Chapter 5

Post War:

Gar Wood Bucket Loader and St. Paul Pax-All

Although Garfield Wood had completed the sale of his company by 1945, the new owners of Gar Wood Industries wisely left the name unchanged. Already a world-renowned manufacturer and industry leader, even more expansion and diversification began in the years following World War II. One such example was the acquisition of Buckeye Traction Digger of Findlay, Ohio, a manufacturer of construction equipment that was added as a division in 1945. At the other end of the spectrum, Gar Wood Boat Division of Marysville was permanently shuttered in 1947. Despite having always produced the highest quality watercraft, it had primarily been a "pet-project" of Garfield Wood. With shareholder profit now a prime consideration, its losses could no longer be tolerated.

To better serve what was the fastest growing truck market in the United States, a west coast division was opened in San Francisco in 1946. This branch quickly expanded, and then moved to nearby Richmond in May of 1948. The majority of truck equipment production remained at facilities throughout the City of Detroit until 1949, when a new factory was opened in the northern suburb of Wayne, Michigan. By late 1950, all Detroit-area operations were consolidated there. This would eventually be renamed Wayne Division, which built dump trucks, trailers and the famous Load-Packer refuse bodies.

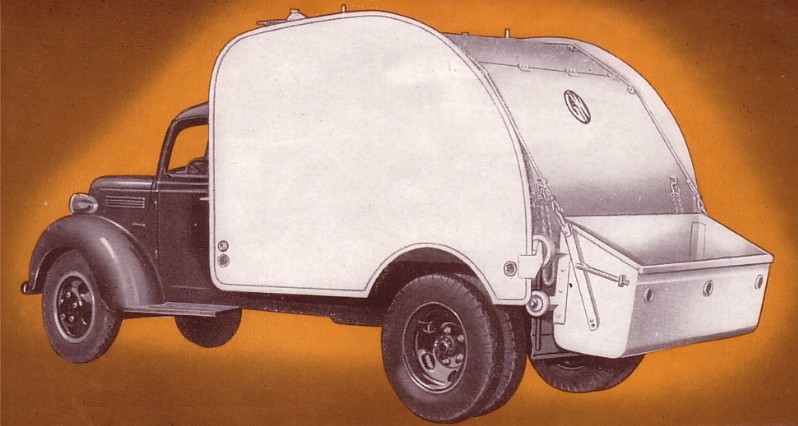

Following the war, the Gar Wood Load-Packer was virtually unchallenged, being the only mass-marketed rear-load refuse packers in America. While the Load-Packer remained unchanged from the pre-war design, a new refuse truck was introduced in 1946 called the Gar Wood Bucket Loader. This non-compacting self-loader was most likely created to compete with the Leach Refuse Getter and the Colecto, the latter having been recently been acquired by the Heil Company.

The Bucket Loader was lightweight and simple, with a single hydraulic cylinder and roller-guided trough that was raised by steel cables (anchored to the chassis) as the body was hoisted. No packer plate was used, but some gravit packing occurred as the body was being tilted with each dump cycle. It was economical to mass-produce, and attractive to cash-poor municipal customers and smaller contractors.

Rare Gar Wood Bucket Loader on International K-series with body side reinforcements

Cable gear that operated the bucket as the body was raised hydraulically

Woodson/St. Paul Pax-All

George Wood, Gar's brother who had designed the original Load-Packer, formed his own company following the sale of Gar Wood Industries. A joint venture with his son, the Detroit-based upstart was named appropriately Woodson Products. Along with a small dump truck body, they also produced a new 12-yard bucket loader for refuse collection called the Woodson Pax-All.

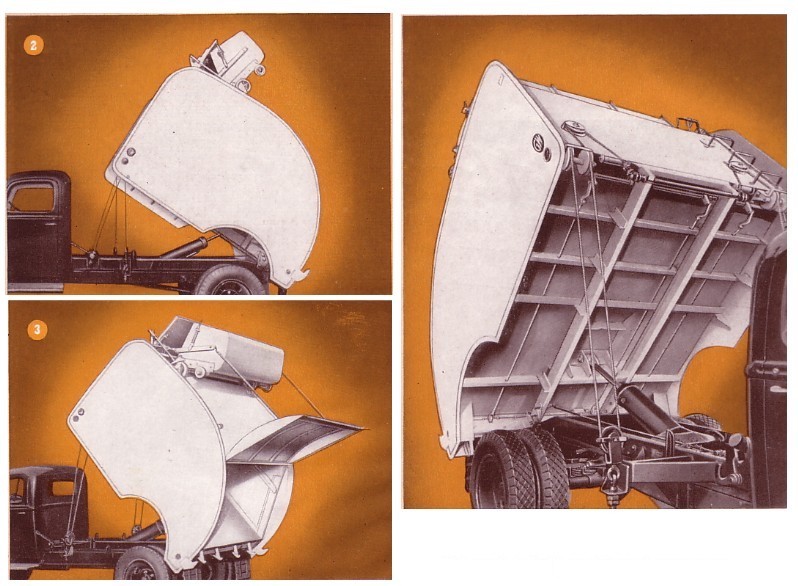

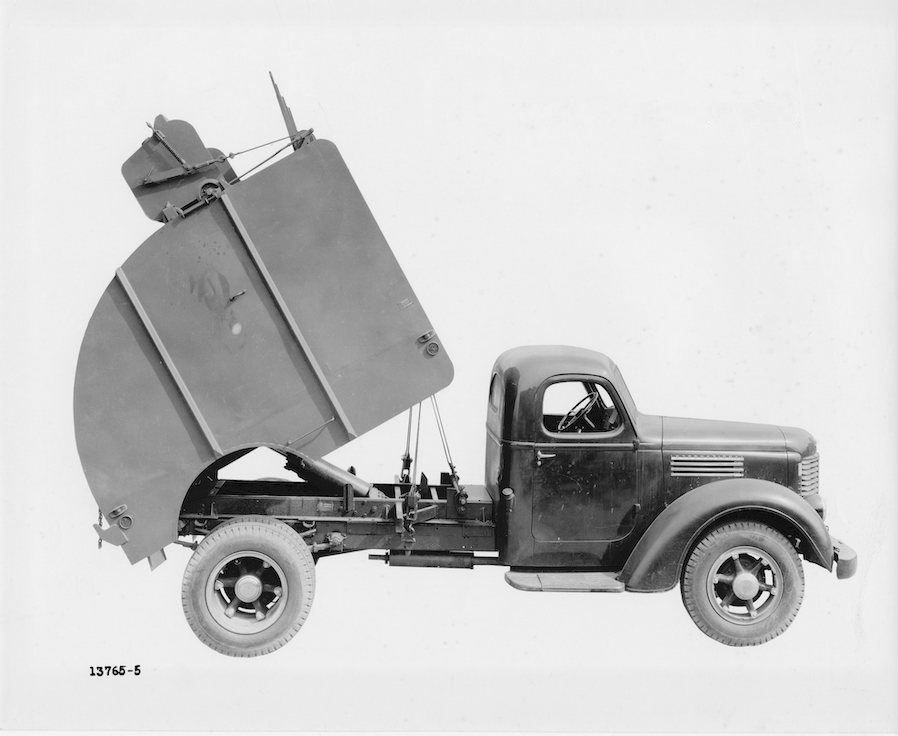

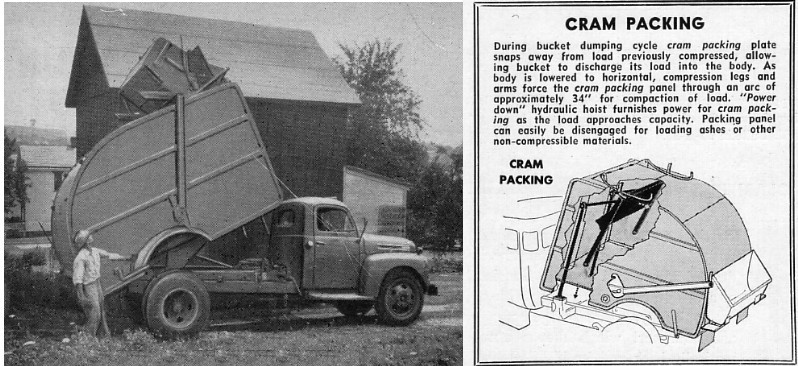

The Pax-All worked much like the Gar Wood Bucket Loader, with a cable-operated trough dumping into the top of an enclosed body. However, rigid stabilizer arms supported the trough, in lieu of roller wheels used on the Gar Wood model. The biggest difference was inside the body, where a "Cram-Packing" panel was added, automatically retracting as the body was raised and the trough load was dumped. As the body lowered, the panel then extended rearward, compacting and retaining the load.

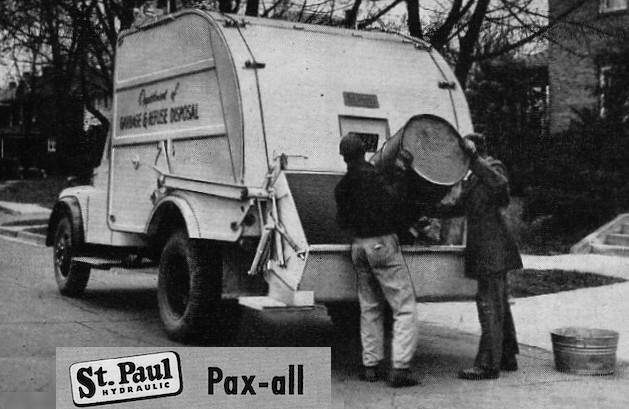

In 1950, George Wood sold the rights to the Pax-All to Gar Wood Industries, and it was subsequently added to the catalog of their St. Paul Hydraulic Hoist subsidiary. The purchase of Pax-All was clearly in response to improvements to competitive bucket loaders, which had added internal compaction plates. The St. Paul Pax-All appears to have wholly replaced the Gar Wood Bucket Loader in the company product line. It remained in production until some time the late 1950s, when bucket loader bodies were being made obsolete by rapid advances within the industry. Thus, the Pax-All, along with the Leach Refuse Getter and Heil Colecto-Pak quietly faded from the muster rolls. In 1958, the Pax-All trade name was transferred, being applied to the wheeled container and hoist system used on Gar Wood rear-load packers.

