Hydepak and Hobbs Hyd-Pak

Fort Worth and Cleburne, Texas

The first Hydepak Side Loader design was patented by James Huffines of Wichita Falls, Texas in late 1953. The first commercially available versions were dubbed "Hydepak", evidently named after Edd Hyde, who had built the body. These first appeared around 1954-55, and were constructed at a facility in Cleburne, Texas. With the body mounted on top of a standard truck chassis, it was comparable with contemporary side load packers such as Pak-Mor, Marion and MB. Where the Hydepak differed was in its partial-packing cycle. Most competing side loader designs favored a plate that travelled the entire length of the body, while the Hydepak packer plate travelled only enough to clear refuse from the hopper area between the truck cab and the body. Compaction occurred after the body became filled, with the packer plate force then being applied to the entire load. Among U.S. side loaders, this principle had previously found little acceptance. That would eventually change, and the Hydepak may be credited as being one of the earliest successful examples using the partial-packer method. They would be followed by many others in future, particularly Southern California manufacturers who adapted it for use in front loaders and drop-frame side loaders.

The Hydepak is also one of the first side loaders to apply direct hydraulic power to the packer plate, rather than using a winch or helical screw drive. A double-acting hydraulic cylinder, mounted under the truck body operated the packer plate. Its rod end was connected to the bottom of the plate through a slot in the hopper floor. Since the packer plate did not travel the length of the body, a common short-stroke, single stage cylinder could be used. The result was a relatively inexpensive design offering good compaction, though the partial-pack design necessitated hoist dumping at the disposal point. This was done in the conventional manner by twin underbody hydraulic rams. The passage leading from the hopper area to the body was restricted by a pivoting panel, which acted as a load retainer to keep refuse from falling back after each cycle. The panel could tilt inward toward the body if any refuse came between it and the packing panel.

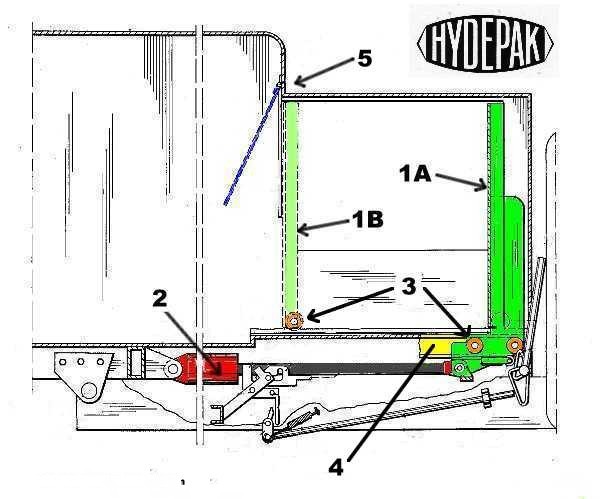

Hydepak cut-away drawing, shortened for clarity (note broken lines through body)

The packing panel (green highlights) shown in retracted, load receiving position at (1A) and extended packing position at (1B) was powered by single stage, double acting ram (2) located under the floor. Upper and lower rollers (3) followed angle-iron trackways (4) to stabilize the blade, while hinged panel (5) helped to retain previously compacted material within the body.

Early on, the Hydepak was distributed by Triad Sales Corporation of Dallas, but by 1956 they were trading as the Hyde Corporation with a Fort Worth mailing address. In 1958, Edd Hyde sold the company to Hobbs Trailer, thereafter becoming the Hydepak Division. The manufacturing facility at Cleburne was retained.

It is interesting to note that Hobbs Trailer was itself owned by the giant trailer maker Fruehauf. Executive vice president (and former Hobbs general manager) of Fruehauf at the time was one William E. Grace, who is believed to be the same individual who owned the W.E. Grace Company of Dallas. W.E. Grace had developed one of the first side load packer trucks in the early 1940s. William Grace's past involvement in the Texas refuse truck industry may have figured in the decision by Hobbs to acquire Hydepack. The new owners would greatly expand the product line beyond the basic Hydepak side loader, into a broad range of refuse hauling equipment.

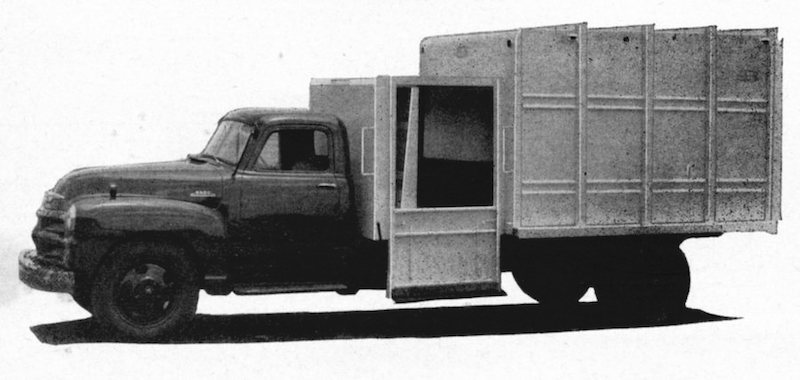

1956 Hydepak owned by Jacksonville Beach, Florida

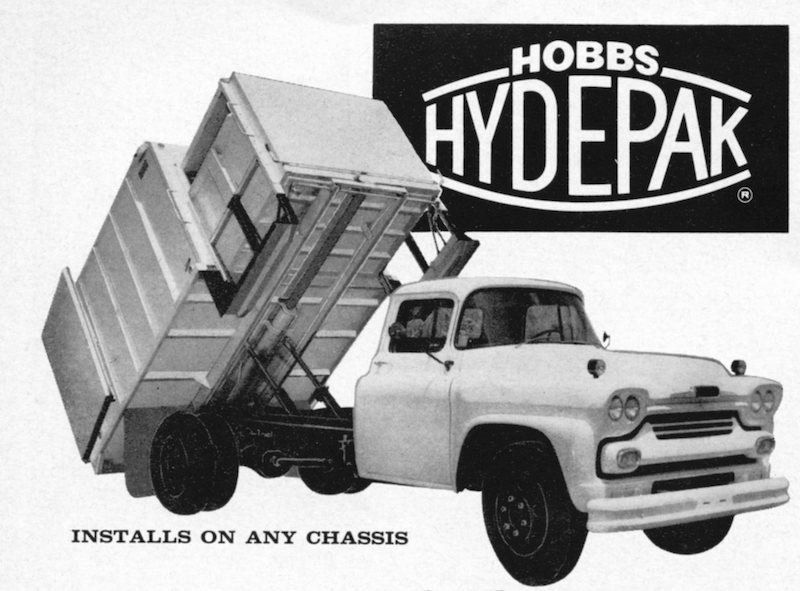

1958 Hydepak shown in the unloading position. Note the packer cylinder visible underneath the raised body.

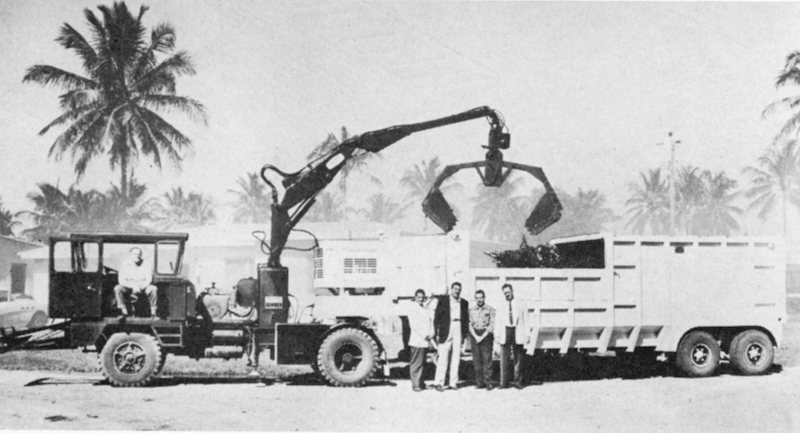

Being wholly a wholly-owned subsidiary of world-renowned trailer manufacturer, it should come as no surprise that one of their first new Hydepak products introduced was a large compaction trailer, the Trailer-Pak, which arrived about 1960. It could be ordered as a top loader for use as a transfer-station relay vehicle, or as a side loader for residential pick up. Low loading height of 38" above ground was achieved by the drop-frame construction of the trailer. The compaction/ejection ram, a full-travel telescopic cylinder, was concealed in the A-frame of the trailer tongue.

A 35 cubic yard Trailer-Pak handles palm fronds with ease in Dade County, Florida. Note the auxiliary engine for the

packer mounted on the trailer tongue. A Daybrook loader arm does the lifting.

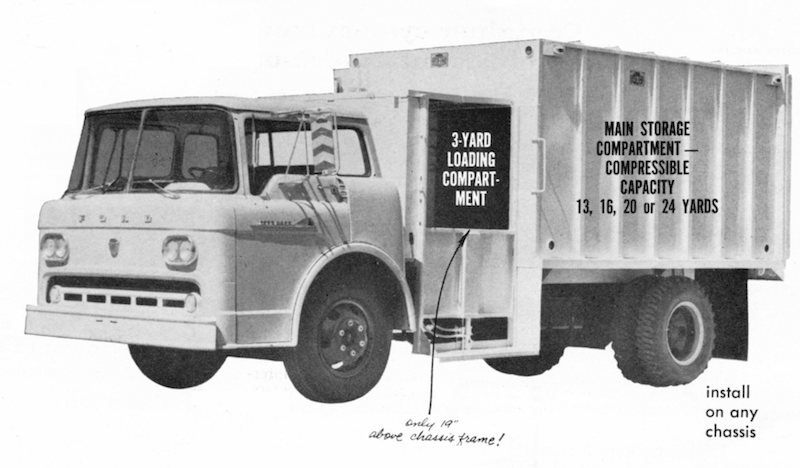

The original Hydepak side loader remained basically the same, become the 60-Series for the 1960 model year. The packing cylinder was relocated inside the body (above the floor), thereby eliminating the leaky slot on the hopper floor. During this time, the competitive mechanical packers on the market, notably Pak-Mor, Seal-Press and MB, had begun the switch to full-hydraulic power in one form or another. Accordingly, Hobbs' refuse equipment underwent a name change, becoming Hyd-Pak instead of Hydepak, probably to emphasize the "all hydraulic" features long associated with their line. A hydraulic container lift attachment also became optional for handling 1-3 yard capacity wheeled cans.

60-Series side loader; Hobbs emphasized its light weight and spacious hopper

The new container handling system for the Hyd-Pak side loader

60-Series on a maneuverable GMC steel tilt cab chassis

Riverside, California employed this White Compact series tractor with a 42-yard Hyd-Pak trailer to service 4-yard containers

HYD-PAK M-SERIES SIDE LOADER

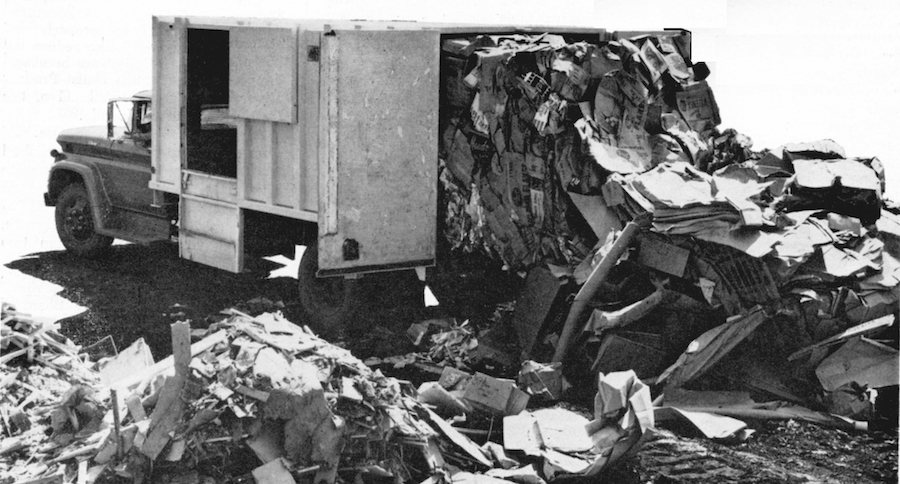

By 1962, the side loader packer field was becoming crowded. Both Baughman (Jerseyville, Illinois) and Theile (Somerset, Pennsylvania) were building near-identical copies of the original Hyd-Pak 60-Series side loader. In Los Angeles, Western Body and Bowles were both building an improved variation of the partial-pack side loader with their respective Shu-Pak and Load-N-Pack drop-frame units. Hobbs answer to the increased competition was to diversify the lineup with the new Hyd-Pak M-Series, a full-height, full-travel packer with a horizontally-mounted telescopic ram. With the M-Series side loader, Hobbs had a good starting base for a front loader, but evidently decided not to compete in that segment of the market.

M-Series mounted on a 1963 GMC chassis

M-Series side loader hauls box-car refuse for the Santa Fe railroad

Ejecting a high-density load of cardboard

PACK-SADDLE ROLL-OFF

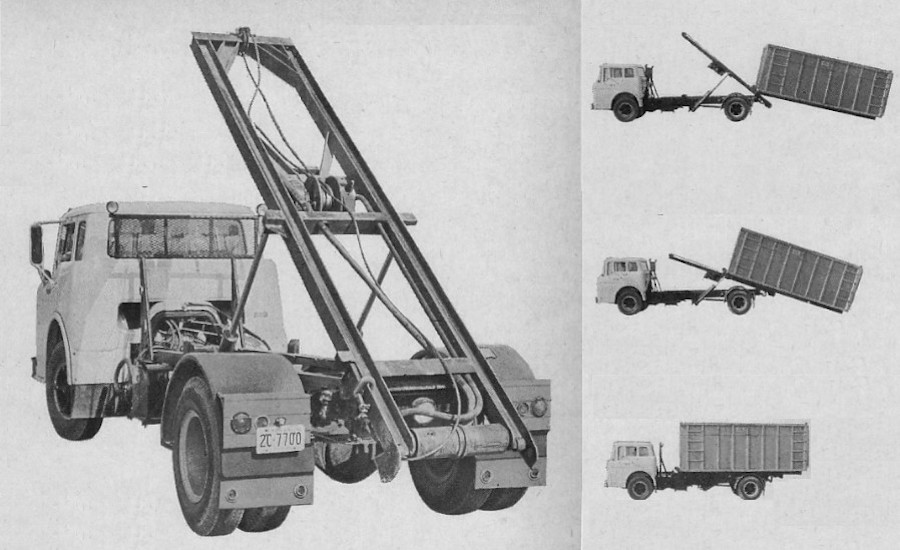

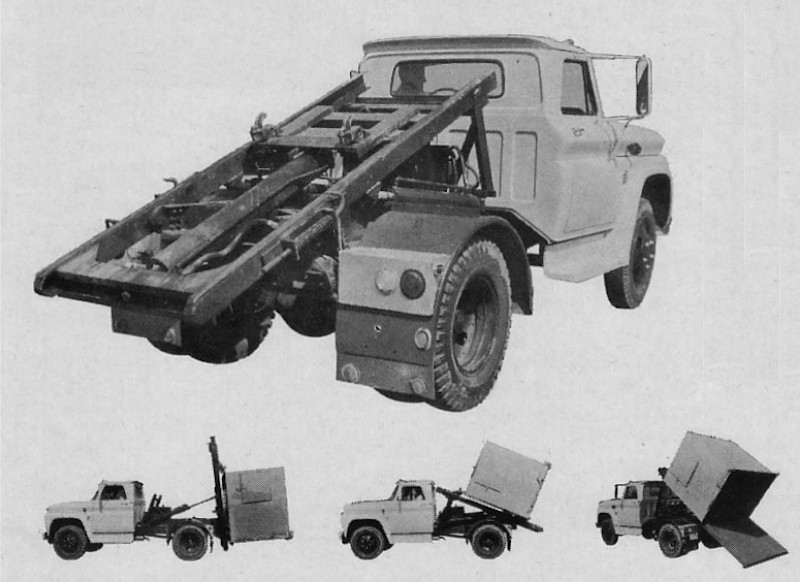

Hyd-pak was also aggressive in going after the bulk refuse handling market, developing the Pack-Saddle cable roll-off container truck and a single container carrier called the Papoose which was designed to compete with Dempster's short-haul Dumpster system. By 1965, they had also joined the list of truck manufacturers offering refuse transfer stations to compliment their trailer line.

The Pack-Saddle, a winch-operated roll-off

The Papoose bottom-dumping, short-haul container system

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2750055 |

Refuse compressor mechanism for vehicles |

Huffines |

|

December 24, 1953 |

|

US2996203 |

Packer type refuse truck |

Rosaia |

|

September 22, 1958 |

|

US3142397 |

Cable operated vehicle loader |

Felts |

Fruehauf Corp. |

June 13, 1962 |

|

US3175708 |

Support for hydraulic cylinder |

Felts |

Fruehauf Corp. |

January 10, 1963 |

|

US3269572 |

Vehicle loader |

Felts |

Fruehauf Corp. |

August 30, 1966 |

3/5/06 (revised 11/28/21)

© 2006

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

|

|

| |