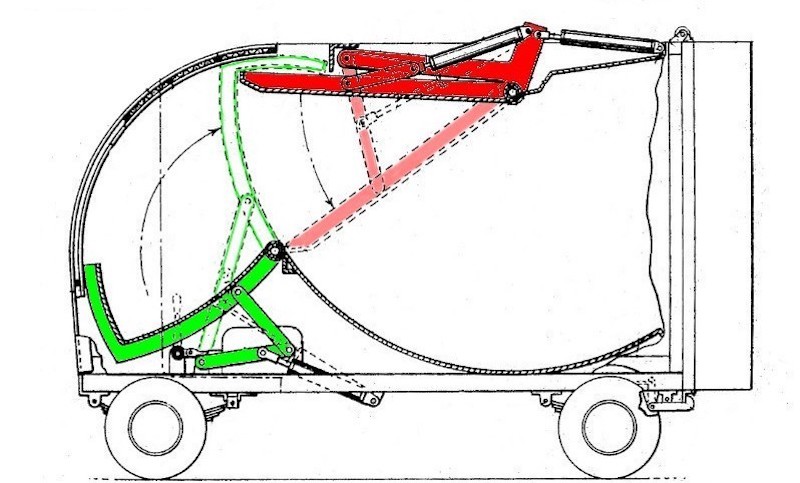

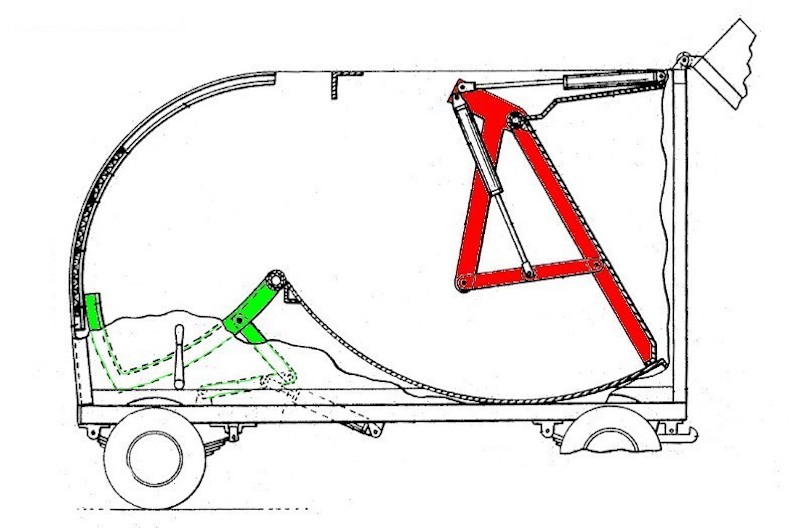

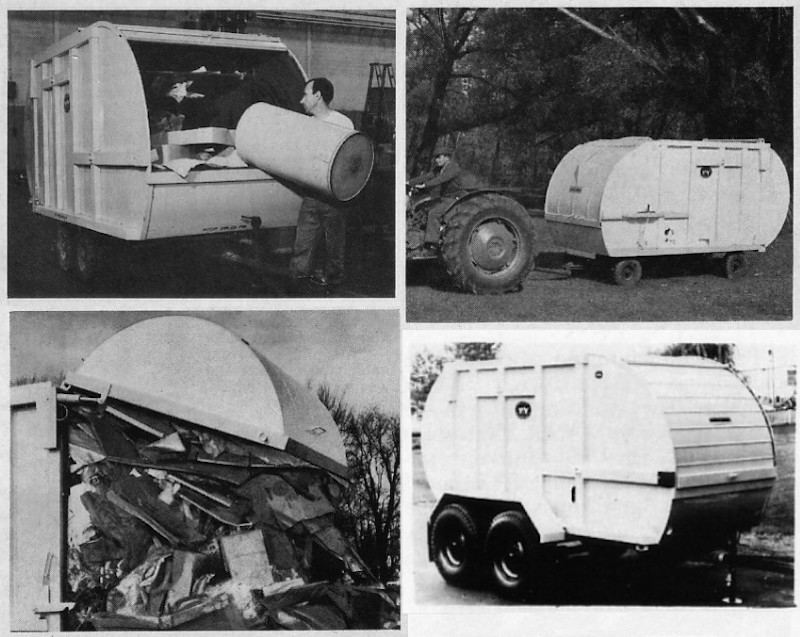

Moto-Pack was ideal for campus collection when coupled with a small tractor Moto-Pack was a mid-1966 addition to the M-B lineup, a five-yard portable compactor suitable for use either as a stationary packer, or as a tow-behind unit for on-site collection. Another creation of James Weir, the Moto-Pack incorporates many of the features of his Pack-King; it was a hinged-hopper, batch-loading packer with a forward hopper and rear discharge. Unlike the Pack-King, the Moto-Pack was loaded directly into the front of the body, rather than through side openings. It featured a much larger packer blade, which not only swept the raised hopper/trough, but also was capable of further movement into the body for full compaction and load ejection. The packer blade was operated via a progressive linkage featuring two sets of hydraulic cylinders. During the initial fill, the packer blade was swung to its uppermost position, near the roof of the unit, which allowed refuse to be loaded through the hopper area and directly into the main body. As the unit filled, the packer plate was activated to crush and retain the loaded refuse. New batches of refuse were added to the hopper. Subsequent cycles then utilized the hinged trough and packer blade working in concert, as on the Pack-King.

Although Moto-Pack was originally introduced to compliment the Pack-King, it became their lone model after M-B had discontinued production of their full-size refuse bodies. Moto-Pack remained in production through the mid-1970s, but it also was eventually dropped. Though no longer making refuse packers, M-B Companies Inc. remains an established manufacturer, and is still located in New Holstein. They produce a variety of industrial equipment that includes airport snow brooms and sweeper attachments, pavement-striping equipment and articulated tractors. SELECTED PATENTS

|