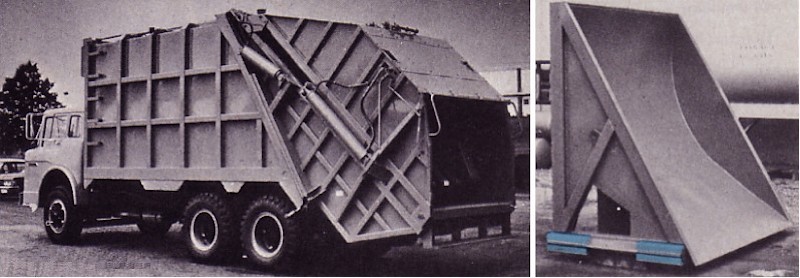

An early model Load-Master LM-425 It is ironic that Leach Company did not apply the 2-R method to their entire product line early on, but instead waited until 1986 before announcing the mid-range Alpha series. During the 1960s, Load-Master could out-perform and out-pack just about everything except the 2-R, and their 600-700 pounds per cubic yard was more than enough for most customers at that time. But by the dawn of the next decade, the 2-R Leach was at last coming of age. It had an established reputation as the world's most powerful rear loader, and was the truck of choice for contractors with the most demanding routes. Amongst New York area haulers, particularly those who specialized in construction/demolition waste, it was becoming the beloved favorite. Its gaping maw was unrivaled in its crushing power. Moreover, municipalities and private fleets were coming to appreciate the 2-R's appetite for household refuse, which it ate at the rate of up to 1,000 pounds per cubic yard. At a time when some tips charged by truck capacity (and not weight), the big 2-R was well worth the extra cost. If the 2-R had perhaps been a case of 'too much, too soon' in 1960, it was 'just right' and in-demand by 1970. So despite the success of the Load-Master, City Tank was without a high-compaction, super heavy duty rear loader to compete with Leach, just as the market was ripening for such a packer. The Load-Master was a solid design to build upon, but its construction needed to be beefed up to withstand the increased pressures needed to deliver the big payloads that would compete with the 2-R. Instead of merely upgrading the existing LM-100, Load-master came out with an all-new series dubbed the LM-400.

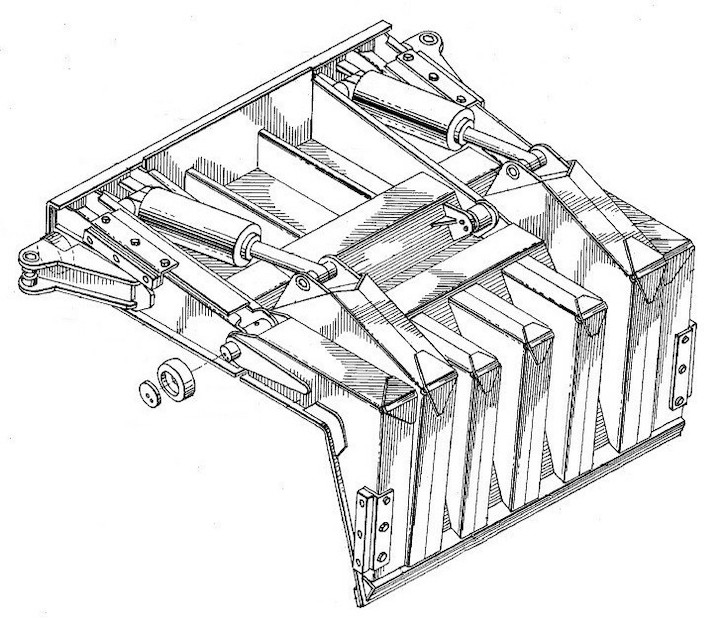

The mighty claw-like packer of the LM-400 looked impressive, with performance to match Massive 7" diameter cylinders operating the sweep panel provided load-crushing power for the new 400, which could demolish the most stubborn bulk objects. Outside the hopper sidewalls, a pair of big 5.5" diameter, 41"-stroke packing cylinders added high-compaction thrust to carry the load into the body. Tailgate lift cylinders, no longer concealed within the structure, were mounted openly on the outside walls. The full compliment of Load-Master container lifts was of course offered, with line pull up to 12,000 pounds.

400 series packer was a beefed-up version of the original Load-Master

Demolition king: circa-1970s Autocar DC with Load-Master LM-425 high-compaction rear loader

400 series curved ejector featured polymer wear blocks (blue highlights) With the original Load-Master's features finally mated with a heavy-duty structure, City Tank now had a rear loader that could match the features of the Leach 2-R Packmaster, pound-for-pound, in every category. On routes that were once strictly Leach territory, Load-Master was now competing, and in the opinion of some, even exceeding the capability of the vaunted 2-R. Dana Gregory had experience with the LM-400, nicknamed "The Iron Monster" in the Boston area: " It was a very worthy competitor to the Leach 2-R. My opinion was that is was actually superior in some ways, especially the ejector blade. Using a four stage telescopic cylinder, it would push out the load in one smooth stroke, with no hang-ups thanks to the curved shape of the ejector blade. I used one in the mid-seventies, the first one used in the Boston area, on residential routes that were unlimited collection. Simply put, what ever was put out for collection had to be taken. That meant everything. The 400 was a beast well suited for this task. Its claw-like packer blade would easily maul and crush bulky items in the hopper before compacting them into the body. It handled ten yard containers as well as the Leach 2-R, and packed just as good a load. Only you didn't have to fight with 2 x 4's and a loose clamping system [the Leach 'Push-Out' system] to push out the load. This body would easily go head-to-head with the 2-R and in some cases, as in New York City, beat it."

"If I were to purchase a rear load packer for commercial/industrial container work, my first choice would be the Loadmaster 400. I wouldn't have to think twice about it. Having operated one, I know what "The Iron Monster" can do."

This beautifully restored LM-425 was one of the first trucks in the Waste Pro Museum 7/4/10 (updated 8/28/21) © 2010 All Rights Reserved Photos from factory brochures/advertisements except as noted Logos shown are the trademarks of respective manufacturers |