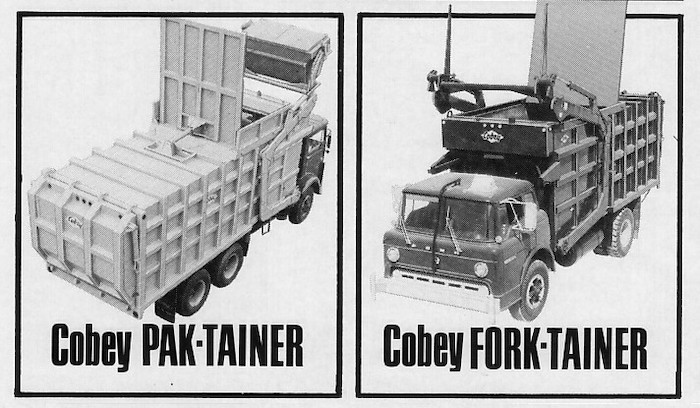

COBEY FORK-TAINER

By the end of the 1960s, Cobey's commitment to the locking jaw and lift-ear method of container coupling used on their front loaders had left them with a dilemma. The side-fork method of container coupling was by now becoming universal within the industry, and customers who already owned Dempster or E-Z Pack bodies would be very unlikely to consider buying Cobey, since their existing stock of containers were incompatible with the Pak-Tainer. To remain competitive, Cobey would need a fork-compatible system.

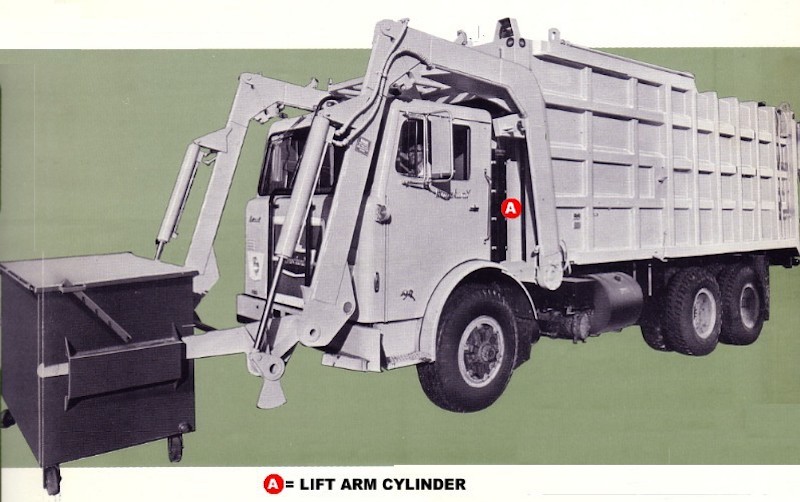

The new Fork-Tainer arrived for 1968 to meet the need, and also introduced a modern over-the-cab lift arm to the Cobey arsenal. However, discontinuing the Pak-Tainer would have alienated existing customers. The solution was to sell both systems, using a common packer body and 6,000 lb. capacity lift arms to save on manufacturing costs. Fork-Tainer container sizes ranged from 2-8 yards, and also a 6-yard stationary compactor container. Pak-Tainer cans were now limited to 3, 5 or 6-yards. The Train-Tainer tow-behind satellite cans were now exclusive to the Fork-Tainer, limited to a single 5-yard offering.

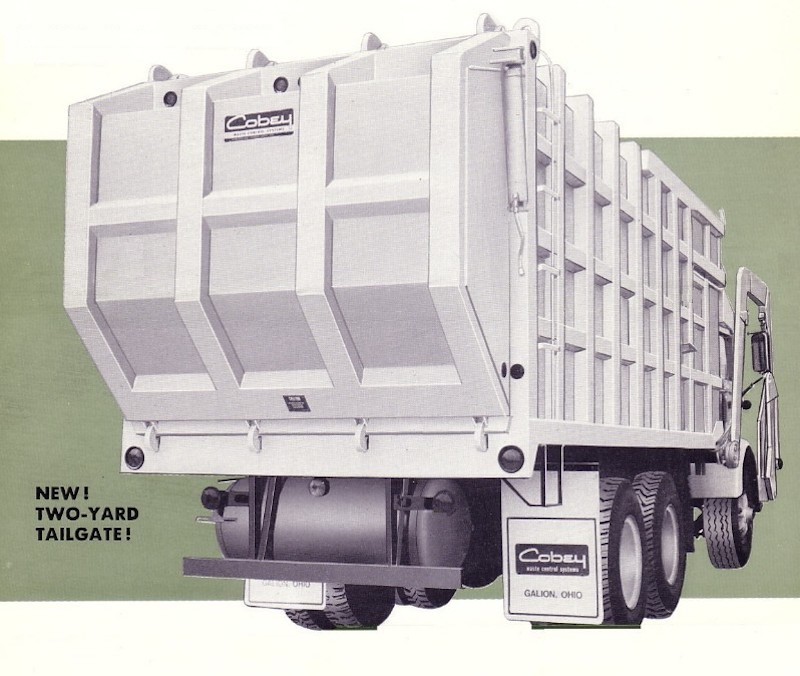

In addition to the new lift arms, Pak-Tainer and Fork-Tainers shared a common packer body in 25 or 31-cubic yard capacities. A single telescopic ram performed all packing and ejection functions. The two-yard bubble tailgate was hydraulically powered, and helped to drive refuse upward to reduce voids in the compacted load. Four hooks, controlled by a single lever at the rear of the body, locked and unlocked the tailgate. At the hopper opening, a hinged cover was standard with mechanical action, with a hydraulic opener optional. Litter screens could be ordered fixed to the sides, or hydraulically actuated at extra cost. A rear-mounted 80-gallon wash-out tank was also on the option list for the new Cobey.

A British version of the Cobey front loader was produced under license by Boughton and sold as the Anchorpac front loader, borrowing its name from Cobey's roll-off/stationary packer product line. These appear identical to their American counterparts. Later models (in both countries) added a small cylinder between the left-hand lift arm and the body, the purpose of which is not clear. It may have been a shock absorber, or possibly part of an automatic leveling circuit.

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3661285 |

Refuse handling apparatus |

Appleman |

Harsco Corp. |

August 5, 1970 |

1/8/12 (updated 6/12/22)

© 2012

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |