Early Load-Master: Recollections and Impressions

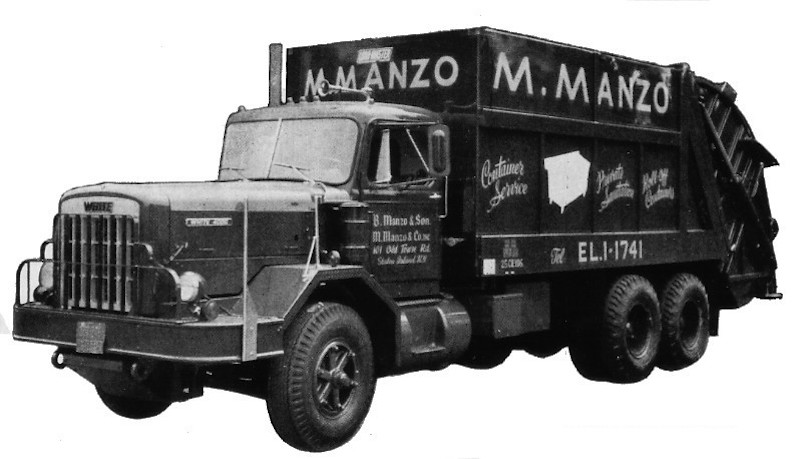

1970 Load-Master LM-125 on heavy-duty White Construcktor owned by M. Manzo & Co., Staten Island, New York

After only five years on the market, the Load-Master was already establishing a solid sales record. This advanced refuse body from a small eastern manufacturer was the first true competitor of the Leach 2-R Packmaster, while the rest of the industry was left to play catch-up. While the Load-Master clearly borrowed technology from the Leach (as did all slide-sweep designs born in the wake of the 2-R), it differed at least enough that it was not merely a copy. Despite this, patent information on the Load-Master design prior to 1970 has proven to be elusive. The only Load-Master patents currently known were all filed years after its introduction.

John Thomas is a man who has many years experience in the refuse body industry, including time at City Tank Corporation in the 1960s, recalls the atmosphere at the company which may explain the lack of patent documentation:

"Mel Stewart, the sales manager at Loadmaster, was very non-traditional in his approach to reaching the marketplace. He almost never advertised, and did not exhibit at the two major trade shows (NSWMA & AARP). I worked for Mel at City Tank when we were introducing the Loadmaster. I can't recall the engineer's name, but I do recall that the whole engineering effort was quite informal in Culpeper, Virginia. I would be a bit surprised if City Tank ever applied for a patent."

Regular CRT contributor Dana Gregory also has firsthand experience with the early Load-Master models, and recalls:

"The 100 was a very popular body in the Boston area in the mid 1960s to the 1970s. Many contractors got their start with one or two Loadmaster 100's. I remember in the early seventies that you could buy a new Diamond Reo with a Cummins diesel engine, 5-speed transmission, 2-speed rear axle, and a Loadmaster 100 with container hoist for about $22,000. It was reasonably priced and was economical to operate. The hydraulics were dependable and almost never leaked. It handled bulk and up to 10 yard containers."

"It became the number one choice for municipalities doing their own collections. Its drawback was the payload: an average load of residential trash was about 600 pounds per cubic yard. In the mid to late sixties, even into the early seventies, a six ton load on a 20-yard was pretty good. However, as unlimited collection became more popular in municipal contracts, the only body that could handle the job was the Leach 2R. In metro Boston, it was the king. "

A model LM-320 from the 1970's

Dana also recalls how the smaller LM-300 series fared in the Boston area:

"[The LM-300] was a nice working body, and a very worthy competitor to the Leach Standard Packmaster and the Gar Wood LP-700. In my opinion, it was actually superior in that it handled bulk, and packed a surprisingly good load. Average payload on a 20 yard with residential trash was seven tons. That's right, seven tons! Those who used this unit were all surprised at the load, as no one expected 700 lbs/yd. The Leach Packmaster Pushout would just barely get six tons and was very slow. The Gar Wood, though much faster, would only average 600 lbs/yd. The LM-300 became popular with municipalities, especially New York City. They bought a large number of them in the 1970's. Not a bad body, and it would handle containers as well."

FROM THE AUTHOR: MEMORIES OF BIG RED

Pictured below is "Big Red", a 1969 Load-Master LM-320T on a 1981 International owned by L.R. Stuart Refuse Removal of Manassas, Virginia. This was the first truck I drove when I worked for the Stuarts in 1986. The Load-Master body was at that time riding on its third truck chassis and had been in daily service for almost eighteen years.

Load-Master had a very strong following in the National Capitol Area, which was only natural since it was a short hop up U.S. 29 from Culpeper to Washington. The counties of Fairfax, and Arlington as well as the City of Falls Church and Town of Vienna were among the local municipalities that operated them in their fleets. I grew up around Big Red, having witnessed the truck's inauguration in 1969, and when I was a little older even worked two or three days a week during the Summer of 1974. As I recall, the pay was $5.00 per day, a tidy sum for a ten year-old boy at that time. Mr. Stuart was generous, especially since he was surely aware that I would have paid him to work on that truck! After at ten year hiatus, I went to work full-time for Stuart in 1986, and was somewhat surprised to find that Big Red was still around.

Most of the small haulers in my area didn't own a Leach 2-R or anything that powerful. The Virginia-built Load-Master and Truxmore barrel packers seemed to be predominant. The amazing thing is that Stuart treated Big Red as if it was a 2-R; this Load-Master devoured all manner of furniture, crates, furnaces and air conditioners, water heaters, piano sound boards and even a pickup truck bed during its long working life. Handling mostly suburban residential routes, this packer never had a proper container lift. However, L.R. had a set of chains welded to the sweep panel so it could at least empty small containers in the same manner as a Leach Standard Packmaster. This was not an approved option, but it worked just the same. Overall, the packer was a simple and reliable machine, and hardly ever experienced major downtime.

After a few years as the lone truck, a second-hand 1966 International Loadstar equipped with a Gar Wood LP-720 was purchased from Fitzhugh's Sanitation, joining Big Red sometime around 1972. The Gar Wood was fast, and packed household refuse quite well, but it couldn't compete with the Load-Master's crushing power. The Gar Wood crew had to leave behind most bulky objects, which were then collected later by Big Red. The Gar Wood proved to be less reliable, suffering somewhat frequent breakdowns of the conveyor panel chain drive, although to be fair it was by that time already well-worn. Additionally, the Gar Wood was operating with only one of two conveyor panel hooks, and when the other one finally broke off, the conveyor would no longer lock in level as the packer blade swept over it. As L.R. later recounted to me, he was so fed-up with the trouble-prone Gar Wood that he finished what he could of the route by hand-loading through the side door of the body. Then, after unloading at the landfill, he promptly drove the stricken packer to Wilbar Equipment in Springfield, Virginia to have a brand-new Load-Master LM-320 body installed. Stuart's thus became a two-Load-Master company for the next ten years or so.

Big Red was built at time when safety standards were virtually non-existent. Pulling the control handle out and back started the fully automatic packing cycle without interruption. That is to say, the panels did not stop before reaching the loading sill, as is standard on modern packers. In light of this fact, it was doubly imperative that you stood clear of the hopper as the blade approached the 'pinch point'. In later years when I was assigned this truck, I actually found this feature to be quite convenient, especially on days when I had no helper. The automatic cycle allowed me to keep moving and keep loading, thus wasting less time manipulating the packer control. As long as one simply exercised good judgment and common sense, it wasn't really dangerous at all.

Perhaps the best feature of Big Red was built in to the main hydraulic control valve for the packer. As mentioned, the cycle was fully automatic by way of pilot-operated circuitry, but also featured what we loosely termed the "ride up"' valve. Here's how it worked: when the body was full or the ejector needed to be moved to make room, the packing cylinders would naturally meet with increased resistance. This would cause a spike in hydraulic pressure, which would otherwise cause the spool valve to trip and stop the packer before the cycle was complete. What Load-Master apparently had done was to arrange the plumbing in the main control valve so that this pressure spike opened a circuit that bled pressure off the sweep cylinders, thus allowing the sweep panel to open slightly and 'ride up' over trash (as needed) while the packer cylinders extended towards the 'home' position. It worked flawlessly, allowing the packer to complete the full cycle without stopping regardless overload conditions. By contrast, our other later model LM-300 had the modern split cycle controls, which would simply stop the cycle once the packer encountered resistance beyond the system operating pressure, thus requiring further operator attention.

By the late 1980s, traffic woes and an increased route size dictated the need for a more powerful packer. After eighteen years, three truck chassis, and a few floor and hopper re-linings, Big Red was finally replaced with a Heil Formula 5000. The powerful new Heil packer was a welcome relief, but many of us were sad to see the old Load-Master finally retire. In its day, Big Red had served us so well, and had proven to be a terrific value.

-Eric Voytko

|

7/4/10

© 2010

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|