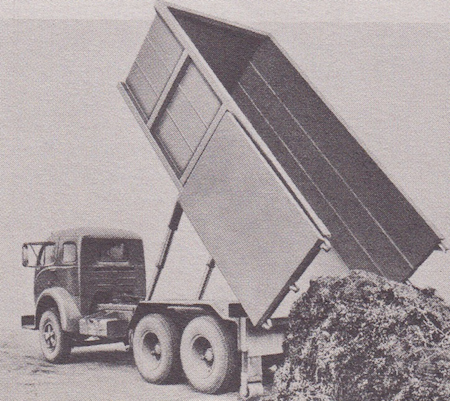

Huge Haul

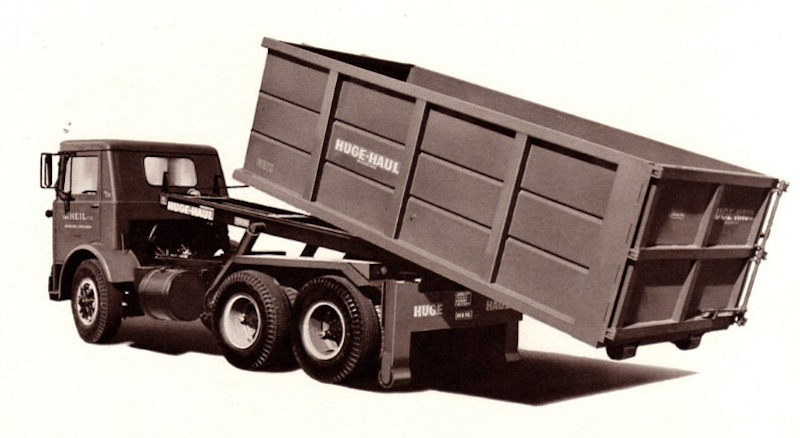

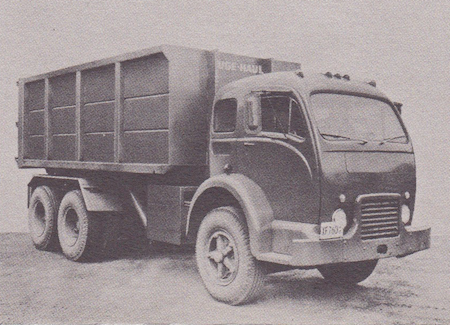

Heil Huge-Haul HH-30 (30,000 lbs. lift capacity) on Mack MB chassis

The Huge-Haul roll-off, which came with the purchase of Load-Lugger in 1961, was another timely addition to the Heil product line. These types of detachable container trucks would soon be the mainstay of the construction/demolition trades, and (when coupled with stationary packer units) the next big trend in bulk storage and hauling of commercial refuse. Like Load-Lugger, this product would compete mainly competed with Dempster and a handful of independent firms. Leach and Gar Wood, then Heil's chief rivals in the rear loader field, had no competitive units available. The Huge-Haul roll-off used a twin-cylinder hydraulic reeving hoist, of the type that has since become universal on roll-offs today, and could handle containers up to 40-cubic yards. Unlike most modern roll-offs, Huge-Haul was a "dead lift" type hoist, which first lifted the container up to frame level before dragging it on to the tilting frame rails.

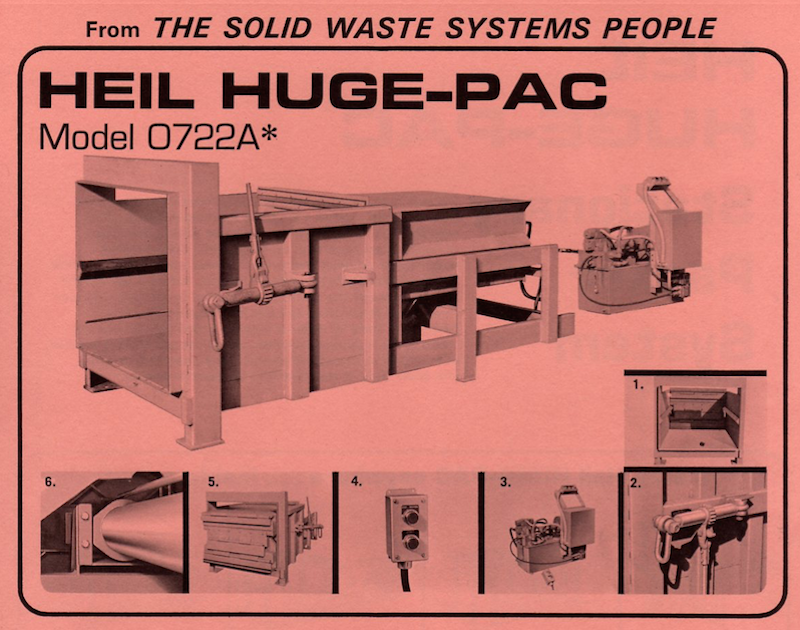

Stationary packers were added in 1964, when Heil became national distributors for the O'Connor product line, for both the Huge-Haul and Load-Lugger models. O'Conner stationary packers were sold by Heil distributors, and by 1967 were being marketed under the Huge-Pac trade name. During the 1970s, they were badged as Haul-Pac containers. By the late 1970s, Load-Lugger/Huge-Haul was the last refuse equipment line built at Heil's Milwaukee factory. When Heil finally sold off the division in 1984, the new owners changed the trade name to Huge-Haul Inc., to reflect the dominance achieved by the roll-off during the intervening decades. The independent Huge-Haul Inc. remained in Milwaukee until being bought by Benlee in 2016, at which time operations moved back to Michigan for the first time since 1961.

