PAK-TAINER IN THE MID-1960s

In 1965, Cobey became a wholly-owned subsidiary of the Harsco Corporation of Harrisburg, Pennsylvania. Despite the change in ownership, production of refuse vehicles remained at the Cobey factory in Galion, Ohio. The Aldredge-designed models of the early 1960s were replaced with a new Pak-Tainer lift arm designed by Edward Ridgeway and William Appleman. It featured modern bolt-on lift arms, curved slightly to clear the wheel openings when specified for mounting on cab-over-engine trucks. Lift cylinders were relocated under the body, and side litter guards could be fitted over the hopper opening to reduce wind-blowing of refuse.

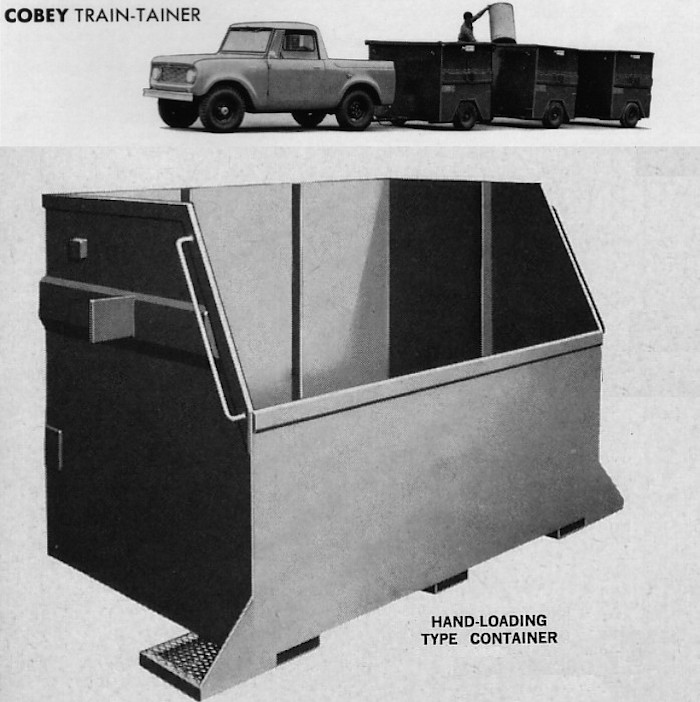

The Cobey Train-Tainer system enabled users to cut costs by towing several wheeled satellite containers (4 or 5 yards capacity) behind a lightweight, maneuverable pickup truck. When full, a Cobey Pak-Tainer "Mother Truck" would empty the containers, allowing the crews to keep working steadily without wasted time driving to the disposal point. The train system was popular with many western municipalities in the 1960s.

A hand-loaded carry bucket was also offered for those who wished to use the Pak-Tainer front loader for household collection. Riding steps and grab-handles were provided for crewmen.

PAK-TAINER; 1967 REVISION

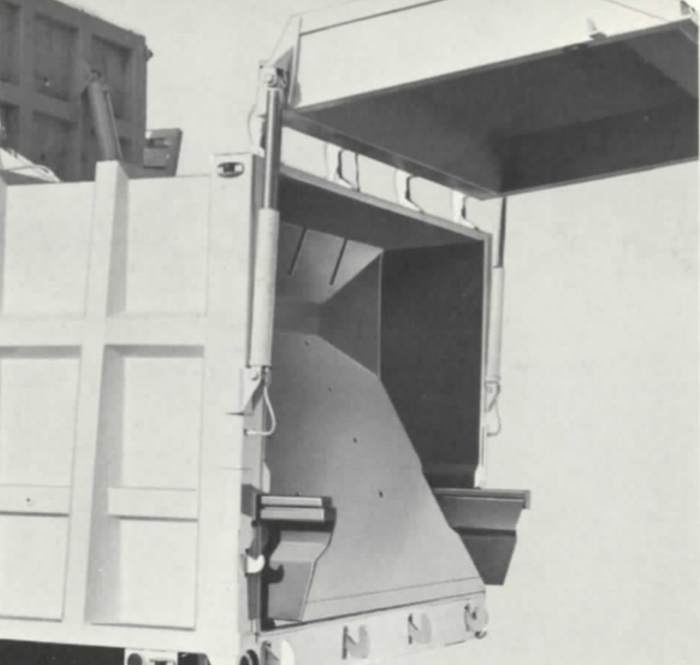

The Pak-Tainer evolved once again in 1967, with an all-new body featuring a single telescopic packer/ejector cylinder, replacing the injection-arm arrangement. Packing force was increased to 78,000 pounds. A new bustle-type tailgate was also added, and over-the-cab lift arms would arrive the following year.

The Pak-Tainer evolved once again in 1967, with an all-new body featuring a single telescopic packer/ejector cylinder, replacing the injection-arm arrangement. Packing force was increased to 78,000 pounds. A new bustle-type tailgate was also added, and over-the-cab lift arms would arrive the following year.

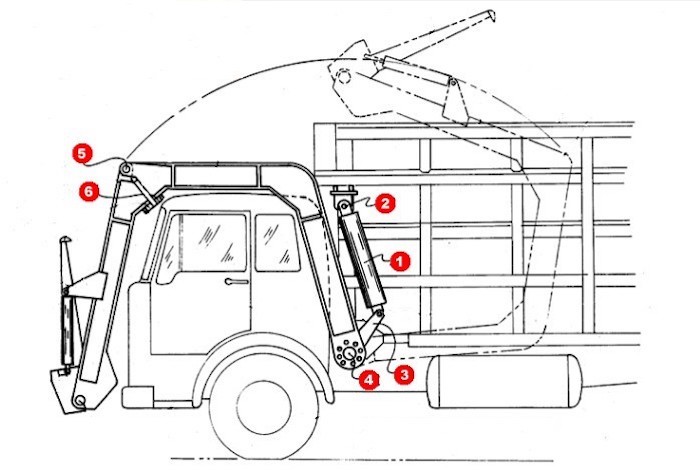

Cobey's new lift arm featured an inside-the-body lift cylinder arrangement, whereby twin lift cylinders (1) were stacked vertically in the dead space behind the packer blade. Their upper ends were attached to gussets welded to the packer body (2), while the lower ends were affixed to cranks (3) connected to the torque tube (4). The lower ends and cranks passed through slots in the floor of the packer body.

The rigid over-the-cab lift arm was constructed on jointed sections, pivotally connected (5) with shock-absorbing rubber pads (5) to protect against stress and strain. Arms were now only configured only for cab-over-engine trucks; conventional-cab arms were no longer available.

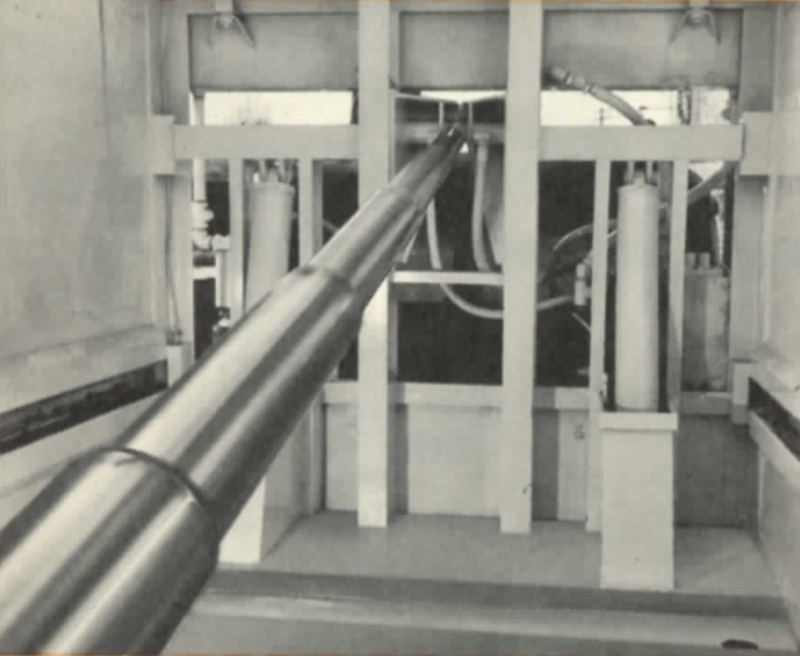

Inside body, looking towards truck cab, the vertically stacked lift arm cylinders are visible

Ejector blade face and tailgate details

|

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3278059 |

Lift and dump apparatus for refuse containers |

Ridgeway, et.al. |

|

November 16, 1964 |

|

US3305263 |

Tail gate latch assembly |

Appleman |

Harsco Corp. |

June 19, 1964 |

1/8/12 (updated 6/12/22)

© 2012

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |