Chapter 6

Load-Packer 200 Series

1952-1957

Like most other manufacturers, Gar Wood Industries had continued much of their pre-war products through the late 1940s to quickly supply pent-up demand. Also like other manufacturers, they were pressed into defense contracts once again when war broke out in Korea during 1950. As during the Second World War, Gar Wood was in the enviable position of being an established producer of civilian products that were also used by the military. For instance, auto manufacturers might be required to allocate plant space for production of tanks, rifles or munitions, and then convert these resources back when hostilities ended. Gar Wood already produced items in high demand by the armed forces, including hydraulic equipment, winches, cranes and truck bodies. Even Load-Packers were needed for stateside refuse collection at military bases.

The Load-Packer entered the 1950s having changed little since 1940, along with its recently acquired stable-mate, the St. Paul Pax-All bucket loader. The last of these early-style Load-Packers were built in the summer of 1952, with 140 units alone going to the New York Department of Sanitation (DSNY). Including this shipment, the Big Apple had one of the biggest Gar Wood fleets in the world, with 640 Load-Packers. Worldwide, there were four times as many Load-Packers in service as all other makes combined. However, competition within the refuse body industry was beginning to intensify, as Gar Wood contended with not only the Sicard Sanivan, but now also the Leach Packmaster which had been recently introduced. Heil's all-new Colectomatic was but a year away, and was probably not unknown to the management at Gar Wood.

