SEMAT

Societe d'Equipements, Manutentions et Transports

(Transport and Handling Machinery Company)

By Eric Voytko

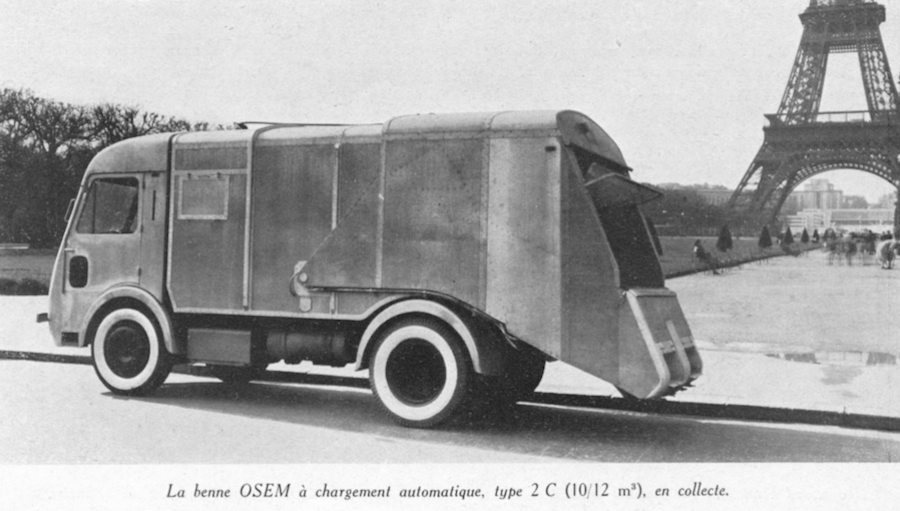

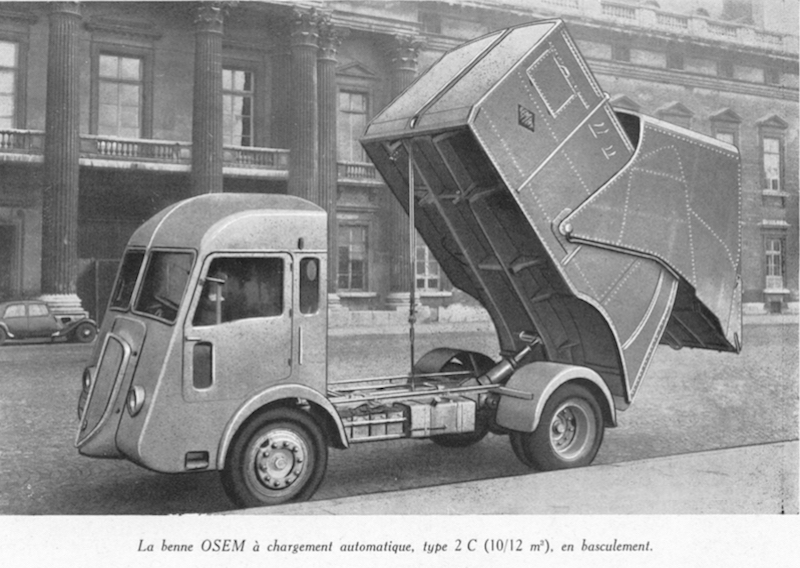

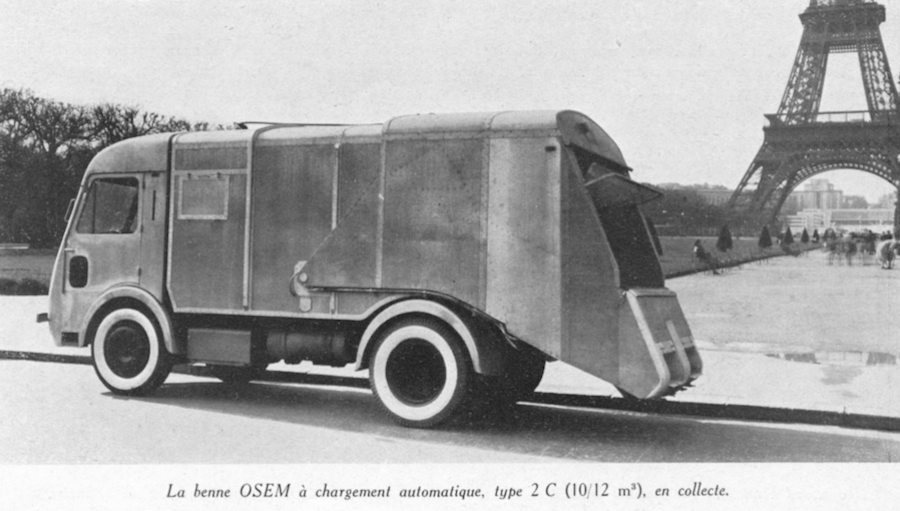

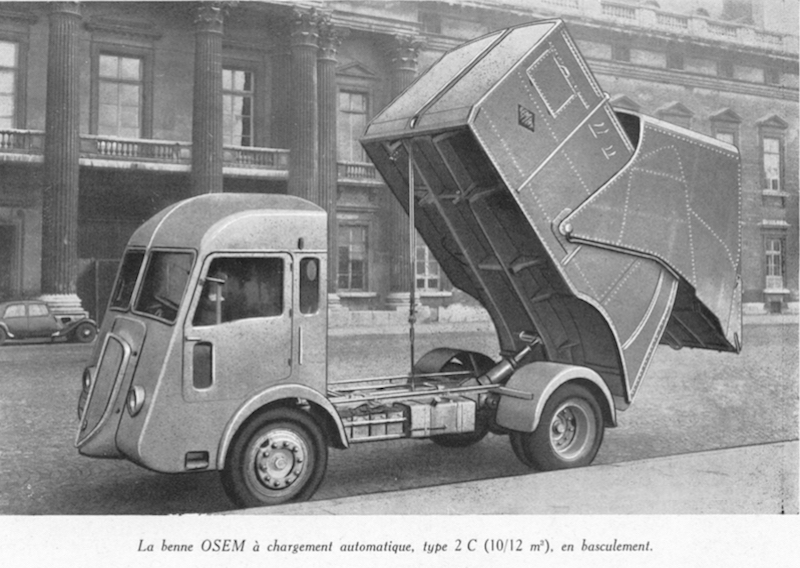

Early SEMAT, Benne OSEM

Early 1950s SEMAT model OSEM with Ochsner-style cable-operated tailgate lift

With a staff of three people, SEMAT was founded in France in May of 1945 by Fernand Rey, who had developed the worlds first hydraulic rear loader for SITA during the 1930s. Rey founded the company to take advantage of his patents, and initially contracted work to established builders such as Laffly.

In 1950, Rey took over Constructions Industrielles de Versailles (CIV), a company with ample facilities to manufacture his refuse bodies. For the next twenty years, all refuse equipment would be produced through SEMAT-CIV. In addition to the Reyloaders that had become the main body for SITA, a new model was introduced which used the same basic packer concept as the 1930s Reyloader, but sported lighter bodies and a full-width loading hopper, and sold as Benne OSEM. These are believed to be licensed versions of the Ochsner System packer which had been popular in France and other European countries before the war (Ochsner SystEM). Though derived from the original Rey concept, this body had significant differences, such as alloy panels and a unique tailgate/canopy that was raised by a single cable as the body raised. The packer panel was a direct thrust type which normally rested against the rear of the hopper, with a protruding ram housing which extended into the loading hopper itself. Since it lacked a follower plate, it was not a continuous loader; re-loading could commence only when the cycle had completed.

The Benne OSEM bodies are outwardly indistinguishable from those made by Ochsner, except for the diamond-shaped logo affixed to the side of the body on most SEMAT models. It was adaptable to dustless bin systems made by Ochsner and others, and joined the fleets of SITA and CGEA in Paris, where they worked alongside Reyloaders and Salubras during the 1940s and 1950s. The OSEM was phased out as more modern versions were introduced by the 1960s.

Benne OSEM (Ochsner System) Packing Cycle

Refuse is loaded into hopper, in front of packer blade which rests in its 'home' position at the extreme rear of the tailgate. Withe the blade in this position, note how the hydraulic cylinder housing projects into the hopper area.

|

Operator commences cycle, and packer blade moves forward, pushing refuse forward and upward through a passage leading to the body. If equipped, shutters over the hopper may be closed to prevent refuse from falling back behind the advancing blade.

|

Successive cycles push more refuse over the pile and into the front of the body. Once the body is full, the packer compresses the load.

|

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US2062924 |

Vehicle for collecting and transporting refuse |

Ochsner |

|

March 11, 1935 |

7/4/11 (revised 3/24/20)

© 2011, 2020

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|

|