|

Wayne Curbtender

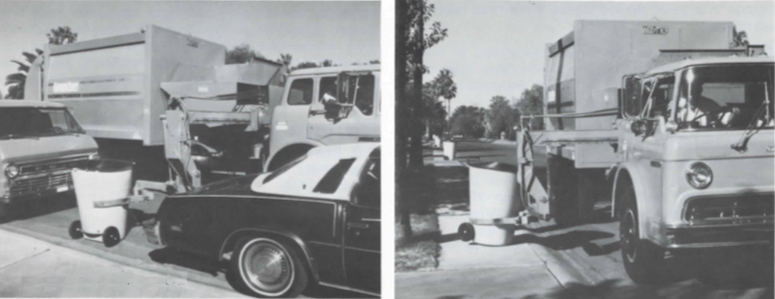

The 1978 Rapid Rail Mark VI Gruncher ASL, designed by Stanley Worthington, was the predecessor of the Wayne Curbtender It was a bold move for 1978, but Wayne was perfectly situated to enter this growing market. Being a small-volume manufacturer, they could profitably build for the small initial demand, and hone their skills as the market grew. This gave a Wayne a head start over the big three refuse body builders (Gar Wood, Heil and Leach), which didn't even have an ASL on the horizon in the late 1970s. Worthington originally partnered with Rapid Rail to market his ASL as the Gruncher Mark VI. Wayne was a company that used partnerships to great advantage. Marc Stragier's newly-formed company Government Innovators was the organization behind Rapid Rail, a chain-drive lift arm he developed for use on a standard side loader. Stragier is often called the "Father of Automation" for his groundbreaking work for the City of Scottsdale, Arizona experimental ASL program. Rapid Rail would soon become the brand name for Stragier's own ASL design, the Swinger. The Mark VI Gruncher was derived from the Wayne auger-type rear loader body developed a year earlier, and based on the Swedish Norba design. It was reconfigured for front-end intake and tilt-to-dump, and the auger fed the body from a side-loaded trough. The constantly churning screw devoured the refuse as it was fed by the loader arm with a clamshell gripper. A unique twin-boom lift carriage had c-shaped arms, much like a front loader, allowing the rearmost arm to clear the intake passage from hopper to body. FIRST GENERATION CURBTENDER

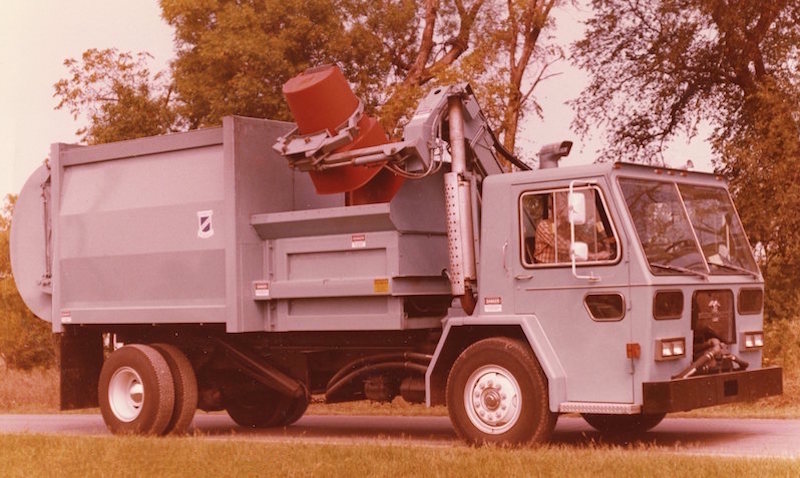

The advanced Wayne Curbtender Gruncher featured a new lift arm with 66-inch reach The beautiful semi-curved body was dropped in the mid-1980s, possibly due to its expense, and the fact that such durable construction wasn't needed in this type of packer. A lighter, 25-yard vertical-rib steel body replaced it, as arm reach extended to 78 inches for a 90-gallon cart. The Curbtender could service 600-1000 stops per day, and helped to "mainstream" automated collection in communities across America.

Greenville Mississippi bought one of the first Wayne Curbtender Grunchers, shown here on residential carts

Curbtender Gruncher shown with 300 and 90-gallon polyethylene containers

Reaching out with its 66-inch boom for 90-gallon wheeled carts

The Curbtender Puncher replaced the auger screw with a push-type packer blade

A simpler vertical rib body arrived for the Puncher around 1985

Eventually the body was simply known as the Curbtender SECOND GENERATION CURBTENDER

The next generation Curbtender arrived in the 1990s, and to most people is probably the most familiar of all the versions. The body was completely radiused, with no ribs, in 16-31 yard capacities. The traditional tilt-to-dump versions featured an integrated hopper, and used one single-stage 6.5" cylinder for packing. The big news was an all-new full-eject model, with a rail-guided blade, riding atop an I-beam at the center of the body floor. A single telescopic cylinder, horizontally mounted and projecting through, powered the tall packer panel through the length of the body to eject the load in stages. For packing, the blade could reach deep into the body to reduce fallback. AR400 steel was used in the sidewalls and guide bar. A train of follower plates were connected to the panel to allow continuous loading no matter where the packer was positioned in the body. The roller-guided plates stacked up at the front of the body when the blade was in the "home" position. The new full-eject Curbtender not only eliminated tilting to dump, it also solved the problem of hopper congestion typical of short-stroke, shallow-blade ASLs. An optional arm extender was available on these models, now reaching out up to 10-feet. With the trend towards automation now coming to full fruition, Wayne was ready with a modern and proven design, and experience working with cities to build new systems. In 1995, Wayne once again partnered with another manufacturer, this time the Leach Company of Oshkosh, Wisconsin. Leach would distribute and service the Curbtender, adding it to their line of popular rear and front loaders. These were identical to the Wayne product, and called Curbtender, except with Leach badging.

The full-eject Curbtender had a segmented follower and deep body penetration while packing

Bodies as small as 16-cubic yards could be specified. This is a 20-yarder with arm by Rand Automated Systems.

View of follower plate segment stowed in the body header as the blade was retracted

Packer blade shown partially extended into hopper

Full-eject packer blade, as viewed from inside the body

With an optional extender, the full-eject Curbtender had a 10-foot reach

27-yard tilt-to-dump Curbtender

Grabbing and dumping a 90-gallon cart

Eye-catching paint job for Phoenix, Arizona recycling

In partnership with Wayne, Leach Company began distributing the Curbtender in the 1990s

27-yard Leach Curbtender tilt-to-dump model

20-yard Leach Curbtender full-eject model

SELECTED PATENTS

|