Chapter 3

Gar Wood Load-Packer

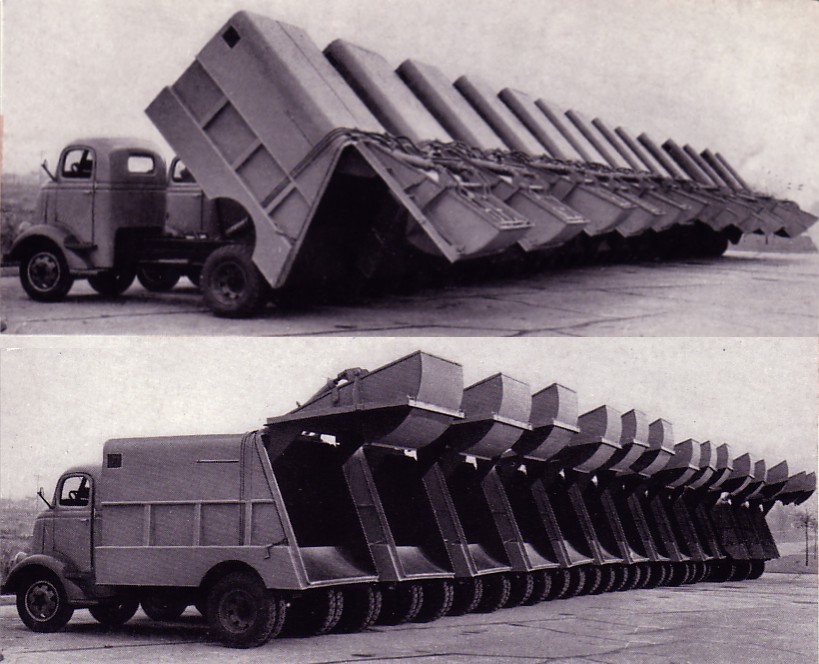

One of the first Load-Packers ever built, a ten yard model on Chevrolet chassis. Montreal bought 18 of them in 1937

Beginning in 1937, Gar Wood, built their first mechanical refuse bodies under contract for the New York City Department of Sanitation (DSNY). These escalator-loader bodies were designed and patented by the DSNY, and both Gar Wood and the Milwaukee-based Heil Company would together build several hundred of them for the department through the early 1940s. As established national body manufacturers, both companies were well suited to the task of building New York's equipment. Heil would subsequently design their own variation of the DSNY escalator-loader for the national market, while Gar Wood moved in a completely different direction with a radical new compactor body called the Load-Packer.

Because the Gar Wood Load-Packer is so often erroneously designated "the first hydraulic refuse packer", it is worthwhile to examine the existing state of the refuse truck industry in the late 1930s. It was still very much a fledgling industry, with many different methods of compactor/loader bodies competing to become the industry standard. The earliest models came out of Germany, where the Krupp auger-screw loader was introduced around 1921, which delivered excellent compaction from a simple design. Shortly after that, Keller und Knappich (KUKA) began selling their famous rotary drum bodies by 1928. Both the Krupp and KUKA were mechanical loaders, with their rotating parts being driven directly from the truck engine.

Left: Krupp developed groundbreaking screw-fed mechanical packer in the 1920s

Right: Rotary-drum KUKA loader was adopted by many German cities in the 1930s

Neither of these designs made many inroads to America, where self-loading, non-compacting 'bucket loaders' were early favorites. The ATIA and Colecto models first appeared around 1928 in the northeastern United States, followed by Leach in 1932. Though early models were not equipped with compaction means, these bodies did employ hydraulic rams to operate the bucket, as well as to hoist and dump the body. The first hydraulic compactor trucks to see widespread use were built in France by Fernand Rey, beginning in 1933. Almost simultaneously, Jacob Ochsner developed a similar two-stage hydraulic packer, which went head-to-head with the ReyLoader for European supremacy. Despite these early advances, it would take almost five years before a compactor body was successfully launched in America.

It is quite probable that Gar Wood Industries was already testing their new body even as they were filling the first order for DSNY escalator-loader bodies. The Load-Packer was a fully enclosed, all-hydraulic compactor designed by George B. Wood, Gar's brother and the chief mechanical engineer for Gar Wood Industries. Unlike the continuous-loading DSNY escalator, the new Gar Wood was a batch loader, with the operator cycling the packer mechanism as often as the loading hopper became filled.

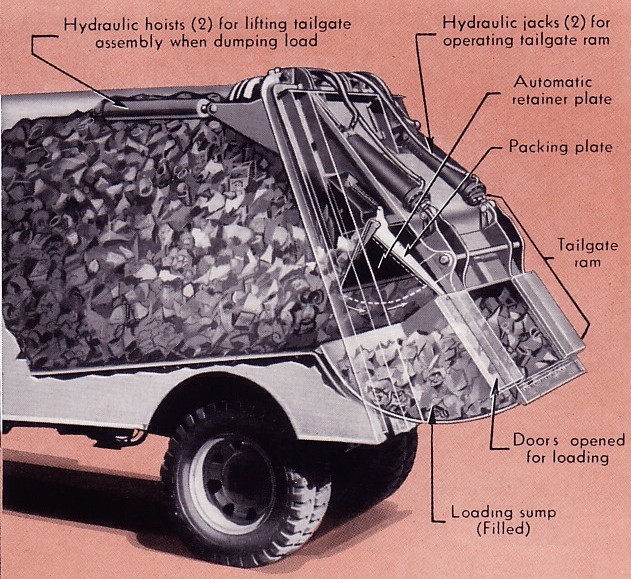

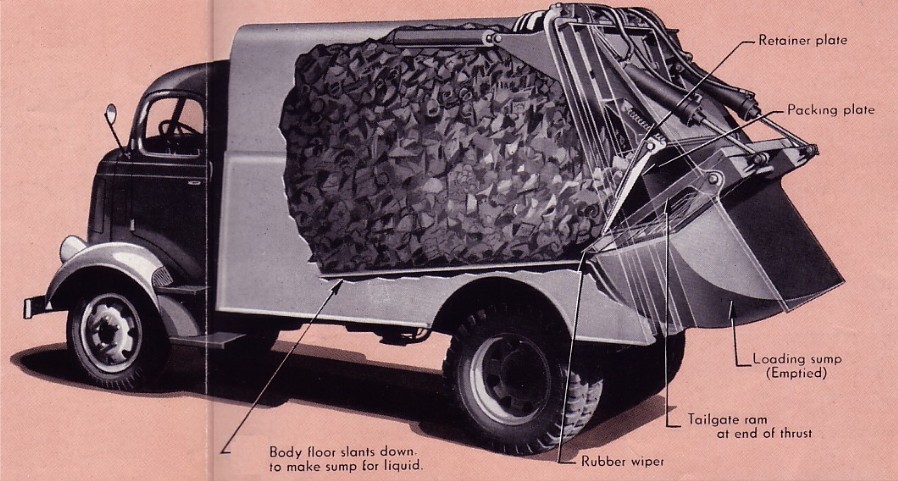

No less than three distinct, but similar versions of the Load-Packer would see production through the next two decades. The first version was built for only a short time, from late 1937 through at least the fall of 1938. It featured and enclosed, watertight main body with a hinged tailgate/packer section attached at the rear, into which the crews loaded refuse. A swinging tailgate ram panel, powered by twin double-acting hydraulic cylinders, worked in conjunction with two internal panels, the packing plate and automatic retainer plate, to load and compress refuse into the body. To empty the load, two hydraulic hoist cylinders raised the tailgate assembly, and the body was tilted by means of an underbody hoist.

