Wayne Gruncher

(A.K.A. Imperial GT, Wayne Turbo)

1976 Wayne Imperial GT; later renamed The Gruncher

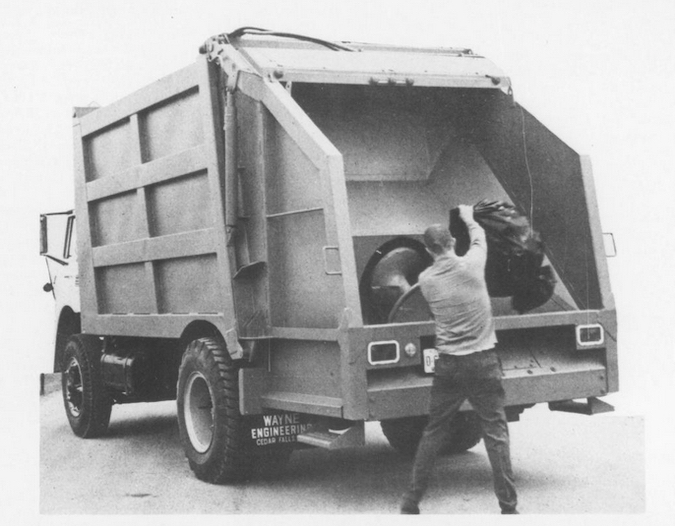

Not content with merely being a "small body" manufacturer, Wayne released their first full-size rear loader in 1976. Rather than upsizing the Royal GT rear loader, Wayne shocked the industry with the Gruncher, America's first mass-produced auger-type rear loader. It was basically the Swedish Norba design, mated to a Wayne-style rear loader body, and ranging in sizes from 16 to 25-cubic yards. This was a bold move, but the Norba design had already proven itself, with over 40 years of reliable service under its belt across Europe and the UK. The constantly rotating auger ripped and shredded virtually any type of refuse, leaving only small shards to compact in the body. Thus, very high payload density could be achieved with relatively simple and light weight packer. Wayne advertised compaction density at 800 to 1,000 pounds per cubic yard.

The new packer made its debut in June at the NSWMA convention in Chicago, as the 20-yard Imperial GT. It was advertised for sale the following month, but the name had been changed to Gruncher, a more descriptive moniker for the auger-compactor. The first unit was ordered by Keith Sanitation Service of Clear Lake, Iowa. Selling American refuse contractors on the design would not be easy, since the slide-sweep rear loader had become so ingrained in the industry. To the uninitiated, an auger screw compactor may seem incapable of handling bulk refuse, but a demonstration would quickly allay any such fears. Properly constructed, the the high-torque screw rips through any type of refuse, reducing furniture to splinters and cloth! Ultimately, the Gruncher was probably introduced too late. A renewed emphasis on safety and economy in the 1970s made continuous-type loaders fall from favor, even in their own European strongholds. It was in fact the American slide-sweep design that was replacing such icons as the Norba, SD Revopak, Dennis Paxit and SEMAT Superpac.

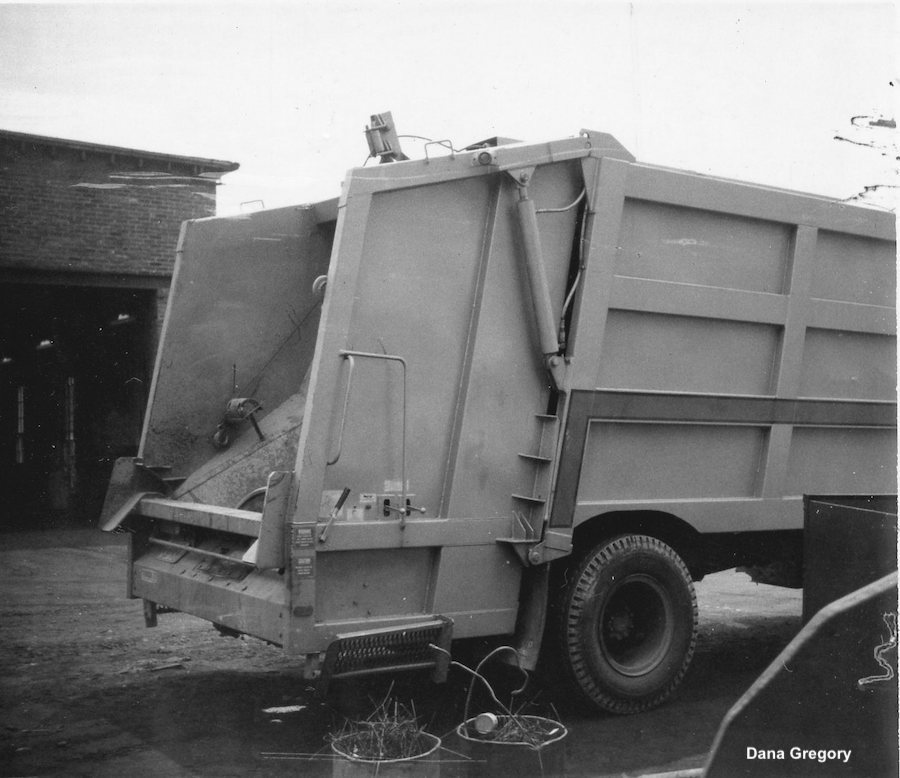

Wayne did an admirable job selling the Gruncher, with clever national advertising campaigns. For 1980, the auger gearbox was replaced with direct hydraulic drive, and a reduced-weight, semi-curved body shell was introduced, similar to the discontinued 1977 Gar Wood LP-10 00. The new body shell was way ahead of a trend which would sweep the rest of the industry in the coming years. The model stayed around until the end of the decade, being renamed The Wayne Turbo, probably in attempt to capitalize on the current automobile marketing trend. After the demise of Gruncher, Wayne would once gain try and break into the large-size rear loader market with yet another Norba design, albeit a far more conventional packer with greater potential appeal to American users.

1977 Wayne Gruncher

1977 Wayne Gruncher demonstrator unit on Ford L-Series truck chassis

Gruncher tailgate was designed by Norba of Sweden, featuring auto-locking tailgate

The ejector blade looks more like that of the Gar Wood LP-900

The awesome Gruncher screw, driven by a hydraulic motor through a reduction gearbox

Auger screw tapers as it enters the choke plate leading into the body

View of the choke opening from inside the tailgate

View of the hydro motor and gearbox, from underneath tailgate; the assembly weighed 835 pounds

Fleet of very rare 25-yard Grunchers and their crewmen

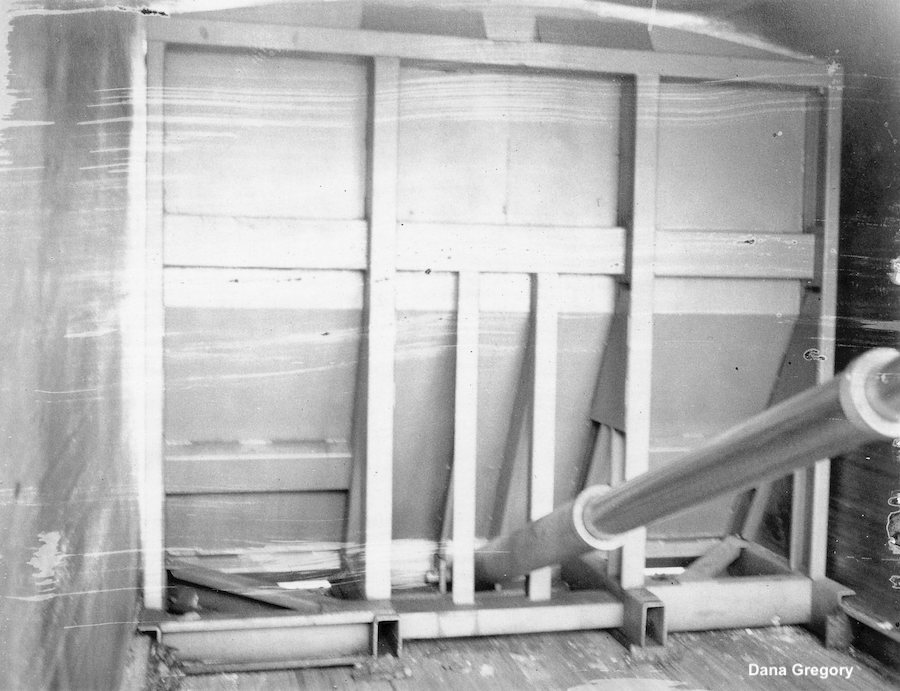

STILLBORN: THE WAYNE REVOPAK

In deciding to build a continuous-loading packer, Wayne Engineering had considered more than just the Swedish Norba design. Also in the running was the famous SD Revopak, a model beloved by many classic refuse truck enthusiasts. This was relayed by longtime CRT contributor Dana Gregory. In deciding to build a continuous-loading packer, Wayne Engineering had considered more than just the Swedish Norba design. Also in the running was the famous SD Revopak, a model beloved by many classic refuse truck enthusiasts. This was relayed by longtime CRT contributor Dana Gregory.

Gregory received a set of photographs from Wayne General Manager Stan Worthington depicting a special version Revopak with a slightly lower rave rail (hopper sill) that was reportedly designed to interest American manufacturers:

" I met him personally a couple of times, and he was a gentleman. He explained why Wayne chose the Norba auger screw design over the Revopak. It was a matter of production cost and the high maintenance of the Revopak design."

|

View of the auger with direct hydraulic drive, introduced in 1980

Gruncher also got a new semi-curved shell body in 1980

This advanced body was years ahead of its time

REFERENCES

Solid Wastes Management/Refuse Removal Journal, May 1976, page 138

1976 NSWMA Show Highlights

Solid Wastes Management/Refuse Removal Journal, November 1977, page 19

The Best Packer Body I Ever Bought (advertisement)

Solid Wastes Management/Refuse Removal Journal, August 1980, page 111

New Products: Screw Compactor

|

7/4/2020 (revised 3/7/21)

© 2020

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|