In The Beginning: Fernand Rey and the "Rey Loader"

By Eric Voytko

With motor trucks gaining in popularity as municipal refuse collectors, the 1920s saw the beginnings of what would become an entirely new industry: the specialized refuse collection body. At first, developments were mostly confined to sealing hand-loaded collection bodies to prevent dust, liquids and odors from escaping. In some cases, efforts were made to lower overall loading height to ease the strain on the men tasked with loading the trucks.

The oil-hydraulic hoist was already being adapted to tip all manner of truck bodies, replacing earlier hand-cranks or manual unloading. German manufacturers Krupp and KUKA soon began producing self-loading bodies specifically designed for refuse collection, using mechanical power from the vehicle engine. They were the first designs that actually relieved the the burden of loading the truck, and delivered a beneficial side effect; load compaction, which increased the capacity of enclosed bodies significantly.

In the 1920s, Paris, France was home to one of the largest fleets of motor refuse trucks in the world, operated by a contract collector known as SITA, which is an acronym for Société Industrielle de Transports Automobiles. One of four companies serving the city, SITA operated a fleet of of several hundred Schneider 7-ton cab-over-engine trucks with hydraulic-dumped enclosed steel bodies. Many had been in use since 1922, and had proven satisfactory in their duties and were in top condition, thanks to a rigorous maintenance program.

Under pressure from the Paris city government to modernize collection methods, SITA was faced with the dilemma of replacing their perfectly serviceable fleet of vehicles at great expense, while meeting their contract obligations. Fortunately, their Chief Engineer, Monsieur Fernand Rey arrived at a solution to the problem, which was to "re-power" a great many of the Schneider trucks with an enclosed steel body of his own design, which featured a novel, hydraulic-powered packer blade. Rey may not have realized it at the time, but he invented the modern refuse packer, and forever altered the course of refuse body design.

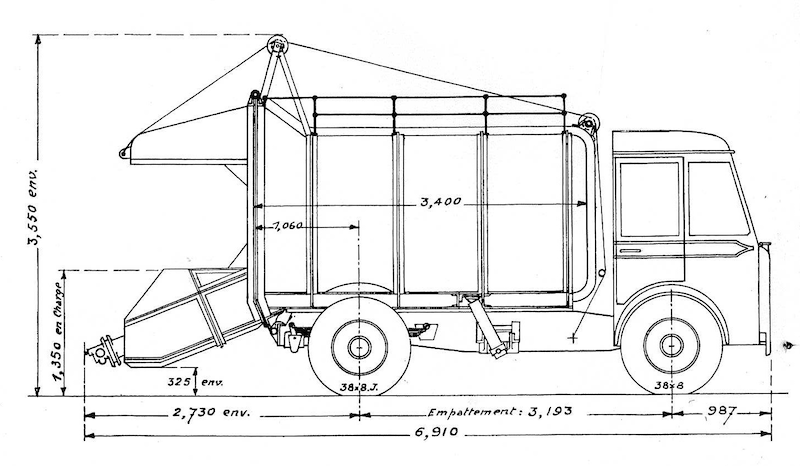

When exactly, the first models went in to service is unknown, but Rey had filed a patent application in Paris by June of 1933. The patent described the invention as a loading bucket attached to either the front, sides or rear of an enclosed truck body. As built, it was a rear loader, with a body constructed of reinforced steel and a capacity of 21 cubic yards. Two feet were removed from the Schneider truck chassis, as the new body was shorter and taller than the old dump beds. The body was hoisted hydraulically, with a set of cables which simultaneously raised a hinged tailgate section when dumping.

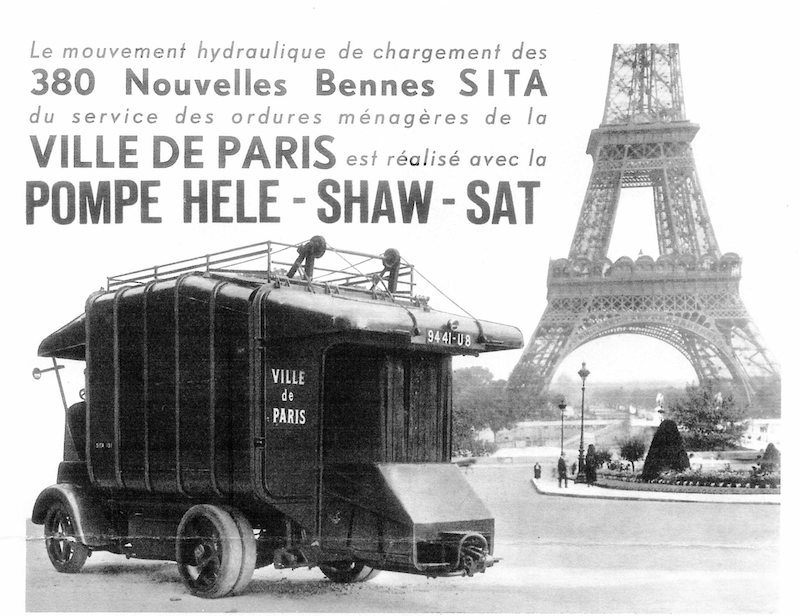

Schneider truck with Reyloader in front of the Eiffel Tower, from a 1934 advertisement for Hele-Shaw hydraulic pumps.

The ad mentions 380 new refuse trucks being equipped with their pumps by SITA for the City of Paris.

Fernand Rey not only invented the hydraulic rear loader, he also built the world first municipal fleet of them

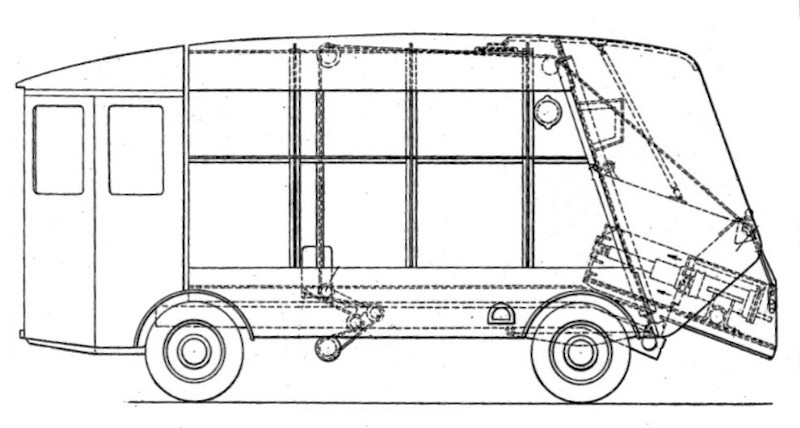

Attached to the back of the tailgate was a narrow loading bucket or hopper, which inclined gradually up to meet the body at floor level. The hopper was swept by a simple packer plate of what is now termed the "inverted drawer" type, which pushed the refuse up into the body and compressed it as the body became filled. A simple double-acting ram provided the power, pushing and pulling the blade alternately. As refuse was loaded, it fell either in front of the blade, or on top of the blade shield depending on the position of the ram. Refuse landing on top of the shield would fall down in front of the blade as the ram retracted. The first versions were fitted with electric powered Hele-Shaw type hydraulic pumps, current being supplied by an alternator. These were soon upgraded to a direct-drive pumps using a power take-off arrangement.

Between 1934 and 1936, there were 450 of the new bodies placed in service. Many early models were produced by the SITA shops, though it is possible and quite likely that local metal fabricators and body shops were eventually contracted to keep up with the demand. Though bearing no official brand name or model, they have come to be known as "Rey Loaders" or "Reyloaders". Contemporary accounts indicate that the new packer was an unqualified success. A single Reyloader performed the work of three of the older, hand-loaded trucks. In addition to the driver, only two loaders were needed, the fourth man being eliminated. There were actually very few moving parts used in the packer, all of which were easily accessible within the tailgate structure. Before long, the city and SITA were rewriting their contract agreement in light of this newfound efficiency.

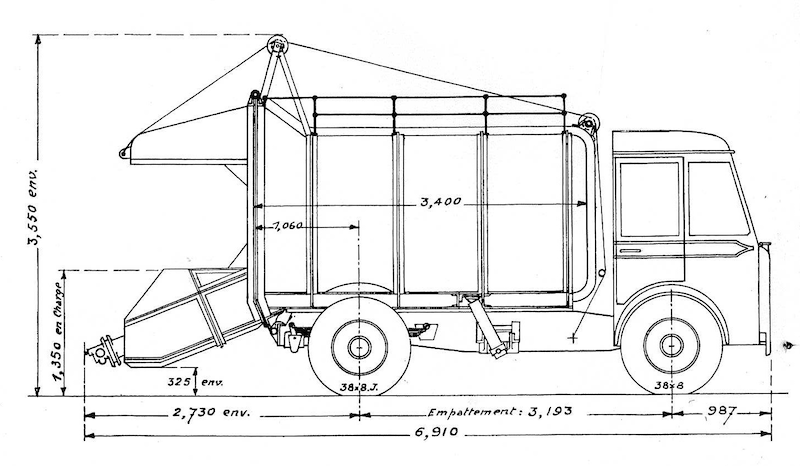

Typical Reyloader construction, with hydraulic packer/hopper affixed to tailgate, and canopy above. Body is emptied by underbody hydraulic hoist,

and tailgate is drawn open by roof-mounted cables, anchored at the chassis frame, as the body rises.

Left: Two workmen empty bins into the Reyloader bucket, which had easy access and low loading height.

Right: Strip curtains pulled back to show overflowing hopper, as continuous-cycling packer blade churns below.

During the 1930s, Rey licensed his design to manufacturers for sale throughout France and Europe. Bergomi of Italy is known to have built a Reyloader, and a British version was produced by Shelvoke & Drewry (SD) for the borough of Walsall. The SD version was vastly different in appearance from the trucks used in France, and only a handful were ever built. It did, however foreshadow a future relationship between Rey and SD, which would come to fruition in the 1960s.