INSIDE THE GAR WOOD LOAD PACKER (1937-1938 VERSION)

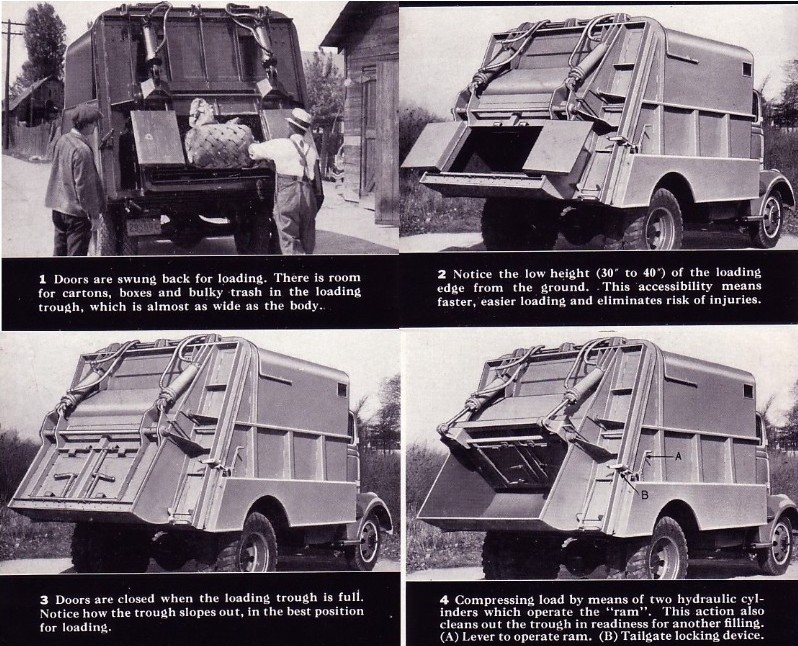

The heart of the Load-Packer was the swinging tailgate ram panel, overlaying and enclosing a loading hopper of about one-half cubic yard capacity. Refuse is loaded through the tailgate ram by manually opening access doors, hinged vertically on either side. Once the hopper was loaded, the crew closed and locked the doors, which then formed the working face of the tailgate ram. Moving a lever started the cycle by releasing a spring loaded "retainer panel" inside the tailgate which snaps back and underneath the packing plate (broken line in illustration). Simultaneously, a valve is opened which allows oil into and the hydraulic cylinders connected to the tailgate ram.

The energized hydraulic cylinders pivot the tailgate ram inward, sweeping the load into the body and contacting the internal packing plate. As the two panels move inward, together they push the loaded refuse into the body as the packing panel scrapes and the refuse from the tailgate ram. As loading further progresses, the retainer panel scrapes refuse from behind the packer panel. At the end of the inward thrust, the loaded refuse is held in the body by the retainer panel, which automatically locks into place.

To complete the cycle, the operator moves the control lever again, reversing the tailgate ram back through the hopper, followed by the spring-loaded packer plate back into the loading position, ready for the next batch of refuse. Both the internal packer and retainer panels have no direct power means, being operated solely by the movement of the tailgate ram panel, and returned by heavy extension springs.

|

The City of Montreal, Quebec would be the first municipal fleet to adopt the Load-Packer. In 1937, they purchased eighteen Load-Packers of which fourteen were 10-cubic yard models and the rest were 18-cubic yard semi-trailers. The city reported considerable savings with the modern Gar Wood packers, which replaced the old fleet of thirteen dump trucks and 35 horse-drawn collectors. Crew size was reduced from four to two men per truck or trailer. That same year, The Town of Tonawanda, New York became the first in the United States to purchase a Load-Packer.

Although the Load-Packer had some mechanical components, it was primarily a hydraulic-powered refuse loader. Depending on the type of refuse collected, it could reduce load density 50% or more. Additionally, it could handle virtually any waste stream desired, and was liquid-tight. Though not a continuous loader, it offered better fuel economy, since the loading mechanism was cycled only intermittently. In load capacity and loading height, it was a big improvement over conventional bucket loaders of the 1930s, and would displace them almost completely within about fifteen years.

Though it wasn't truly the first in the industry, the Load-Packer would be the first commercially viable refuse packer built in North America, and a remarkably clean design by the standards of the late 1930s. It established Gar Wood as the leader of the refuse body market early in the game, and began to win over buyers hesitant about mechanized collection units. Moreover, the Load-Packer pointed the way to what was ultimately to be the vaunted "industry standard", as the rear-load packer truck, in one form or another, came to dominate the American market during the 1950s and beyond.

Fourteen Load-Packers bought by Montreal in 1937

Tonawanda NY: First Load-Packer sold in the United States

7/30/14

© 2014 Eric Voytko

All rights reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

| |