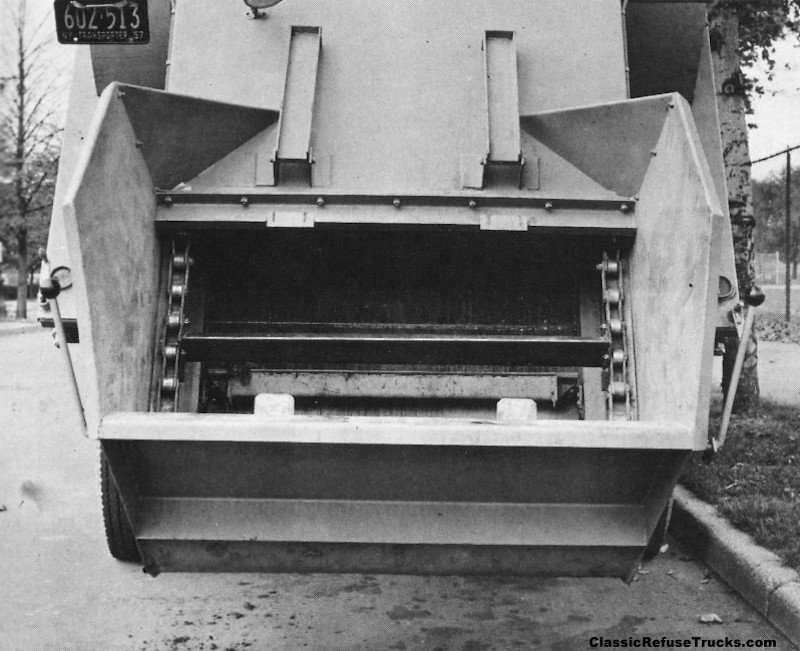

Wide Hopper Version (1957) and Roto-Can System

The last major update to the Roto-Pac occurred in 1957, when the loading hopper was expanded from 36" to 56" width. This change better accommodated loading by two crewmen. Competitive batch-type rear loaders were steadily increasing hopper sizes in the late 1950s, culminating with 1957 Gar Wood LP-500 that boasted a 75" loading sill. Roto-Pac could not match this, but at least stayed in the running with the upgrade.

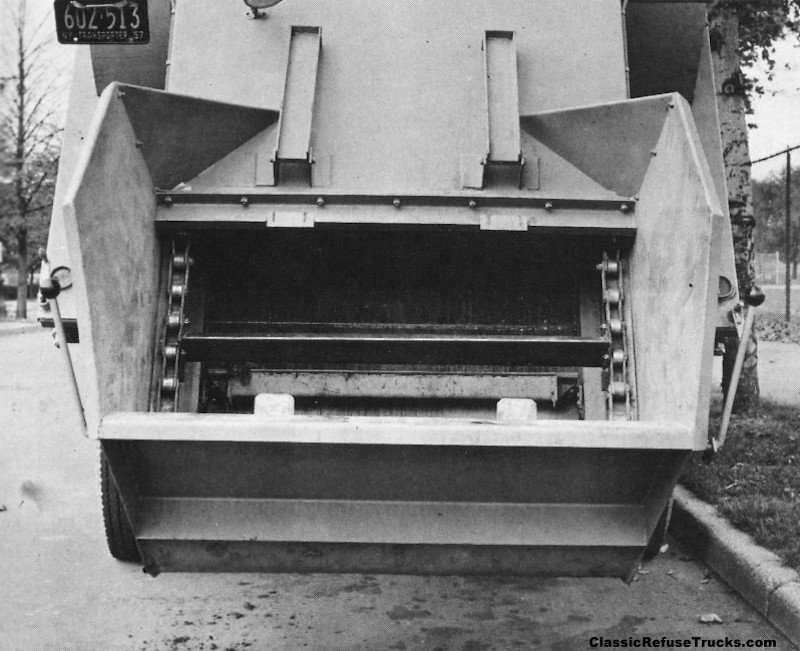

Close up of the new enlarged Roto-Pac hopper, showing the conveyor chains and flights. Levers at either side controlled start, stop and reverse functions. Accelerated engine speed of 750 RPM was recommended to maintain 35-40 flights per minute, with an increase to 1,000 RPM to maintain good compaction once the body became approximately two thirds filled. Folding 'barrel stays' mounted above the opening prevented trash barrels from contacting moving conveyor flights.

|

REVISED:

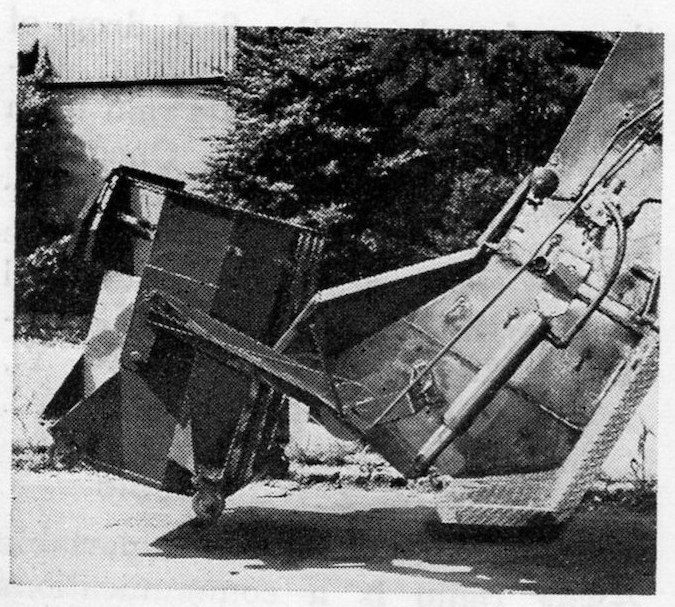

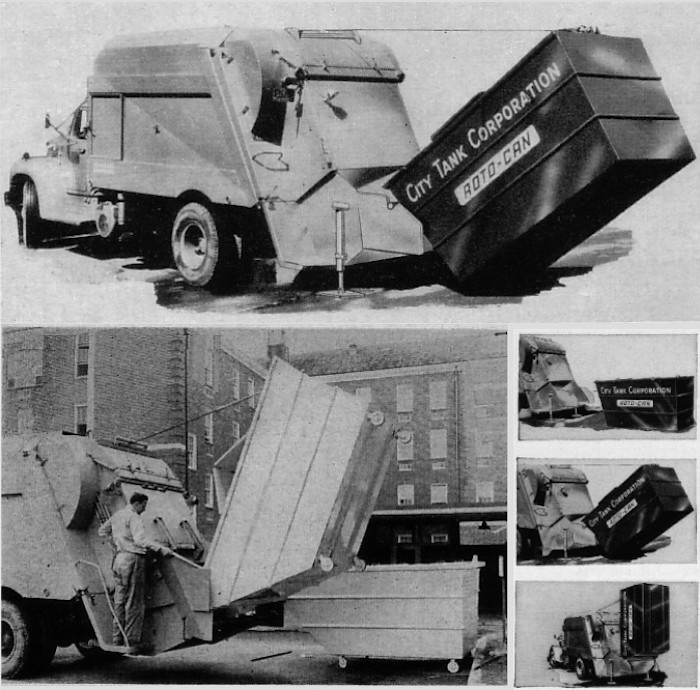

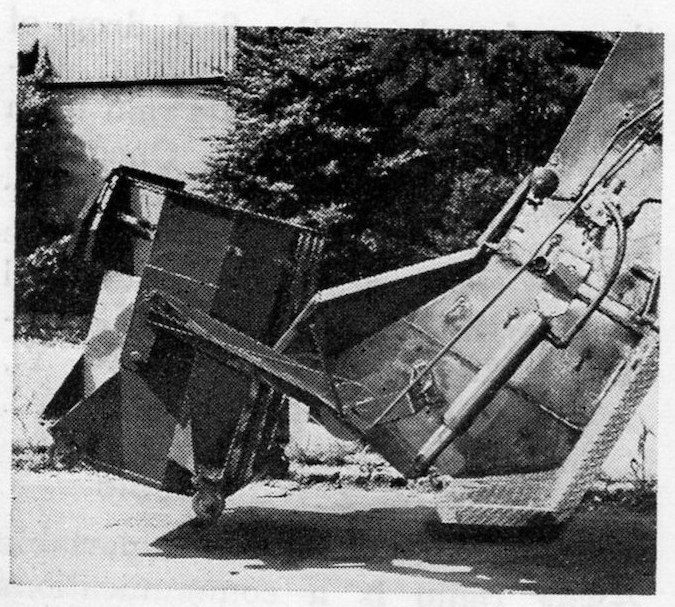

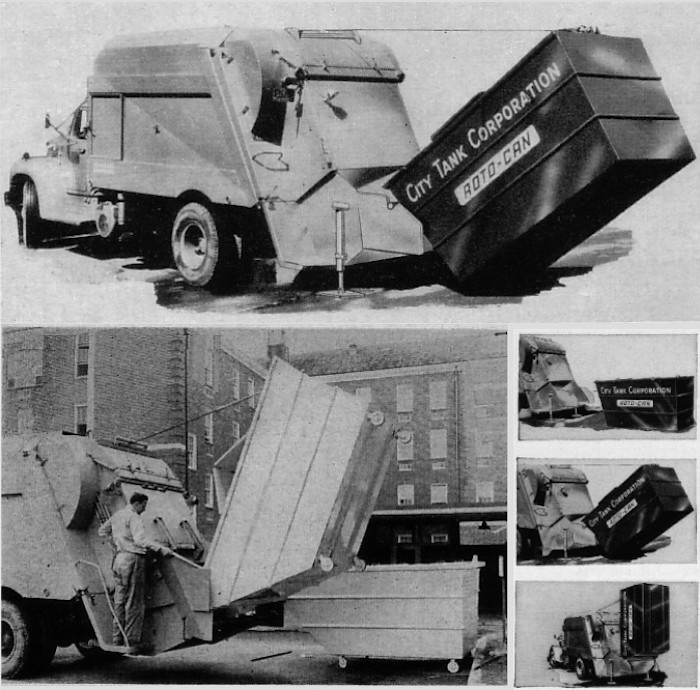

Another reason for the wider hopper opening was the introduction of the Roto-Can detachable container system. Announced in August of 1957, the new system utilized small cans of one cubic yard capacity. A pair of lift arms, mounted low on the hopper sidewalls and each fitted with a small hydraulic ram, served to hoist and empty the containers.

Above: early Roto-Can lift arm system

By 1958, the Roto-Can family expanded with a new range of 1-1/2 to six yard containers, now handled by a roof-mounted hydraulic reeving hoist and cable arrangement. Leach had pioneered the use of detachable containers on rear loaders with their 1955 Packmaster, and Gar Wood had followed suit in 1957. Both makes were limited in container lift capacity by the use of packer blade lifts and kick bars, respectively. By using the overhead hoist, Roto-Pac was (initially) the only rear loader that would handle the big cans. These container systems gave new versatility to the rear loader, which could now mix commercial container routes with the usual hand-loaded residential work. Contemporary advertising depicts outriggers attached to the Roto-Pac's hopper sidewalls, indicating that the relatively light body had some stability problems when lifting heavy containers. The use of outriggers was probably dependent on the combination of particular body sizes and truck chassis configurations.

Above: later Roto-Can lift with overhead hydraulic hoist

|

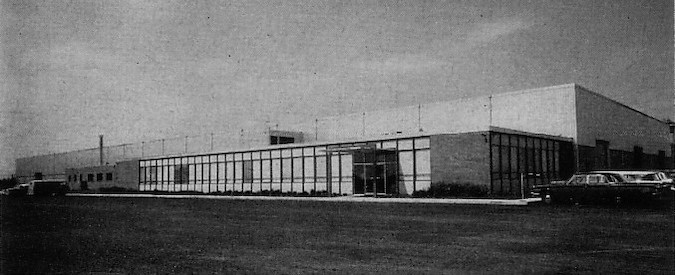

In early 1961, City Tank Corporation moved from their longtime home in Corona, Queens, to the rural hamlet of Culpeper, Virginia. The new home of the Roto-Pac was now a modern 100,000 square foot facility, seventy miles south of Washington, D.C. It was the largest factory in the refuse body industry at that time. The new shop would soon be very busy, filling a 1962 order for 250 Roto-Pac units for New York, the largest municipal contract for refuse trucks in history. The DSNY was now adding 20 cubic yard bodies to their fleet, as well as the traditional 16-yard Roto-Pac. Another order for 212 units was filled in 1964, making the DSNY collection fleet the world's largest, and ninety percent Roto-Pac. Chicago also placed a Roto-Pac order that year, for 75 twenty yard bodies and five 84" Alley Cats of ten yard capacity.

City Tank Corporation's new factory at Culpeper, Virginia

1958 Roto-Pac advertising illustration

Twenty cubic yard Roto-Pac delivered to a Chicago refuse contractor

Culpeper-built Roto-Pac from 1961

BrockwaY Roto-Pac for Rochester, New York (Waste Pro Museum)

BrockwaY with 20-yard Roto-Pac owned by a New York area hauler (Waste Pro Museum)

Demand for the continuous-loading escalator-compactor eventually began to wane. By the late 1960s, the conveyor-type loader, a design dating to the 1920s, had run its course. In what was probably the final blow to Roto-Pac, the DSNY ordered 800 batch-type rear loaders in 1968. Fortunately, half of that order was for Load-Masters, a new all-hydraulic model developed by City Tank in the early sixties. Even if Roto-Pac demand had remained steady, it is doubtful it would have ever been able to comply with ANSI safety standards. Roto-Pac was last known to have been advertised in 1972, and was presumably dropped from production the following year. City Tank began ramping up production of the Load-Master line, which included an 84" LM-200 'Alley Cat', the successor to the type pioneered by Roto-Pac and the City of Philadelphia in the early 1950s.

City Tank had survived the debacle of the early Roto-Pac in 1948, and quickly rebounded with a revised model, which carried the company for more than a decade. When demand for conveyor-loaders dried up in the 1960s, they were well positioned with the Load-Master, a modern and highly efficient hydraulic packer that would keep them competitive for the next quarter century.

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3027028 |

Disposal Mechanism and Canister Construction Therefor |

Robert A. Brown |

City Tank Corp |

April 19, 1957 |

7/4/10

© 2010

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|