Chapter 4

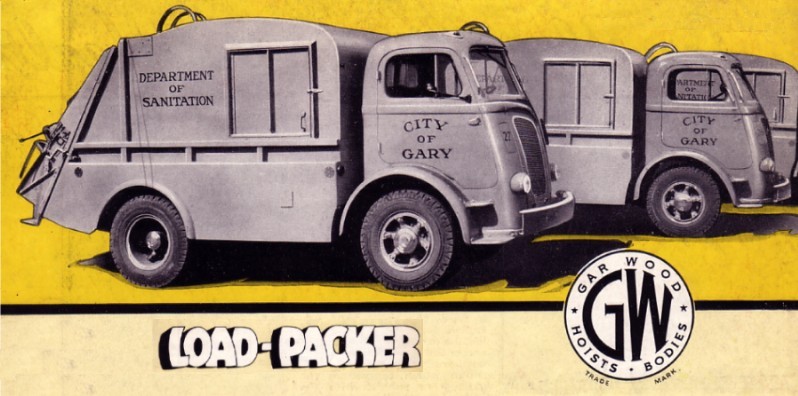

Load-Packer

(Second generation, 1938-1952)

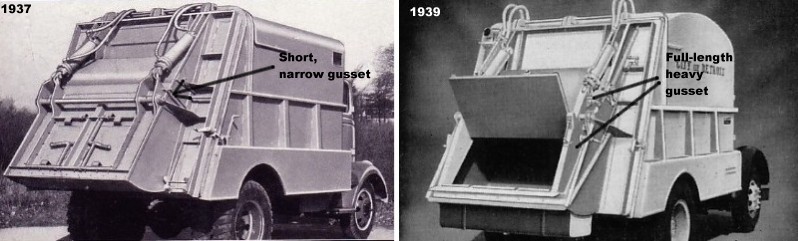

Shortly after introduction in 1937, the Load-Packer underwent significant engineering changes to the packing mechanism. The most visible change occurred at the tailgate ram panel, with the barn doors on of early-production models being replaced by a single spring-loaded, top-hinged door. Refuse was still loaded through the open tailgate ram, the door then being closed and latched shut prior to starting the packing cycle. In later years, the men who operated them sometimes referred to these models as the “Slam-Door” Gar Woods.

On the inside, the redundant internal packing plate used on the 1937 model was completely eliminated, and its function was combined with that of the automatic retainer plate. The entire tailgate ram assembly was beefed-up, adding strengthening ribs to withstand the stresses of compression. The gussets that attached the hydraulic cylinders were enlarged to run the full length of the ram panel assembly.

Improved model Load-Packer of 1939 featured top-hinged loading door, strengthened tailgate ram gussets.

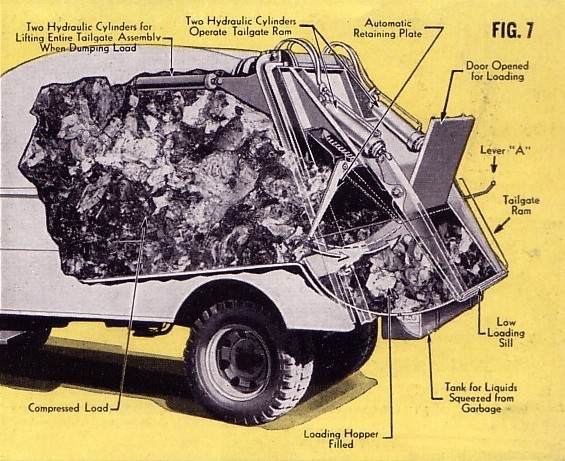

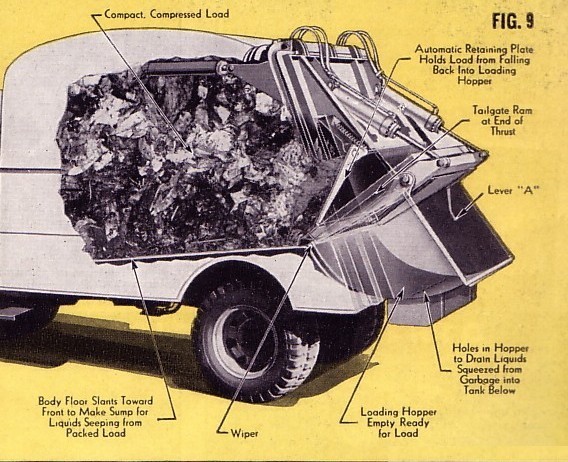

INSIDE THE GAR WOOD LOAD PACKER (1939-1951 VERSION)

The most visible change to the 2nd generation Load-Packer is the top-hinged charge door in the tailgate ram, replacing the side hinged barn doors of the early model. Operation was simplified, and the component was stronger and better able to withstand packing pressure.

The most visible change to the 2nd generation Load-Packer is the top-hinged charge door in the tailgate ram, replacing the side hinged barn doors of the early model. Operation was simplified, and the component was stronger and better able to withstand packing pressure.

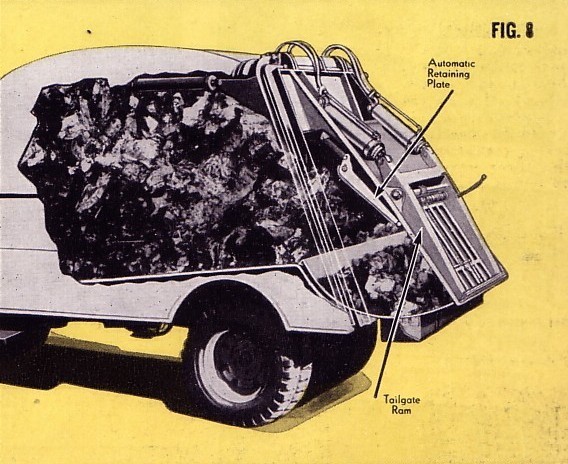

Note that the internal packing plate used on earlier models has been eliminated. The automatic retainer plate has been enlarged, and takes the place of the internal packing plate.

In this illustration, the door is open for loading, and the compacted load is held in the body by the automatic retainer plate.

|

To begin the pack cycle, the operator first moves a lever that releases the spring-balanced loading door from its open position, to the closed position. Automatic catches lock the door together with the tailgate ram, ready for packing.

Next, operator pulls the packer control handle. This releases the spring-loaded automatic retainer plate, which snaps back over the loaded hopper, and against the inside of the tailgate ram.

|

Simultaneously, the pack cylinders are energized and the tailgate ram moves inward, pushing refuse from hopper into body, while also pushing in the retainer plate, which scrapes refuse from the inside of the ram panel. As the ram panel reaches the limit of its inward travel, the spring-loaded automatic retainer plate locks in place, holding the compacted load within the body.

Simultaneously, the pack cylinders are energized and the tailgate ram moves inward, pushing refuse from hopper into body, while also pushing in the retainer plate, which scrapes refuse from the inside of the ram panel. As the ram panel reaches the limit of its inward travel, the spring-loaded automatic retainer plate locks in place, holding the compacted load within the body.

The tailgate ram reverses automatically, releasing the loading door latches when it reaches the limit of its outward travel. The operator then raises the door to the locked-open position, ready for the next load.

Total cycle time is 15-20 seconds. Since the ram panel had to reverse its travel back through the hopper, no additional refuse could be loaded until the entire cycle had been completed.

|

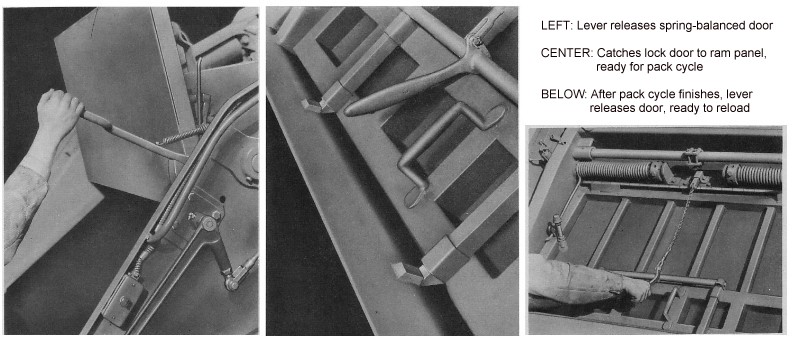

TOP-HINGED LOADING DOOR DETAILS

Left: A hand-operated lever releases the loading door prior to start of pack cycle.

Center: Automatic catches lock door to tailgate ram assembly, ready to pack

Right: door releases automatically at end of cycle, or can be manually released

|

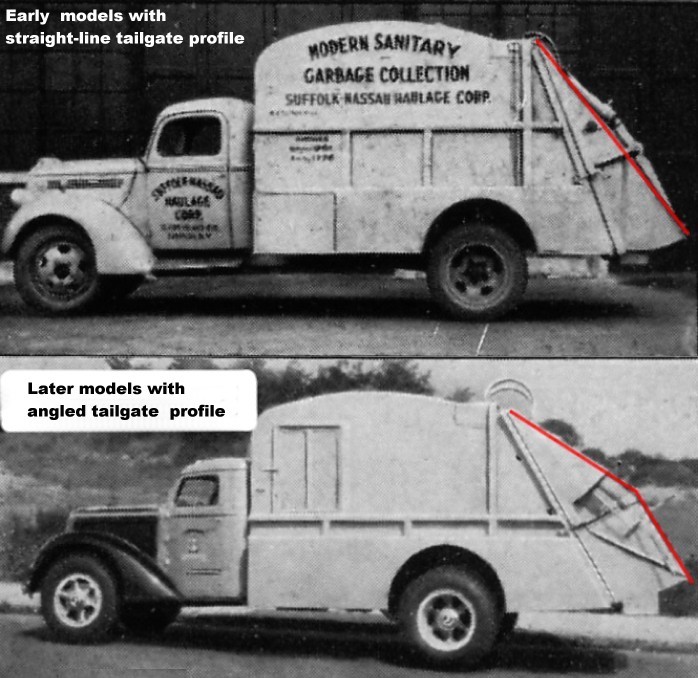

TAILGATE STRUCTURE CHANGE (CIRCA 1940)

Improvements were constantly being made to the Load-Packer. Models made between 1937 and 1939 had a "straight-line" tailgate profile. The packing cylinders and tailgate ram are visible when viewed from the side. This includes both barn door and top-hinged door versions.

