Classic Refuse Trucks SHELVOKE & DREWRY

Classic Refuse Trucks SHELVOKE & DREWRY

Advances in the Design of Refuse Collection Vehicles

An Assessment of the Contribution made by Shelvoke & Drewry Ltd (1922-1991)

By Brian Carpenter

and Eric Voytko

INTRODUCTION: THE SHELVOKE & DREWRY FREIGHTER

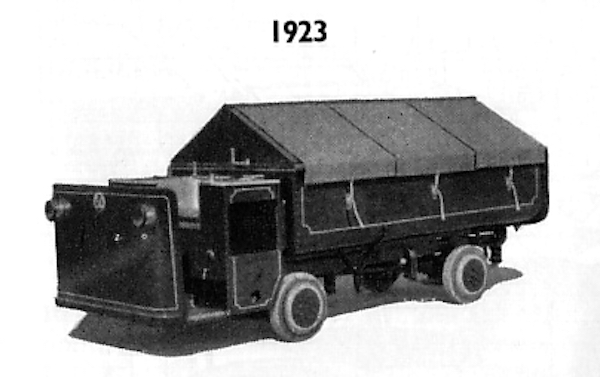

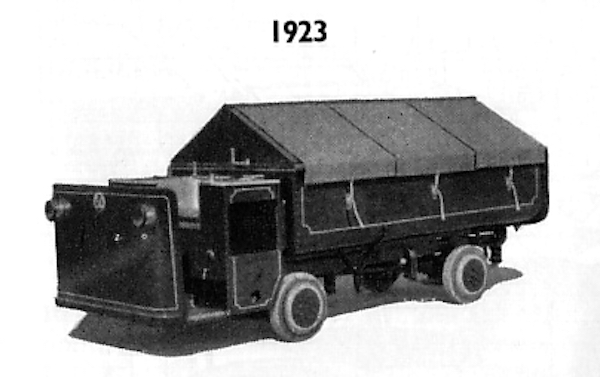

When Harry Shelvoke and James Drewry set up S&D to manufacture their unique design of small lorry, they thought of it as a general purpose vehicle. But very soon it gained popularity with municipal authorities for refuse collection, and this became the major use for the company's vehicles. Unlike many of their competitors, S&D manufactured both the chassis and the body. In many cases the Freighter of 1922, which is often referred to as "The Tiller", replaced horse-drawn wagons for refuse collection.

Its advantages were:

1. Its simplicity of control. Two levers, or tillers, controlled the vehicle situated to the right and left of the driver. One controlled the steering, the other the epicyclic gear box, which eliminated the need of a clutch pedal. The driver also had an accelerator and a brake pedal.

2. The diminutive 20-inch diameter solid rubber-tyred wheels permitted a low loading height, and eliminated punctures from landfill sites.

3. Hydraulic tipping was provided, where most competitors relied on manual means of tipping the body.

4. Automatic lubrication was provided to all moving parts, eliminating the need for regular greasing.

5. Canvas or steel shutters were fitted, to lessen the amount of dust discharged into the atmosphere from the previous open lorries.

In practice the vehicles were found to be more economical than the use of horse-drawn vehicles.

LATER DEVELOPMENTS: Mk II FREIGHTER

From 1931 pneumatic tyres became standard, as by now improvements in technology made these more robust. Treadle operated "dustless shutters" were offered from 1927, hydraulic operation of the shutters was introduced in 1929.

In the same year a fully enclosed cab with a compartment for loaders appeared.

In 1949 S&D fitted a Fore & Aft tipper body to the Freighter. Based on the German Faun design the body could be regularly tipped forwards to compact the refuse. This basic design was to become a popular specification for SD vehicles for over a decade.