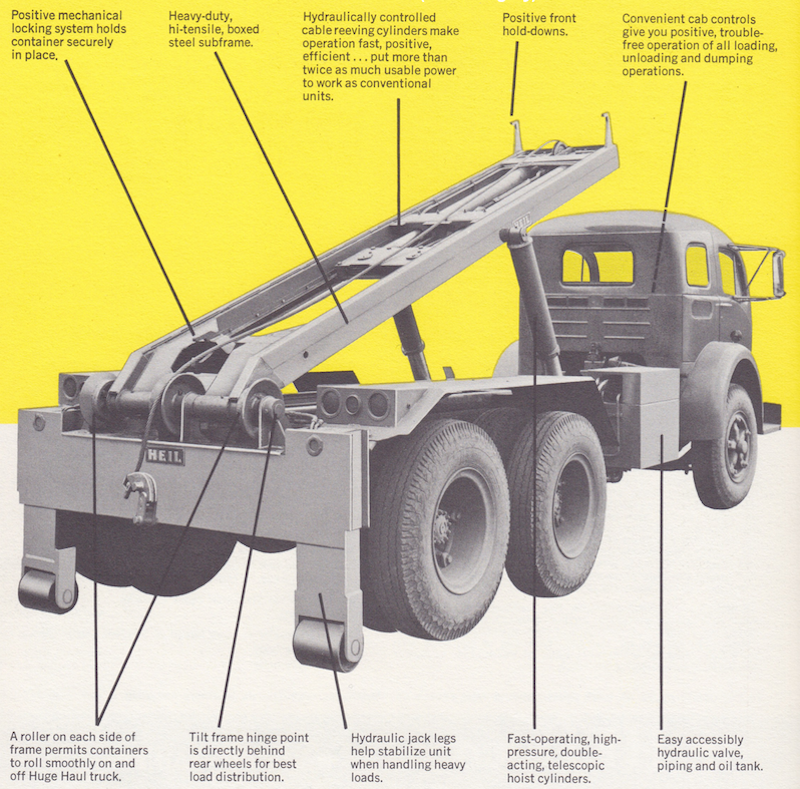

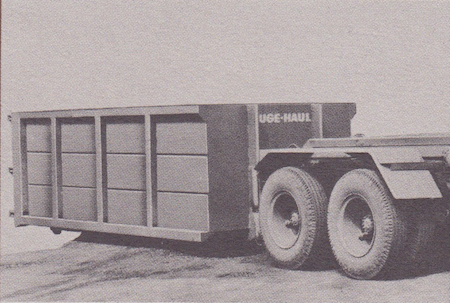

Features of the Heil Huge-Haul roll-off

Heil Huge-Haul on a Mack DM800 chassis

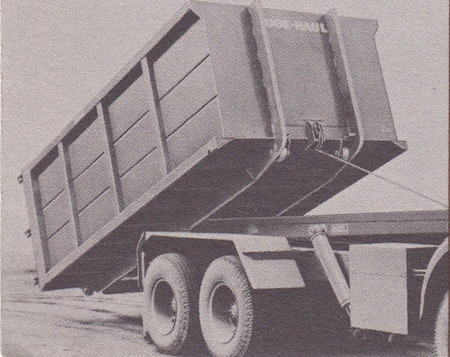

In addition to transporting containers, Huge-Haul could also serve as a conventional dump truck

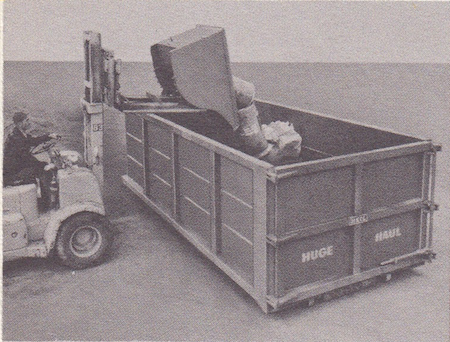

Huge-Pac was a stationary packer unit left on-site, which filled containers, which were then removed and replaced by a Huge-Haul roll-off

Container is loaded at site by customer, either from overhead or through rear door. When filled, it is ready for pickup by Huge Haul. Another container may be delivered to replace it as needed.

|

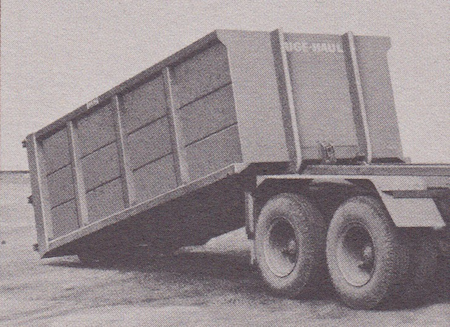

Truck backs up to container, and lift cable is attached with hook and latch. Container is self-aligning, even at wide angles.

|

Container is lifted up and on to tilt frame trails by powerful twin-cylinder reeving hoist, controlled by operator in cab.

|

Container rides aboard rails on two large, tapered rollers located at the rear of the tilt frame. Hydraulic jacklegs at rear of vehicle may be lowered when lifting heavy loads.

|

Container is now loaded on vehicle, held securely by positive mechanical locks. Total average loading time is 60 seconds, and can be off-loaded in 75 seconds with only one man.

|

The filled container is unloaded by tilting the frame with rear door opened, like a conventional dump truck. A pair of double-acting, 3-stage telescopic cylinders are located underneath and outboard of tilt frame. Alternately, the filled container could also be dropped off at a central yard for later disposal.

|

5/29/17

© 2017

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

| |