COBEY FLEET-TAINER AND STATION-PAK

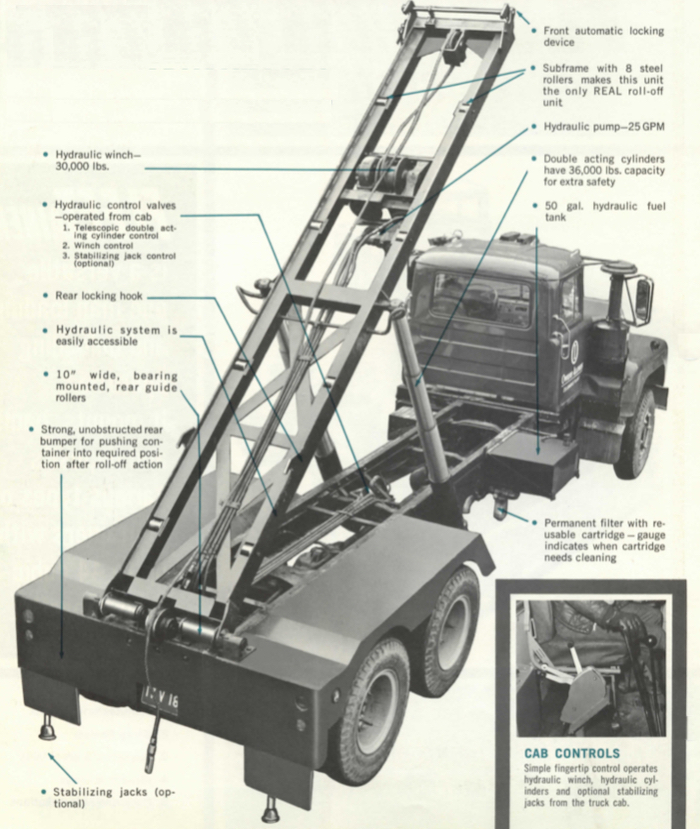

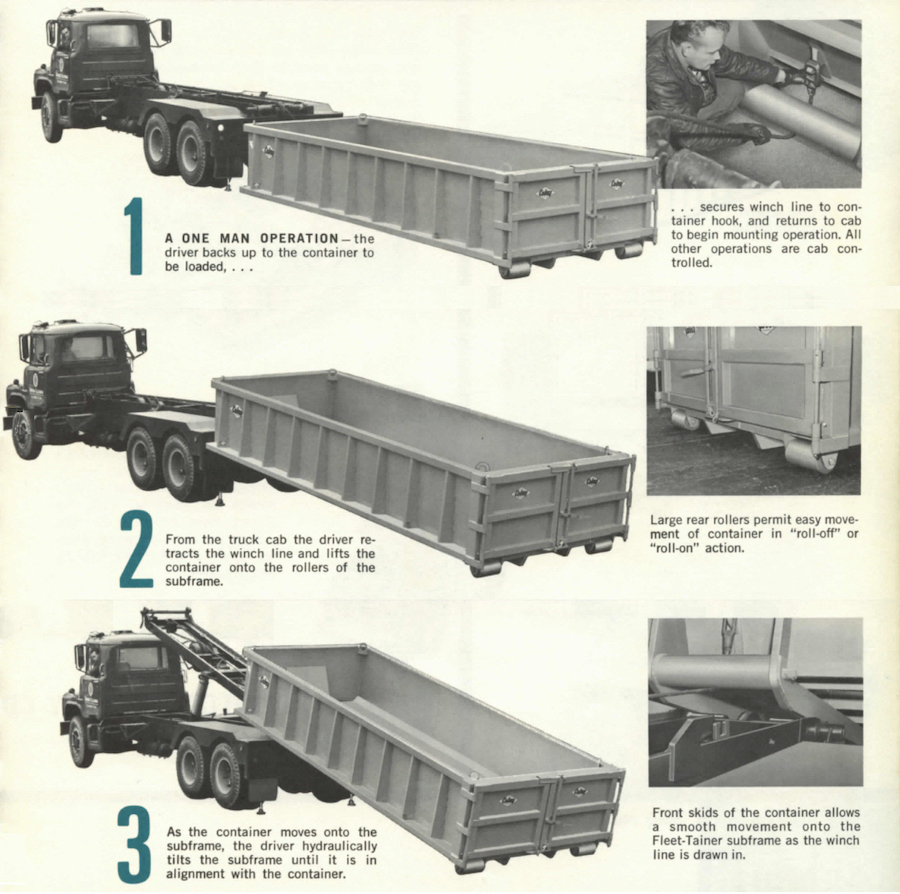

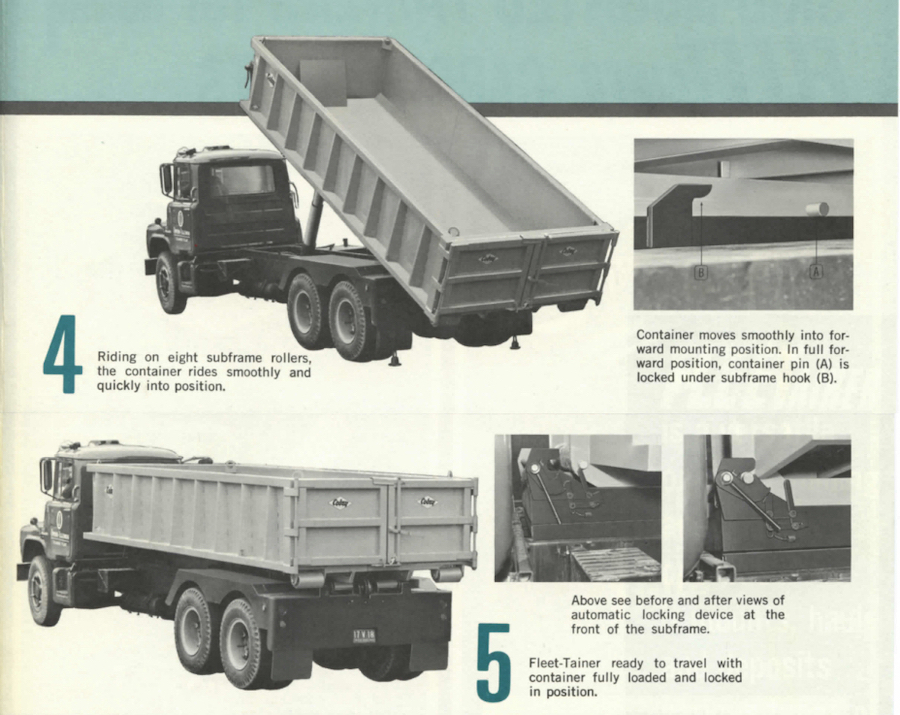

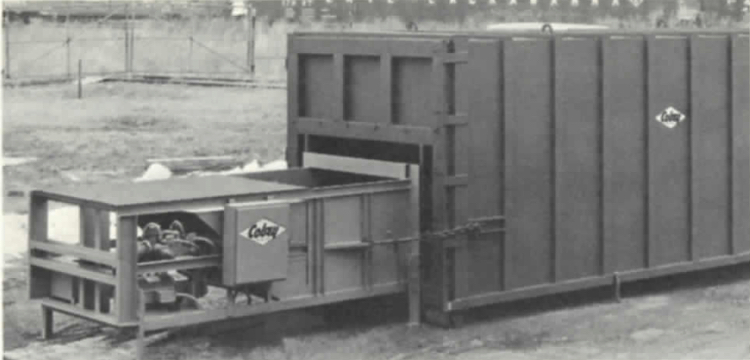

Cobey's first roll-off was the Fleet-Tainer, available as dead-lift or full-frame type unit, and was introduced in 1967. They were paired with either open-type boxes, or enclosed stationary packer boxes used with the Station-Pak system. Other specialized bodies could be adapted to the Fleet-Tainer.

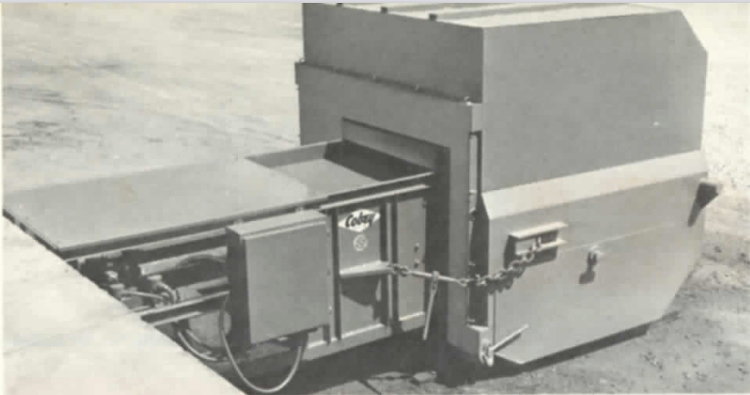

Fleet-Tainer 40-yard box coupled with the Station-Pak unit

Station-Pak unit feeding a 10-yard Liftainer container

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3760962 |

Loading apparatus for demountable vehicle bodies |

Clucker, et.al. |

Harsco Corp. |

August 15, 1966 |

6/12/22

© 2022

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |