Chapter 7

Load-Packer 300 Series

and LP-220

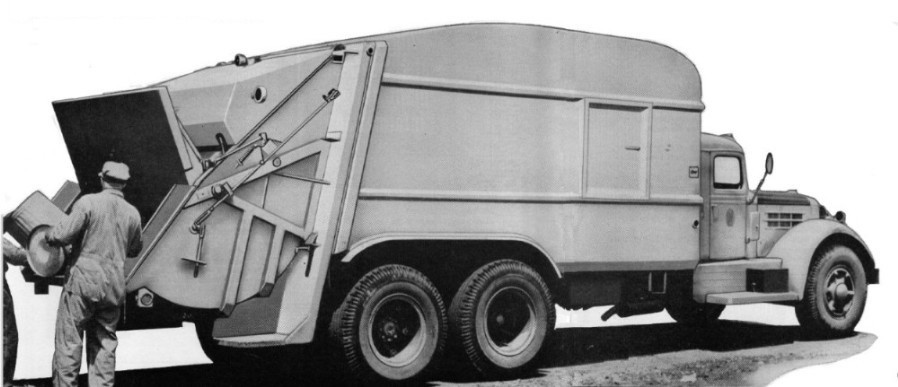

1954 Gar Wood LP-324 was the worlds largest rear loader, with 24-cubic yard capacity

Shortly after the introduction of the new LP-200 series in 10, 13 and 16-cubic yard capacities, Gar Wood announced three new super-sized refuse packers with 20 and 24-cubic yard bodies. These new models were first shown at the APWA Congress in Atlantic City, New Jersey in September of 1954. Model LP-220 was merely an enlarged version of the LP-216, for customers seeking a larger volume body. Up until this point in time, larger bodies were seen as somewhat impractical in a rear-load packer. They could carry more refuse, but the packing mechanism could not deliver consistent densities as well as in the typical 16-yard (or smaller) bodies. Only after the body filled did any compression take place, with the packer working against the entire load within the body. Tilting the body at the dumpsite was often perilous with even the smaller bodies, and the risk of capsizing increased proportionally as body weight and size increased.

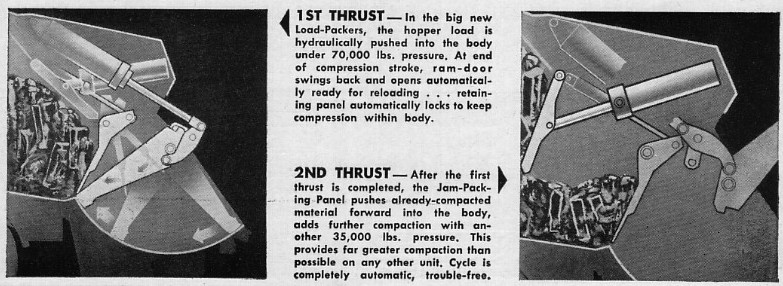

The LP-300 series addressed the issue of compaction density with the addition of a third hydraulic-powered "jam-packing" panel, located high in the tailgate, which automatically forced refuse forward into the body, both compressing the load and keeping the tailgate area cleared for incoming loads. Coupled with larger 7" diameter ram cylinders (as had been used on the LP-216), this helped achieve better payloads in the larger 20 or 24-cubic yard bodies, the latter being the largest rear-loading refuse packer available at that time. The problem of tipping stability remained intractable, for the time being, and would only be overcome by the use of ejection discharge in the future.

INSIDE THE LP-300

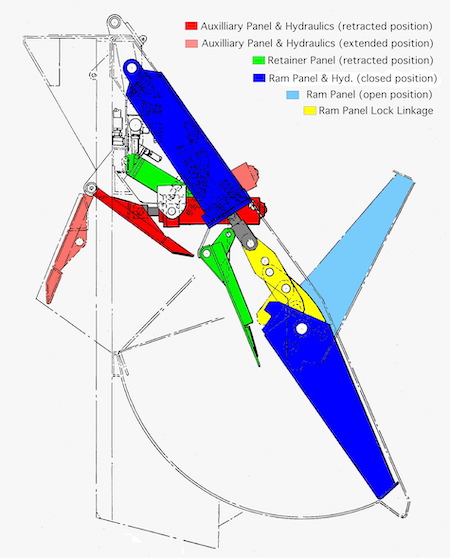

US patent number 2813641 describes the "triple compaction" LP-300. Note that the ram door and retainer panel are identical to the LP-200 (shaded green and blue). The addition of an auxiliary packer panel or "jam-packing" panel (shaded in red), was designed to thrust forward during each cycle, increasing compaction and keeping the passageway between the hopper and main body clear.

As can be seen, the Jam-packing panel actually forms part of the passageway when in the retracted position, with refuse from the hopper forced beneath it. When extended, it shoves the refuse forward into the body.

|

Although considered a separate series, the LP-300 was basically identical to the 200 series except for the jam-packing panel. Outwardly, the models were difficult to distinguish from each other. The most visible feature of the 300 series was a much taller hood covering the upper tailgate, which accommodated the additional hydraulic cylinders and associated linkage for the third panel. The big LP-324 was 17" longer, and 9" taller than the either of the 20-yard boxes.

This LP-320, mounted on a Ford F-series tandem chassis, was owned by the City of Detroit, Department of Parks and Recreation.

It was part of a fleet of nearly 500 Gar Wood Load-Packers in use by that city in 1956.

Compaction specifications in pounds-per-cubic yard had not yet become standard, but Gar Wood claimed that the LP-320 with jam-packing panel provided a 25% increase in payload compared to the LP-220. The LP-324, with its larger body was said to carry 35% more. However, demand for the big bodies was still limited, and it is likely that comparatively few of the 300 series were ever built. When a replacement Load-Packer series was announced in 1957, the 24-yard bodies were eliminated.

The reason for the introduction of these bodies may have had more to do with one-upmanship, as Gar Wood was now locked in a sales battle with Leach and Heil, who had fresh new designs on the market as well. Smaller companies, including Roto-Pac, Pak-Mor and E-Z Pack were also vying for their share of sales. Whether practical or not, having the biggest rear loader in the industry would at least have provided some bragging rights for Gar Wood. Of course, Leach countered by simply enlarging their Packmaster to 25-cubic yards, and it would also be offered with a bulk container hoist system which opened up a whole new commercial market for the rear loader.

Thus, the LP-300 would be short-lived, and was to be the last variation of the original Load-Packer, which first appeared back in 1937. They had always been somewhat complex machines, and became even more so with each modification. The mechanism required many adjustments, and the bulky ram door setup was really beginning to look dated when compared to the competition. The strength of the Gar Wood reputation and their massive sales organization helped insure that the 200/300 series sold very well, but the design had run its course and was officially discontinued by 1958. While it is possible that some models were produced past that time, they did not appear in sales catalogs and were not advertised.

However, before the next generation of Load-Packers would arrive, there would be yet one more interesting rear loader to emerge from Wayne Division, a Gar Wood unlike anything they had ever produced.

City of Detroit, Michigan: LP-220 on tandem-axle GMC

20-yard model on a White 3000 tilt-cab has demonstrator-type markings on the body

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2813641 |

Auxiliary Compressing Panel for Refuse Trucks |

Starr |

Gar Wood |

December 6, 1955 |

7/30/14

© 2014

All rights reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

| |