Starting around 1940, this straight-line style tailgate was replaced by an angled profile tailgate, which better supported the tailgate ram pivot bearings, and added strength the entire structure. Note the packing cylinders and tailgate ram are concealed when viewed from the side. This new style tailgate was continued after World War II, and lasted through 1952.

|

This 1946 Load-Packer purchased by the City of Mansfield, Ohio shows the post-war streamlining of the tailgate assembly. The overhead hydraulic lines are now concealed, as are the packing cylinders, which only become visible when the tailgate ram is in operation, as seen here.

In 1948, the New York City Department of Sanitation (DSNY) bought 200 Gar Wood Load-Packers on Autocar C-50 chassis,

to shore up their fleet of aging escalator-loaders, some of which had been in service for over a decade.

The City of York, Pennsylvania acquired this C-50 Autocar with a Gar Wood Load-Packer body in the summer of 1950.

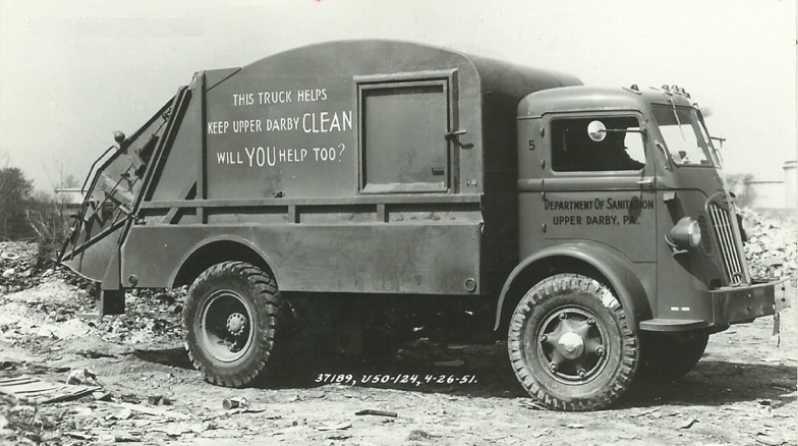

Load-Packer on a streamlined 1951 Autocar U-50 cab-over-engine (COE) truck. Post-war models were available in 9, 12 and 16-cubic yard capacities.

White 3000 tilt-cab with Gar Wood Load-Packer, feeding the hogs

1940s-50s-era REO with Gar Wood Load-Packer for Wichita

Although early Load-Packers are sometimes referred to as the "LP-100" series, there has yet to surface any conclusive proof of this as an official series designation in factory advertising, brochures or service manuals. To the contrary, one identification plate from a surviving 1940s body simply designates the model as "L-P", followed by a sequential serial number and the body capacity. Load-Packer series identity did not officially begin until the LP-200 was introduced in 1952.

The back of the automatic retaining plate, as seen with the tailgate partially raised. There are very few original Load-Packers left, and this is the only known restored example, a late-1940s model saved and reconditioned to perfect working condition by Lou Carollo.

A nice new 1946 Ford/Load-Packer for Dearborn, Michigan

At the time the Load-Packer was introduced in the late 1930s, Garfield Wood was beginning to distance himself from the company bearing his name. The death in May of 1938 of his younger brother Logan Wood was undoubtedly was a factor in Gar's divesture. As Vice President and General Manager, Logan had ably run the day-to-day operations of the manufacturing empire since the 1920s. In August of 1939, the bus-building division Gar Wood Motor Coach was sold to American Transportation Corporation after only a few years in operation. Just before the outbreak of war in 1941, John J. Bergen & Co. of New York bought a 57% interest in Gar Wood Industries. At 65 years of age, Wood sold his remaining interest in the company to outside investors in 1945. He enjoyed a lengthy retirement in Florida, buying the Fisher Island estate where he spent his remaining years.

As for the Load-Packer, it would solidly position Gar Wood Industries as the undisputed leader in compaction refuse bodies in America, both before and after World War II. Upon fulfillment of war contracts, truck body production resumed, and the Load-Packer returned mostly unchanged. With no domestically produced rear-load packer to challenge it, the early post-war years were very good for sales. This early sales lead also translated to brand-recognition and customer loyalty, which would benefit the company for decades. However, competitors were not sitting idly by as Gar Wood gobbled up more and more of the market. The Load-Packer would prove to be a somewhat archaic design within a few years, as these rivals began to field competitive, and arguably, superior post-war designs.

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2212058 |

Refuse Handling Truck Body |

Wood |

Gar Wood |

August 23, 1938 |

7/30/14 (updated 8/28/21)

© 2014

All rights reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

|

| |