In France, the Reyloader was eventually manufactured under license by an equipment and body manufacturer SCEMIA, which had a close association with Renault Motors. During the occupation of France by Nazi Germany during the 1940s, Renault factories were bombed by Allied Forces as the firm had supplied trucks to the German Wermacht. The occupation and bombing surely disrupted refuse truck production during this period, and although SCEMIA resumed operations after the war, it is not known if they resumed building Reyloaders. Post-war Reyloaders were known to have been sold commercially by Laffly, at least for a while. Most notable was the 1948 model, paired with a Vetra battery-electric truck, many of which were employed in the SITA fleet.

After licensing his designs for many years, Fernand Rey eventually founded Societe d'Equipements, Manutentions et Transports (SEMAT) in 1950 to capitalize on his patents. Modernized versions of the Reyloader were subsequently produced under the SEMAT marque, which would go on to become one the major manufacturers of refuse bodies in Europe.

The contributions of Fernand Rey to the worldwide development of the refuse packer cannot be overstated. The Reyloader was the world's first mass-produced hydraulic refuse packer. They were years ahead of their time in function and appearance, when the most common collection method was a hand-loaded dump truck. The "sliding drawer" packer blade method of the Reyloader remained poplar in Europe for many years, well into the 1960s, and has been widely copied. Furthermore, it has been improved and adapted to many different types of refuse trucks over the ensuing decades, right up to current times where it is the heart of many mechanical and automated side loaders.

THE SHELVOKE & DREWRY REYLOADER

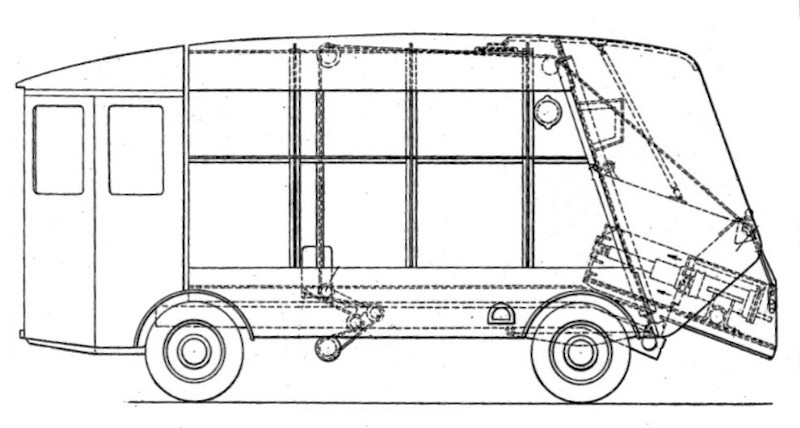

In 1936, Charles Kearns Edwards of London designed an improved version of the Reyloader, assigning patent rights to Fernand Rey. Shelvoke & Drewry obtained the rights to build this British Reyloader, and constructed a prototype which was tested by the County Borough of Walsall in early 1937.

To conform to British transport regulations, the SD version differed radically from the Reyloaders in use by SITA in Paris. The nine cubic yard body was less than half the capacity of the SITA trucks, with lighter bracing on the body sides. The tailgate and loading hopper appear to have been a great improvement over the French versions, being compact with less overhang, spanning the full width of the body. Indeed, the tailgate foreshadowed the SD Pakamatic body of the future. It was attractively styled, with the cables and pulleys for the tailgate lift concealed behind panels, and a small compartment to carry crewmen was integrated into the front portion. The body assembly was mounted on the SD Freighter chassis.

By contemporary accounts, the trial was an unqualified success. Borough authorities were particularly impressed with the ability of the packer to reduce bulky shop waste to a fraction of its original density. As a result, at least one completed vehicle was ordered by Walsall and placed in service. The Walsall trials further piqued curiosity in England regarding Rey's groundbreaking concept, and its adaptability to the British market.

In fact, a small war of words erupted in the publication Commercial Motor between C. N. Graddon, Walsall's Cleansing Superintendent, and Tom Tillson, who was then employed in the engineering department of SD's rival, Dennis Brothers of Guildford. At the time, Tillson was opposed to the concept of compaction bodies, and believed theses vehicles to be too heavy and complex for the British market, as well as overly expensive to operate. These facts were as vigorously contested by Mr. Graddon, in a good natured exchange published during early 1937. Graddon maintained that the efficiency of the packer mechanism more than made up for any loss in economy, alleged or real.

Tillson's school of thought won the day, at least temporarily, as the SD Reyloader was ultimately a commercial failure. However, Tillson would go on to brilliant career at Dennis, who marketed the successful Paxit compression refuse bodies after the war. His 47-years in the industry culminated with twenty spent at Shelvoke & Drewry. In a somewhat ironic twist, his later years at SD found him involved with development of the Pakamatic and Revopak series, both of which were Fernand Rey designs adapted for the British market!

|

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2050806 |

Loader for refuse vehicles |

Rey |

|

June 27, 1933 |

|

US2130951 |

Loading apparatus for vehicles (SD 'Walsall' loader) |

Edwards |

Rey |

May 2, 1936 |

1/6/13

© 2013

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

|