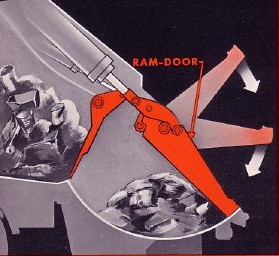

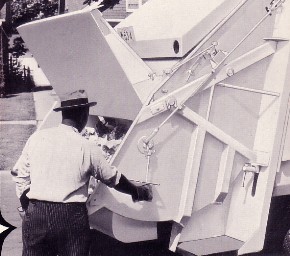

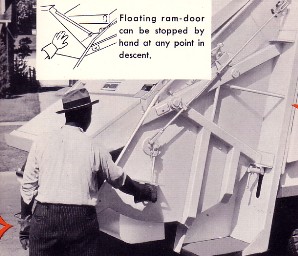

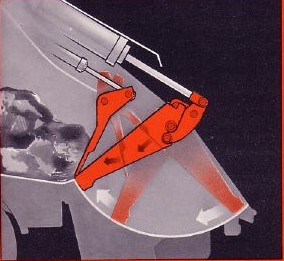

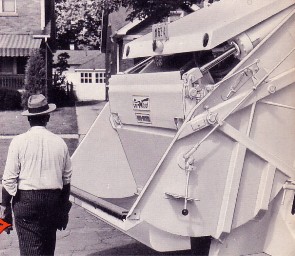

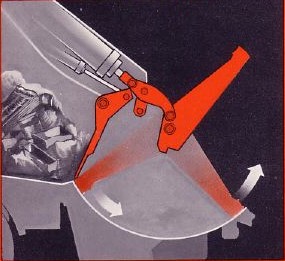

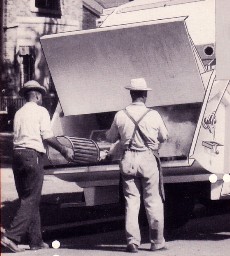

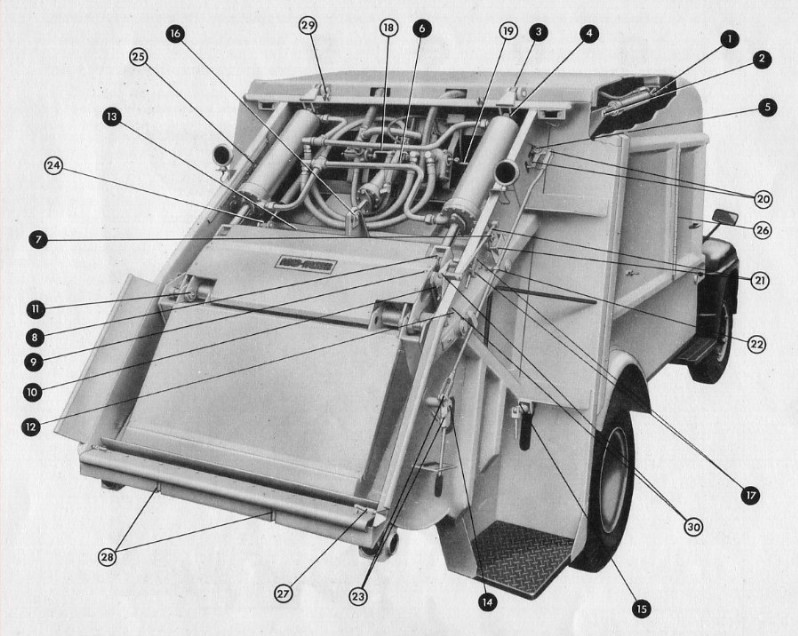

To keep their industry-leading position, Gar Wood unveiled the Load-Packer 200 series in September of 1952, the third and final variation of George Wood's original 1937 design. It was designed by Norbert T. Starr and was clearly in development for some time. The patent was filed September 7th, 1951, a full year before its official introduction. The method of operation remained unchanged, with the two-panel tailgate ram still employed. However, the hinged charge door was eliminated, and replaced with a solid ram panel. Toggle linkage allowed the packing cylinders to swing the ram door up under power, opening the hopper for loading. A slightly larger and wider hopper also helped improve loading access for the crew. The internal retaining panel was now also hydraulically powered by a single hydraulic cylinder, which automatically opened and closed the retainer panel in synchronization with the ram door.

The LP-200 was the first Gar Wood refuse truck to use numerical series designation. The "LP" was for Load-Packer, and the basic series was "200". The last two digits of the series number denoted body capacity, which was initially available in 10, 13 or 16-cubic yards. Thus, a 13-cubic yard model would be designated "LP-213". This numbering system would remain in place for all future Gar Wood refuse equipment. Also new was the practice of pairing all Load-Packer bodies with the appropriate underbody hoist, eliminating the need for customers to choose both a body and hoist when ordering. The LP-200 was a product of the Gar Wood Wayne Division, where all Detroit-area manufacturing was now consolidated.

INSIDE THE LP-200

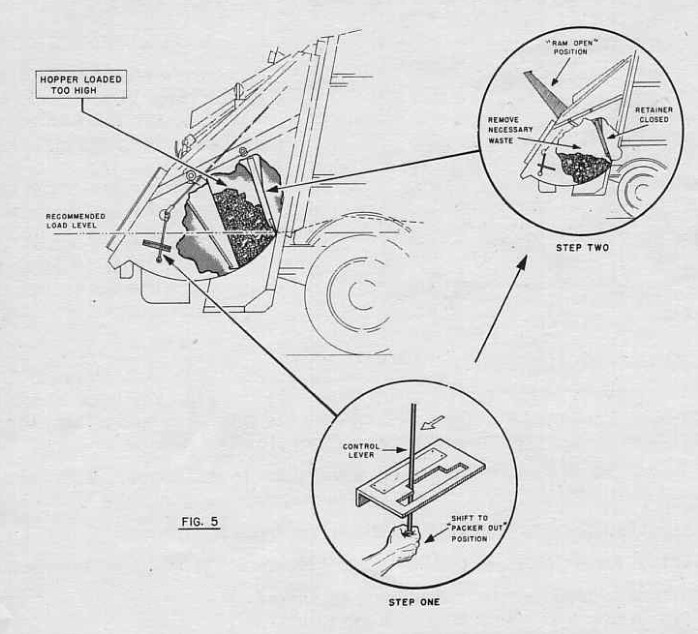

Cycle commences with crewman moving control lever, which causes ram door to "float" down to the closed position. The weight of the door causes it to fall by gravity, while fluid restrictors in the hydraulic cylinders prevent it from falling too fast. The ram door could be stopped at any point in its descent by hand, without risk of injury to crewmen.

|

Crewman continues to hold lever as the lowered ram door closes off the hopper. Its toggle links lock-in, ready for full-power operation. Inside the tailgate, the retaining panel opens hydraulically to a position resting against the back of the ram door.

|

Next, twin 6" hydraulic cylinders are energized (7" cylinders on the LP-216), and full power is applied to the ram door. Ram door sweeps hopper while also pushing in the retaining panel, which scrapes the ram door clean. From this point, the pack cycle is fully automatic, and crewman can go on to next stop.

|

Once the hopper is swept, the retaining panel cylinder is pressurized, holding the compacted refuse within the body. The ram door reverses direction, back to the hopper sill. Here, the links unlock and the ram door is raised hydraulically to the open position, ready for the next charge of refuse.

|

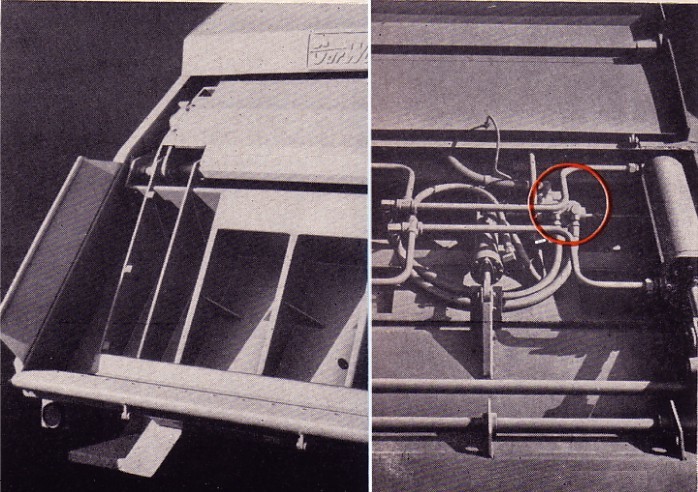

Left: Ram door with outer skin removed, showing massive reinforcing members

Right: Tailgate plumbing and retaining panel with single, center-mounted hydraulic cylinder

LP-200 lubrication points

If the hopper was overloaded, refuse would jam between the ram door and retainer panel. This automatically stopped the cycle, and required the operator to reverse the cycle and remove or level-off excess material.

|

Though no sales figures are available, the LP-200 series was undoubtedly a success for Gar Wood, despite a relatively short production run of approximately six years. A 20-cubic yard version of the LP-200 was added by 1954, joining the Jumbo LP-320 and LP-324 models, which had been introduced the previous year, and are covered in the next chapter. The 24-yard bodies were the largest rear-load packers on the market, yet another Gar Wood "first".

Though no sales figures are available, the LP-200 series was undoubtedly a success for Gar Wood, despite a relatively short production run of approximately six years. A 20-cubic yard version of the LP-200 was added by 1954, joining the Jumbo LP-320 and LP-324 models, which had been introduced the previous year, and are covered in the next chapter. The 24-yard bodies were the largest rear-load packers on the market, yet another Gar Wood "first".

Late 1954 saw yet another milestone, when the City of Key West, Florida purchased five 13-yard Load-Packers. They became the 2,500th American city or contractor use Gar Wood refuse equipment, serving an astonishing 39 million citizens. This was in addition to untold numbers of other customers around the globe. Gar Wood remained the premier refuse body manufacturer at the dawn of the 1950s.

However, Gar Wood was now competing in an increasingly crowded field of refuse packers. Leach and Heil models, arguably superior to the Load-Packer in many ways, would win over more and more customers every year. Better side-load packer bodies were also on the market, and front-loaders were beginning their domination of California and the west. In spite of its improvements, The LP-200 was still based on a now-antiquated 1930s design. When Leach introduced a wheeled container system for their new Packmaster in 1955, it must have been clear that the LP-200 was finished, since its swinging ram door packer design could never be easily adapted to such systems. Gar Wood would no longer be able to survive on past glory alone. Fortunately, their extensive distributor network did an admirable job selling the LP-200 until help arrived for 1957.

GAR WOOD LP-200 GALLERY

City of Indianapolis, Indiana: LP-216 on White 3000 cabover

Ironwood, Michigan: LP-213 on GMC chassis

City of Chicago, Illinois: LP-216 with special International Harvester R-212 cab & chassis

City of Miami Beach, Florida: LP-216

New York City Parks Department: LP-216 on a Walter Snow Fighter for refuse removal from beaches

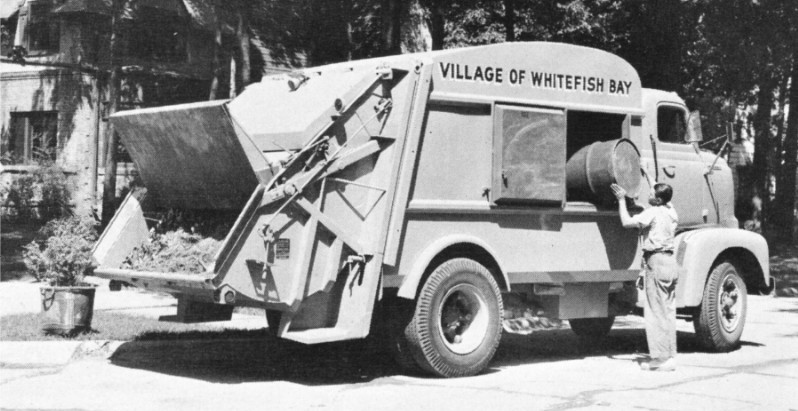

Village of Whitefish Bay, Wisconsin: LP-216

City of Springfield, Illinois: LP-216 on Diamond T chassis

City of Portland, Maine: LP-216

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2733820 |

Refuse Truck |

Starr |

Gar Wood |

September 7, 1951 |

7/30/14

© 2014

All rights reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |