into body, which helped prevent refuse from falling back into the hopper. Also visible is a sliding door (shown open, above the hopper) on the front wall of the body. This may have been for bulk loading before the body was full, or as a way to gauge how full the body was as loading progressed.

A Load-N-Pack unloads at the dump in the same manner as the front loader

Early Load-N-Pack on Dodge chassis for Trash-A-Way

|

The Shubin-Bowles Controversy

Bowles became involved in a legal fight with John Shubin, who had himself invented and patented a similar side loader (the Shu-Pak) in 1958. Shubin's 1958 patent describes the drop-frame and inverted drawer reciprocating packer system used on the Shu-Pak, which was then being built under license by Western Body & Hoist of Los Angeles.

Bowles did not apply for a patent on the Load-N-Pack until 1960, but we have seen evidence on this page that they were in fact building it in the late 1950s. Differing somewhat from Shubin, the Bowles 1960 patent describes the packer plate as being operated by twin cylinders in-line and to the sides of the packer plate 'drawer' assembly. There is also some photographic evidence indicating Bowles may have used a cross-ram arrangement in later years (which will be discussed at the end of this chapter).

It should be mentioned that the so-called inverted drawer packer was far from being a new idea. The earliest hydraulic rear loaders, made by Jacob Ochsner and Fernand Rey in the 1930s, had each used this method. Ochsner and Rey type packers were well established in Europe by 1958, and the Bowles and Shubin designs were based on that concept. The only difference was that the hopper on the Load-N-Pack and Shu-Pak bodies was located forward, behind the cab, instead of at the rear.

Since the legal proceedings occurred almost fifty years ago, there is not a lot to be found readily on the Internet. From what is available, it would appear that both sides eventually agreed that no infringement had occurred (December, 1961). Yet later, Shubin appears to be attempting to win a jury trial in a 1963 ruling, which seems to have been denied.

When all was said and done, John Shubin and Vince Bowles got tired of paying lawyers. They sat down over lunch, and came up with an agreement; Vince wouldn't sell his side loaders in California. However, he could manufacture them in California, and sell outside of the state.

An illustration of the Inverted Drawer packer appears in the Dennis Album at Classic Refuse Trucks

Also, see the Shu-Pak page in the Western Body & Hoist album here at Classic Refuse Trucks

|

Bowles Pendulum Packer?

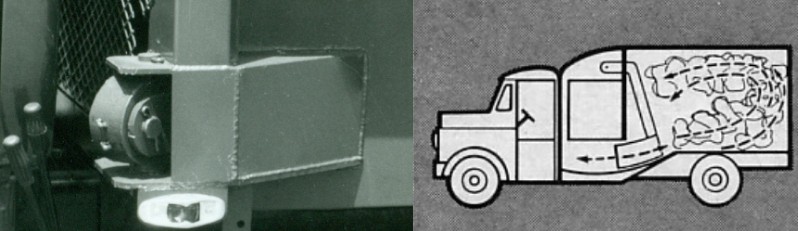

The 1963 Chevrolet shown above carries a Load-N-Pack body with some noticeable changes. What appear to be angle-mounted cylinders are visible at the front of the hopper, and there is a round pin protruding from a plate just above the loading door. This may be a pendulum packer, with arms suspended from the aforementioned pin. Supporting evidence comes in the form of an illustration that was added to the Load-N-Pack magazine advertisement in 1962. The illustration was added to the otherwise identical ad from the previous year. Its addition may have been due to the technical change.

Close up of cylinder mount, and 1962 advertisement illustration

This change to the Load-N-Pack seems to have occurred at about the same time that Bowles and Shubin had settled their differences, and Shu-Pak had started building a similar pendulum packer. It is possible that there may have been some sharing of technology between them, or at least an understanding not pursue suits against one another in light of their prior agreement.

Some of the new style Load-N-Pack models were fitted with straight lift arms to handle small front load containers in addition to their side loading capability. The lift arm cylinders were mounted vertically between the cab and the front of the body, since the drop-frame hopper occupied their normal location. This gave the Load-N-Pack added versatility to handle light containers which it might encounter on otherwise hand-loaded residential collection routes.

In this photo of the hopper, the lift arm cylinder is visible at the extreme right

|

1/17/10

© 2010

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

| |