|

THE SHELVOKE & DREWRY REYLOADER

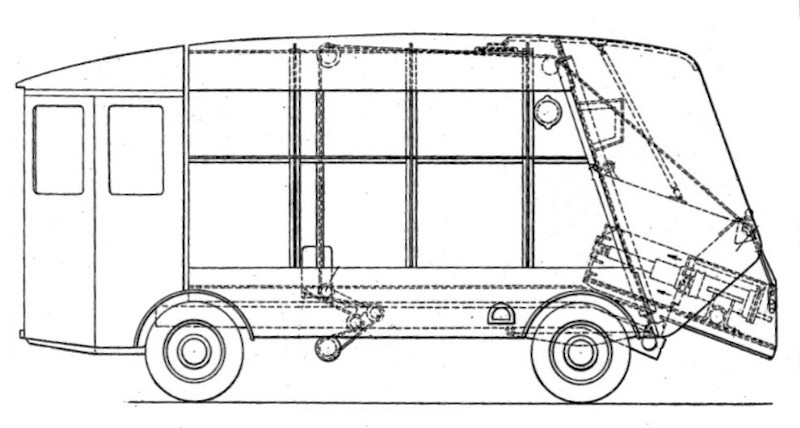

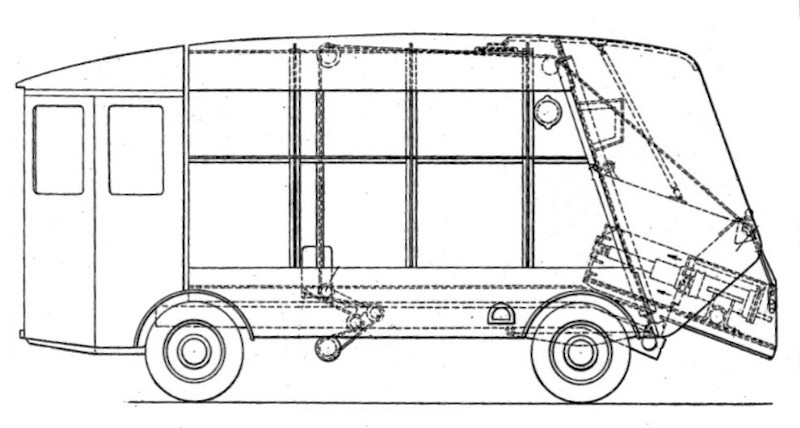

In 1936, Charles Kearns Edwards of London designed an improved version of the Reyloader, assigning patent rights to Fernand Rey. Shelvoke & Drewry obtained the rights to build this British Reyloader, and constructed a prototype which was tested by the County Borough of Walsall in early 1937.

To conform to British transport regulations, the SD version differed radically from the Reyloaders in use by SITA in Paris. The nine cubic yard body was less than half the capacity of the SITA trucks, with lighter bracing on the body sides. The tailgate and loading hopper appear to have been a great improvement over the French versions, being compact with less overhang, spanning the full width of the body. Indeed, the tailgate foreshadowed the SD Pakamatic body of the future. It was attractively styled, with the cables and pulleys for the tailgate lift concealed behind panels, and a small compartment to carry crewmen was integrated into the front portion. The body assembly was mounted on the SD Freighter chassis.

By contemporary accounts, the trial was an unqualified success. Borough authorities were particularly impressed with the ability of the packer to reduce bulky shop waste to a fraction of its original density. As a result, at least one completed vehicle was ordered by Walsall and placed in service. The Walsall trials further piqued curiosity in England regarding Rey's groundbreaking concept, and its adaptability to the British market.

In fact, a small war of words erupted in the publication Commercial Motor between C. N. Graddon, Walsall's Cleansing Superintendent, and Tom Tillson, who was then employed in the engineering department of SD's rival, Dennis Brothers of Guildford. At the time, Tillson was opposed to the concept of compaction bodies, and believed theses vehicles to be too heavy and complex for the British market, as well as overly expensive to operate. These facts were as vigorously contested by Mr. Graddon, in a good natured exchange published during early 1937. Graddon maintained that the efficiency of the packer mechanism more than made up for any loss in economy, alleged or real.

Tillson's school of thought won the day, at least temporarily, as the SD Reyloader was ultimately a commercial failure. However, Tillson would go on to brilliant career at Dennis, who marketed the successful Paxit compression refuse bodies after the war. His 47-years in the industry culminated with twenty spent at Shelvoke & Drewry. In a somewhat ironic twist, his later years at SD found him involved with development of the Pakamatic and Revopak series, both of which were Fernand Rey designs adapted for the British market!

|

REFERENCES

The Commercial Motor: March 19, 1937 (page 93)

Walsall's New Way with Waste by C.N. Graddon

The Commercial Motor: April 9, 1937 (page 39)

OPINIONS: Is The Compression of Refuse Worth Wile? by T.W. Tillson

The Commercial Motor: May 14, 1937 (page 45)

REPLY: Experiences with the S.D. Freighter Self-Loader Refuse Collector by C.N. Graddon

|

10/1/04 (Revised 1/17/10)

© 2004, 2010

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|