Early Dennis, and Post-War Paxit

1940 Dennis moving floor refuse collector

Dennis Brothers Ltd. was founded in 1895, and during its first half century grew to become a powerhouse in truck manufacturing. John Dennis founded the company to build bicycles, and was later joined by his brother Raymond Dennis. The first motorized bicycle appeared in 1899, followed by automobiles (1899), motor trucks (1904), and even power lawnmowers (1922). By the 1920s, the company soon branched out to specialist municipal vehicles such as fire appliances, street cleaners, gulley/cesspit emptiers and of course, refuse collection vehicles. For the latter type, some of the bodies were built in-house, as well as collaborative efforts with others such as Eagle Engineering of Warwick, a firm which would become permanently mated with Dennis a half century later.

Buses of all types were built by Dennis, and an engine manufacturer was bought out in 1933 (White & Poppe). The company survived the Great Depression in good shape, but tragically saw the death of both John and Raymond Dennis in late 1939. In the post-war years, Dennis was squeezed out of the heavy truck market by larger competitors, and increasingly would rely on their municipal vehicles and exports to carry the company. Though not as prestigious as the likes of AEC, Foden or Leyland, the humble but steady municipal market would help Dennis to ultimately avoid the fate of other British truck manufacturers in later decades.

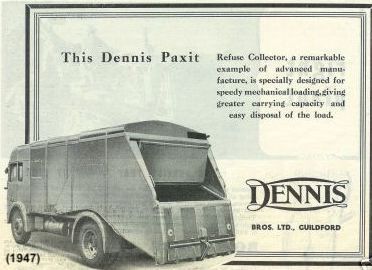

THE PAXIT REFUSE COLLECTOR

The Dennis Hygienic Refuse Collector (HRC) was introduced in 1947, later renamed the Paxit. The name was a clever amalgam of "Pax", the commercial truck model on which it rode, and "compaction" for the mechanism within the body. The Paxit would establish Dennis as one of Britain's premiere builders of compression-type refuse vehicles during the next three decades. Much like their arch-rival Shelvoke & Drewry (SD), they were also one of the few companies that ever successfully produced complete refuse vehicles (body and chassis) in significant numbers. The Dennis Hygienic Refuse Collector (HRC) was introduced in 1947, later renamed the Paxit. The name was a clever amalgam of "Pax", the commercial truck model on which it rode, and "compaction" for the mechanism within the body. The Paxit would establish Dennis as one of Britain's premiere builders of compression-type refuse vehicles during the next three decades. Much like their arch-rival Shelvoke & Drewry (SD), they were also one of the few companies that ever successfully produced complete refuse vehicles (body and chassis) in significant numbers.

The new packer body was made under license from Jakob Ochsner of Switzerland, from a design already popular throughout Europe since the latter half of the 1930s. These utilized a pusher-type blade powered by a single hydraulic ram. When the ram was cycled, the blade pushed refuse from the hopper up an incline, and into the body. As the body became filled, compression of the load would occur. They were "intermittent" type packers, requiring crews to wait until the cycle had completed before reloading of the hopper could commence. To unload, the body was raised by a hoist, and the hinged tailgate was drawn open by a fixed cable system. Since the patented system was licensed worldwide, these early Paxit bodies are nearly identical in appearance to the Ochser versions, as well as the French-made SEMAT Benne OSEM series, the Lewin-Ochsner and probably many others.

THE "CLAMSHELL" PAXIT II

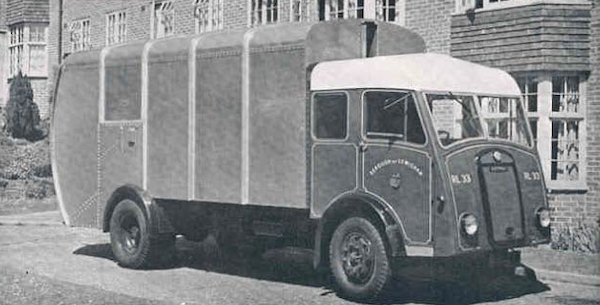

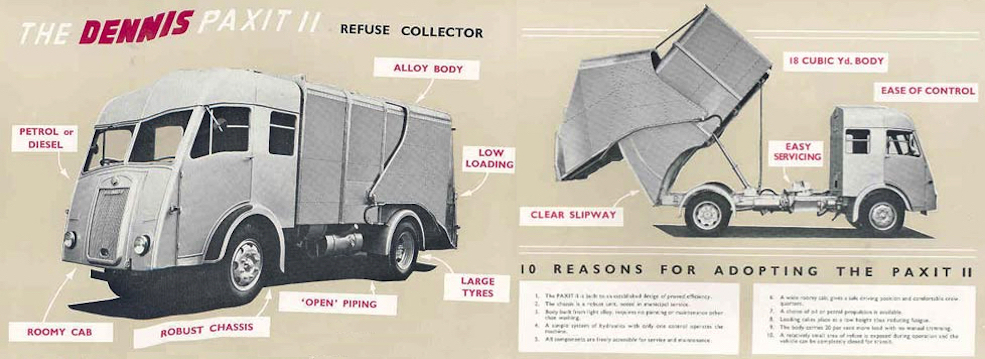

By early 1949, Dennis began to put their own unique stamp on the Ochsner design, with the introduction of a "clamshell" opening body. The packer mechanism was integrated into the roof, which opened under hydraulic power during unloading, eliminating the cable system of the Ochsner. For hoisting, a new direct-lift ram was moved fully forward, and housed in a recess at the front end of the body. Underneath, a stabilizer assembly helped to keep the body steady on the tip. Both the body and the Pax cab panels were made of an alloy called Kynal, which reduced weight and resisted corrosion. This was known as the Paxit II, although Dennis refuse truck nomenclature during this period can be somewhat confusing.

Dennis "clamshell" Paxit 18-cubic yard from a 1949 advertisement

THE PAXIT MAJOR "INTEGRATED CANOPY" TYPE

Yet another change came to the Paxit in mid-1951 with the introduction of an "integrated canopy" style of body with the Paxit Major. The 'Major' designation refers to the heavier rating of the Dennis Pax truck chassis, and the new model was now available with bodies up to 25-cubic yards. The single-cylinder packing blade was replaced by twin rams and a mechanical compensator to keep blade pressure equal if the load became uneven. Outwardly these bodies are distinguished by the absence of a hinged rear canopy, with the loading area at rear being integral with the forward body structure. Within the rear of the structure, the packer mechanism was hinged, and prior to unloading, it was pulled upward towards the roof by hydraulic motors and chains prior to tipping the body.

Paxit Major tipping; note how the packer assembly has been raised within the rear of the body, allowing the load to spill out underneath.

Also seen here is the direct-thrust, front-mounted tipping ram introduced on the 1949 Paxit II.

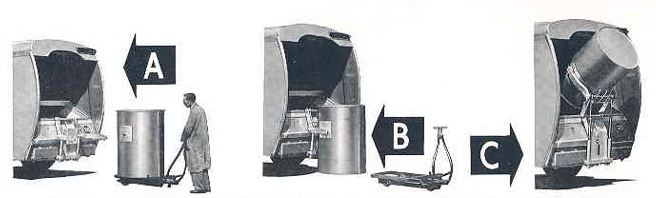

Dennis binlift systems were first offered on the Paxit Major, such as this device for Palladin bins

The clamshell body remained for 18-yard size, simply known as "Paxit" by 1953

PAXIT III

Paxit Major III 22/30 yards capacity

Concurrent with changes being made to the Swiss Ochsner design, Dennis introduced its first continuous-loading model in 1959, the Paxit III. The packer blade was changed to the so-called "inverted drawer" type, which included a built-in follower to prevent refuse from getting behind the mechanism while cycling. Crewmen could add refuse to the hopper at any point in the continuous cycle. At the end of the packer stroke, a pivoting sweeper blade pushed the refuse into the body, compacting and retaining it within. The original, intermittent-loading Paxit II series would remain as an economy model for another decade.

The continuous-loading packer also made possible a whole host of optional binlift and "dustless" loading systems. Large bins could be tipped over the packer, while it churned away automatically until the contents were consumed. Continuous loading had not been possible with the earlier model Paxit. The new Paxit III was a triumph for Dennis, coming just as Shelvoke & Drewry was announcing their first compression-type body, the Pakamatic. Both designs were good, but Dennis had an advantage with their improved 2-stage packer. The rivalry between the firms would not abate for the next three decades.

|

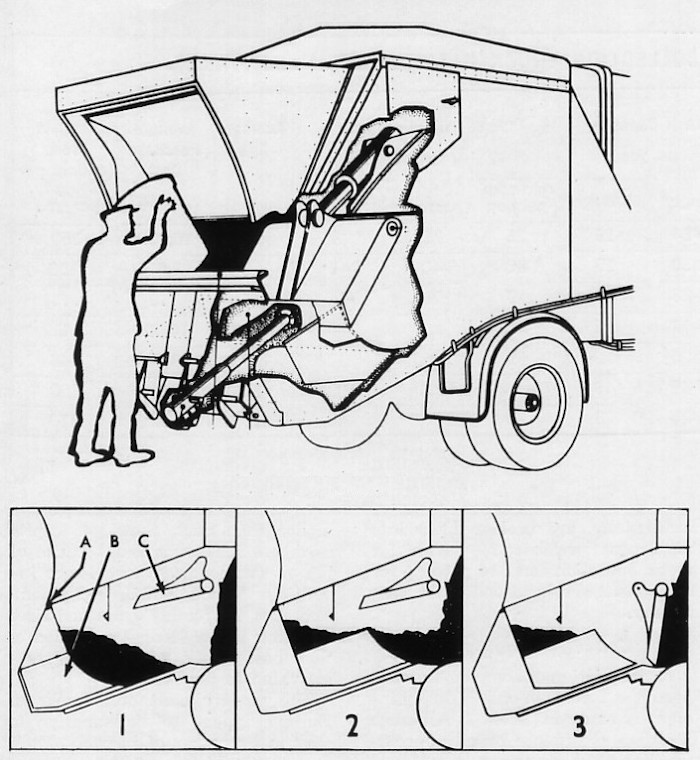

INSIDE THE DENNIS PAXIT III (CONTINUOUS-TYPE PACKER)

|

(1) Refuse is loaded into hopper (2) Plunger B pushes refuse from below, "inverted drawer" shape of plunger prevents refuse from falling behind mechanism (3) Pivoting panel C sweeps and packs refuse into body

Below; view of crushed refuse in Paxit body as packer panel swings open

There is some excellent video of a Paxit mechanism on You Tube

|

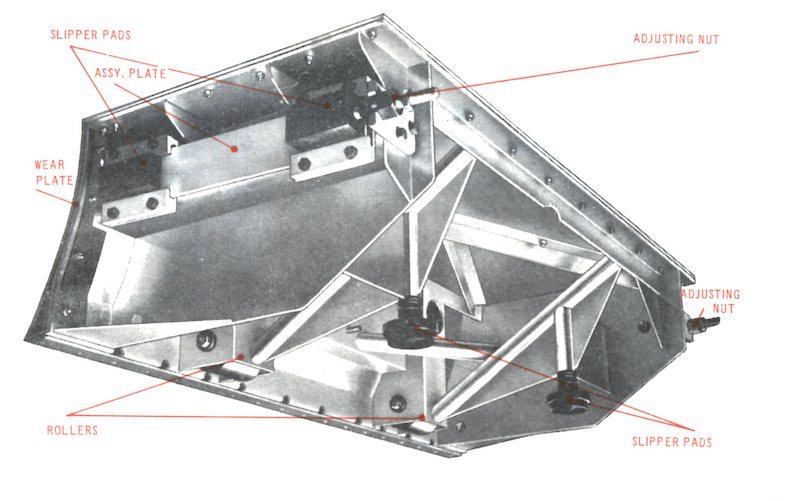

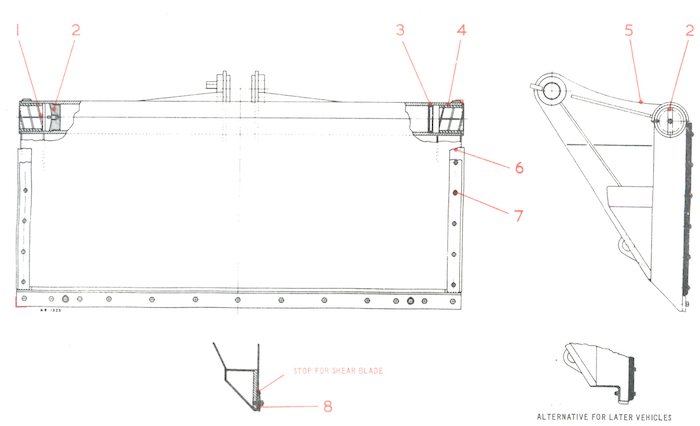

Hopper drawer construction, as viewed from underneath

Packer blade construction

Paxit III 18/25 yards capacity

DENNIS PAXIT II

Even after the introduction of the The Dennis Paxit III, the original Paxit II remained in the lineup as a lower cost stablemate. These were also lighter and somewhat simpler in design. Although mostly overshadowed by the Paxit III, it remained available throughout the 1960s, which is amazing for a design dating to 1935!

|

INSIDE THE DENNIS PAXIT II (INTERMITTENT-TYPE PACKER)

|

The Paxit II used the same packer mechanism as on the first models introduced in 1947.

The Paxit II used the same packer mechanism as on the first models introduced in 1947.

Refuse is first loaded into the hopper, in front of the retracted blade, which rests against the rear wall of the hopper.

|

One the hopper is filled, the packing cycle is started, and the single hydraulic cylinder pushes the blade, moving refuse up the sloped floor and into the body.

One the hopper is filled, the packing cycle is started, and the single hydraulic cylinder pushes the blade, moving refuse up the sloped floor and into the body.

Unlike the new Paxit III, no refuse could be loaded while the blade was in motion, because there is no follower plate to keep it from falling behind the extended blade.

|

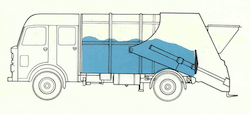

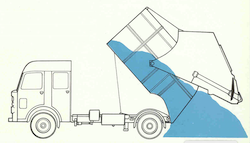

Body is tipped in the conventional manner to unload. Note the cable, with one end affixed to the chassis, and the other to the tailgate canopy. AS the underbody hoist raises the body, the cable automatically raises the canopy clear to allow easy discharge of the load.

Both the Paxit II and Paxit III models use this unloading method.

|

Paxit Major II discharging its load. Twin hoist cylinders were adopted on Dennis tippers to improve stability

REFERENCES:

The Commercial Motor, June 20, 1947, page 50: Hygiene First in New Dennis Refuse Vehicle

The Commercial Motor, January 7, 1949, page 47: Design of Dennis Paxit Changed

The Commercial Motor, June 15, 1951, page 33: Improvements in Dennis Paxit

The Commercial Motor, June 19, 1959, page 34: War on Dust at Cleansing Show (Paxit III)

|

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2076504A |

Vehicle for collecting refuse |

Ochsner |

|

August 17, 1935 |

9/5/22

© 2022

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

|

| |