Raising the Pax-All body pushed against cables which simultaneously elevated and dumped the bucket.

Lowering the body returned the bucket, and moved internal Cram-Packing panel rearward.

When not hauling garbage, Rankin, Pennsylvania used their Pax-All for hauling dirt for street maintenance crews.

Emptying a 55-gallon barrel into the bucket.

Bottom view shows Cram-Packing panel linkage under front of body.

To unload, the tailgate is unlocked, and attached (by cables) to the bucket lift arms which raise the gate as they ascend.

As the body tilts, the cram-packing panel helps assist in pushing out the load.

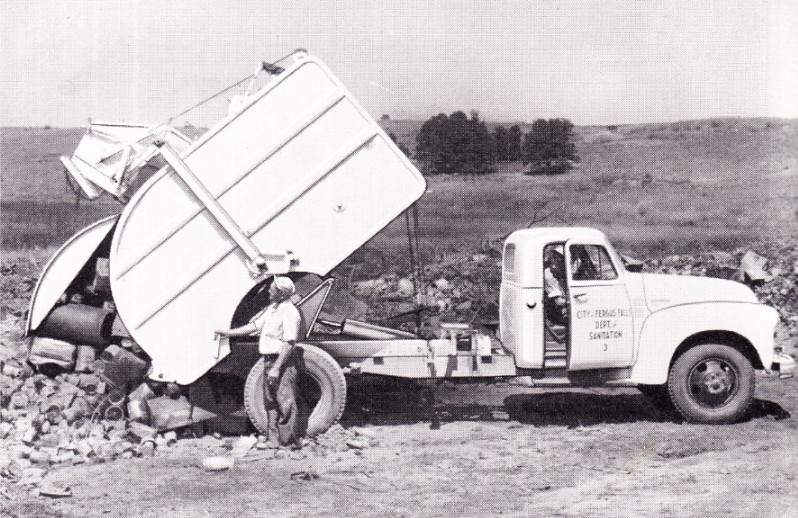

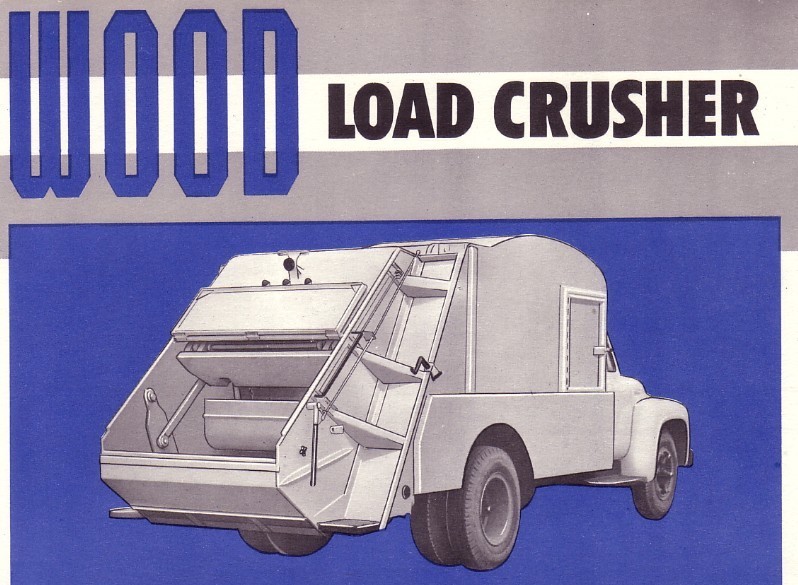

Wood Load-Crusher

Mfg. by Phil Wood Industries of Windsor, Ontario

George Wood designed at least one more famous refuse body, originally sold as the Herman Ram-Pak, and later sold to Daybrook Hydraulic who changed the name to Power-Packer. In Canada, the design was sold as the Wood Load-Crusher and was manufactured by Phil Wood Industries of Windsor, Ontario. Phil Wood was another of Gar's brothers, who had run the Canadian division of the company for many years. Following World War II, he bought the division and renamed it after himself.

It should be emphasized that the Load-Crusher was not a product of Gar Wood industries, but is mentioned here because of the connection to the Wood family. In addition to complete bodies, Phil Wood Industries marketed the Load-Crusher tailgate as a bolt-on conversion kit for older Gar Wood Load-Packers. Phil Wood sold his company in 1959, and died in 1972.

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2511556 |

Mechanical packing device for dump trucks |

Wood |

|

September 20, 1948 |

7/30/14 (updated 8/28/21)

© 2014

All rights reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |