McNeilus

Curved-body Rear Loader

McNeilus curved-shell Standard rear loader

1993 was the breakout year for McNeilus, with the introduction of their first front loader, and an all-new rear loader design that would set new industry standards. Stemming from the SRS semi-round-walled body first shown three years earlier, the new rear loader employed curved-side body construction for a clean and almost pillar-less look. This was only the third attempt in history to introduce a curved-side rear loader in North America; The 1978 Gar Wood LP-10 00 and the 1984 Crane Carrier IRL were the only others. The McNeilus was still essentially box-like, but with gracefully radiused panels, somewhat akin to the front loaders made by Able Body Company, but without any vertical ribs. A heavier superstructure was incorporated at the rear, to support the tailgate hinge, and gradually tapered into the body front. It was (and is) a beautiful design, and made the old braced-box bodies look like dinosaurs almost overnight. It would be the most imitated rear loader body ever produced, as virtually the entire industry changed over to some variation of it during the ensuing years.

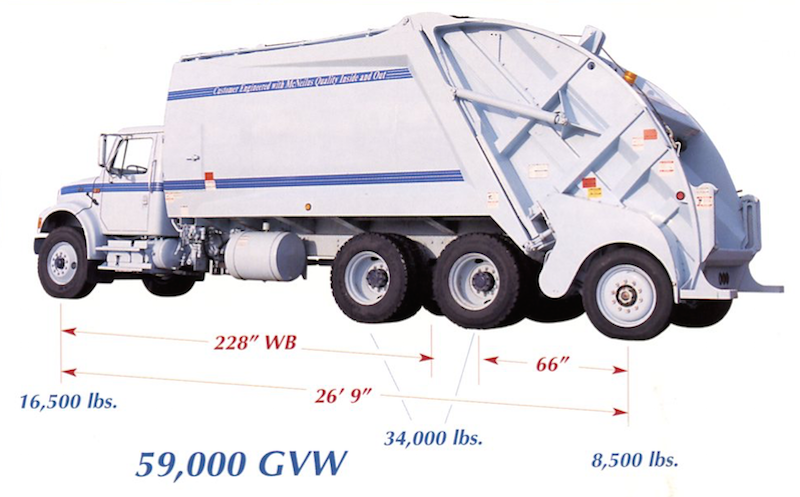

The new McNeilus curved-side models were split into two series. The Standard Series had a 3-cubic yard hopper and body sizes of 17, 20, 25 and 32-yards and rated at up to 800 pounds per cubic yard. The heavy-duty XC Series (Extra Compaction) was available only as a 25 or 32-yarder, with a 3.5-yard bucket and larger cylinders (5.5" sweep/5" slide). The "Big Mac" is as powerful as it is attractive, with estimated loads in the 1,000-1,200 lbs/yd range. Externally, the Standard and XC are almost identical and hard to tell apart. Polymer slide blocks guide the packer, with access panels outside of the track for ease of service.

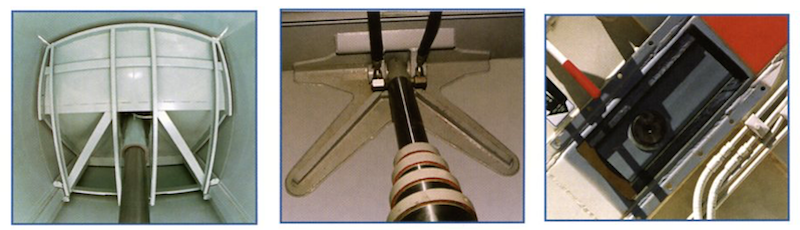

Inside the sleek new body was a completely redesigned ejector with center-mount cylinder, another feature which has become an industry standard. The floor trough was eliminated, and slide blocks were relocated to the body sides. McNeilus hydraulic cylinders, with the Hydro-Cush feature protected against shock loads at the end each stroke. Pack-on-the-go hydraulics were standard, and a host of optional container hoists and accessories were available. A special tag axle version had a slightly narrower hopper to accommodate the air suspension components. The tailgate lift cylinders were attached almost horizontally to increase lift leverage.

The Standard/XC Series put McNeilus on the map, and these rear loaders soon began appearing in the fleets of regional and national hauling companies. With a well-built packer and the most modern body in the industry, its no surprise either. What is surprising is why no other major manufacturer had, up to that point, tried the curved body on rear loader. It had been around for some time, although in relatively low numbers. This may be due to the increased availability of ever-stronger high-strength steel alloys which are needed to build this style body. Perhaps McNeilus' experience in manufacturing concrete mixer drums played some part in their decision to use similar construction on their refuse bodies.

Big Mac: The 32-yard McNeilus XC Series

Angle-mounted ejector ram, reinforced cylinder support, packer slide block access panel

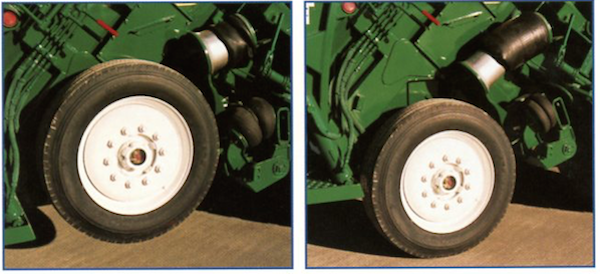

XC Series tag-axle option shifts more weight to the front axle

With fender removed, tag axle air suspension components are revealed

Big 32-yard XC for Interstate Waste Services

Like the earlier Pacstar-RL, the operating cylinders are in the same plane

McNeilus rear loaders have become quite popular in residential collection

9/24/17

© 2017

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

| |