M-200/C-250/HC-300 Rear Loaders

The replacement for the Super-Hopper rear loaders arrived in 1972, designated as the M-200 for municipal/2 yard hopper (light duty), C-250 for commercial/2.5 yard hopper (medium-duty), and HC-300 for high compaction/3 yard hopper (heavy duty). Again designed by Bill Herpich, the packer mechanism was identical among all models. The packing method was a variation of the conventional slide-sweep system created by Cyril Gollnick on the Leach 2-R Packmaster, but with packing cylinders mounted externally on the hopper, in-line with the trackway and pushing against the slide panel through slots in the sidewalls.

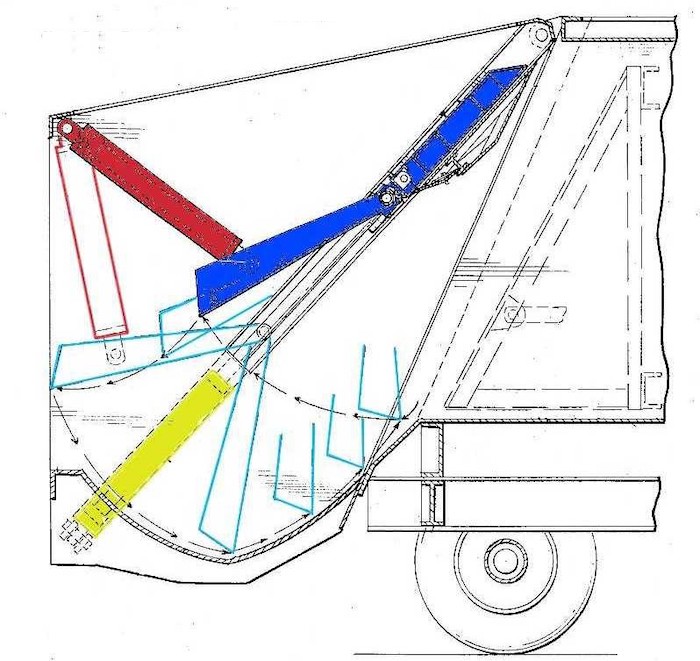

The sweep panel was anything but conventional. It was much larger proportionally to the slide panel. This is the opposite of what is commonly used in slide-sweep designs, then or now. In another departure, the sweep panel cylinders were anchored to the rearward end of the hopper walls, acting somewhat as swing-links and exerting control over the movement of the sweep panel as the slide panel descends in the hopper. However, this is not a true swing-link design in that the slide (upper) panel is guided in roller tracks.

The new E-Z pack was a two panel slide-sweep design with a twist; sweep panel cylinders (red highlights) opened and closed the panel conventionally, and also acted as a type of swing link, imparting a slight lift to the sweep panel as the slide panel descended into the hopper. Inline slide panel cylinders (yellow highlights) were mounted on the outside of the hopper.

|

The positioning of the cylinders allows for a direct thrust to be applied to the sweep panel, delivering potentially high crushing power. This "pusher" design was first used in a rear loader by Dempster on their Route King in 1970. By using the slide-sweep method, E-Z Pack had produced a modern packer delivering excellent compaction (up to 1000 pounds per cubic yard on the HC-300) and a blade that could pass over incompressible or bulky objects. Its predecessor, like the Leach Standard Packmaster, was a captive-travel single panel design which was more susceptible to jamming.

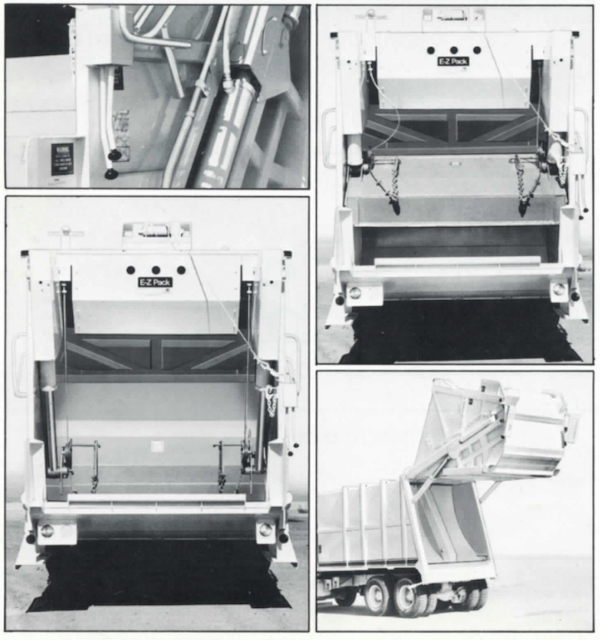

Body sizes ranged from 16 to 25 cubic yards capacity for the M-200, with the beefier C-250 and HC-300 limited to either 20 and 25 yards. Cycle time was advertised as 20 seconds (M-200) with a reload time of 12 seconds. A cable container lift connected to the packer blade could handle 1 and 2 yard containers, while an overhead winch could be ordered for the big cans up to 10 yards.

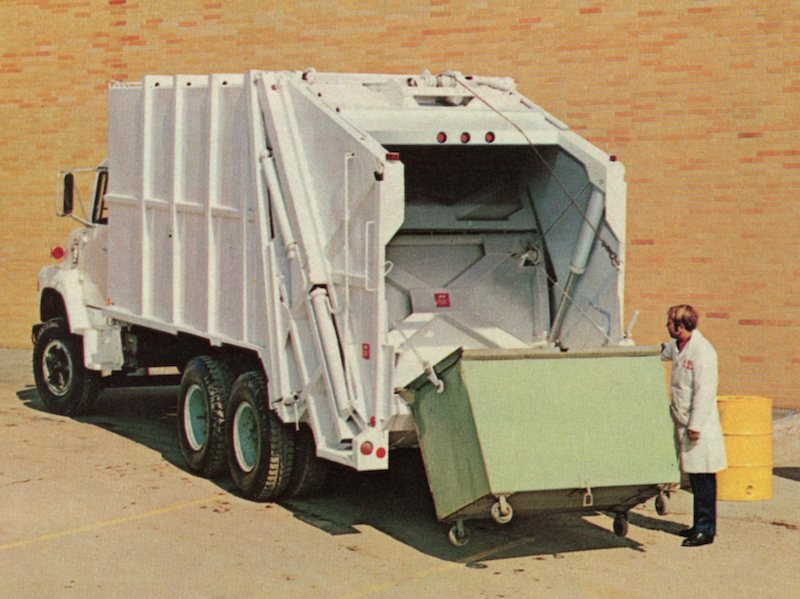

The new E-Z Pack (an M-200 shown here) not only had a wide hopper, but also spacious overhead clearance as well

From a 1972 ad; an E-Z Pack M-200 painted with the ecology flag

Mid-range C-250 shown with optional overhead container hoist

HC-300 high-compaction model was available with a choice of 20, 25 (shown) or 31-cubic yard bodies

The gaping maw of the big HC-300 could swallow three cubic yards of refuse

HC-300 details

An HC-250 used with a satellite container dump vehicle. The tall hopper opeing made the HC ideal as a "mother truck" in these systems

HC-250 pulling a small container with a packer blade cable lift system

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3777917 |

Tailgate for a rear loader refuse vehicle |

Herpich, et.al. |

Peabody Galion |

April 5, 1972 |

10/4/09

© 2009

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |