Superpac II and Superpac Gallery

SUPERPAC II

In 1977, SEMAT was acquired by Compagnie Générale des Eaux (CGE), a conglomerate that was at that time branching out into the solid waste management field. CGE subsequently bought out Compagnie Générale d'Entreprises Automobiles (CGEA), a large private waste contractor in 1981.

The last generation Superpac II arrived around 1987, and featured a revised steel body and streamlined tailgate structure, with two smaller access covers for the hydraulic rams. The rake teeth were changed again, deleting the flat "blade" faces and reverting to a very narrow width. The profile was enlarged, with a c-shaped cut-out which formed a type of claw. This was likely due to the changing composition of the refuse stream, which consisted primarily of plastic sacks. The new tine shape appears to be ideally suited to dragging and breaking sacked refuse. The ejector panel was revised for the Superpac II, changing from horizontal to an angle-mounted ram.

By the 1990s, the days of continuous-loading packers were numbered, and the Superpac II was replaced with a modern intermittent loader. High fuel consumption, wear and noise contributed to the demise of these machines, and the inherent safety hazard of a revolving rake was no longer acceptable. The cancellation of the Superpac II marked a historic milestone, ending more than 60 years of Fernand Rey-designed refuse packers being produced in France, mostly by SEMAT. However, every modern side and front loader with an inverted-drawer packer carries on his legacy to this day.

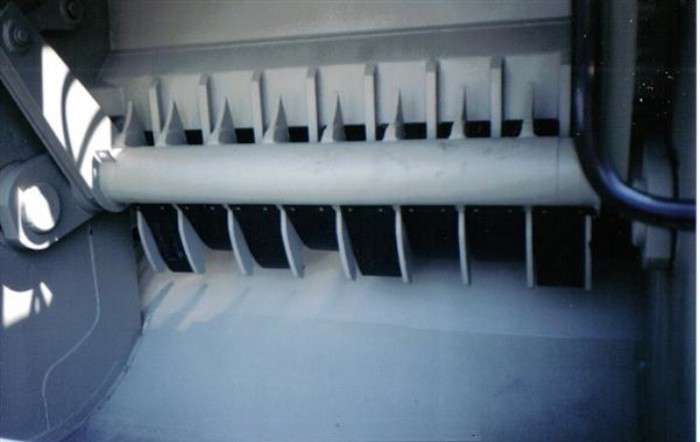

The rugged packer of the Superpac II, taken at a 1994 equipment exposition

Inside view of packer: (Left) revolving rake approaches end of orbit, forcing refuse through opening and fixed tines and into body (Right) at end of orbit, rake passes through fixed tines, and as next orbit begins, rake is pulled upward. Some refuse is caught and shredded by the fixed row, which also keep rake from clogging. Note the "claw" shape of the tine when viewed from the side.

View of LH pack cylinder, with access panel removed. Reciprocating action of ram is converted to rotary motion by means of a crank arm and an automatic reverse valve operated by the integrated cam.

The angle-mounted ejector used on the Superpac II

SUPERPAC GALLERY: MISCELLANEOUS IMAGES

Superpac BR with dual binlift for plastic bins

Rare Superpac BR on tandem chassis with special lift for handling skips

Superpac semi-trailer retained the original-style tailgate for a few years after the BR was introduced

Later model semi-trailer with the Superpac BR tailgate

Superpac stationary unit; notice the sharp angles on the fixed row tines!

The Mini-Benne was a satellite vehicle designed to dump into the hopper of a Superpac

Mini-Benne on Honda chassis emptying its load into a Superpac BB rear loader

Lightweight Mini-Benne on 3-wheeled chassis

Lightweight Mini-Benne on automobile-type chassis

The rare Robopac ASL, with a variety of residential bins

Robopac's Palfinger lift arm with clamshell type street container

7/4/11 (revised 5/16/21)

© 2011, 2020, 2021

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|