Hot on the heels of unitized Gar Wood TX-30 unitized refuse truck, which was unveiled in late 1964 at the APWA Equipment show, Western Body & Hoist announced an all-new refuse truck of their own; the Wesco Jet front loader. This was a joint project with Reo Motors of Lansing, Michigan, which did the development and engineering on a short-wheelbase truck chassis, with an almost perfect weight distribution. Designated as the Reo AF-475, The cab and engine were mounted fully forward of the front axle, so that the truck body would rest directly on both axles. With a wheelbase of 140-inches, the Jet was also highly maneuverable for a vehicle of this size. Mated to the Jet chassis was an all-new front loader designed by George W. Morrison, engineer and co-founder of Western Body & Hoist. It was based on the Full-Pak front loader, with a 35-cubic yard capacity and a unique sloped rear floor section to ensure complete ejection. Where the Jet completely departed from the Full-Pak was in its lift arm design, consisting of narrowly-spaced arms operating between the frame rails, instead of the more traditional outboard mounting arrangement. This was a significant advance in safety, while avoiding infringement on Dempster's patent for curved "over-the-cab" arms. To make room for the centrally-mounted arms, the cab was essentially split in two, leaving a pair of small "telephone booth" cabs for driver and helpers. A single booth could also be specified. There were two distinct types of lift arms used on the Jet. Both versions rode on a torque tube mounted behind the cab and above the frame rails, operated by vertically stacked cylinders. Early model arms (1965 to about 1968) were hinged about halfway along their length, with a set of tilt cylinders used to flip the container over the body opening. These were similar in concept to the very first Bowles arms dating to 1952. Later versions (about 1968 and up) were built with more conventional rigid arms, the fork pivot points having moved to the ends where the fork carriage mounted.

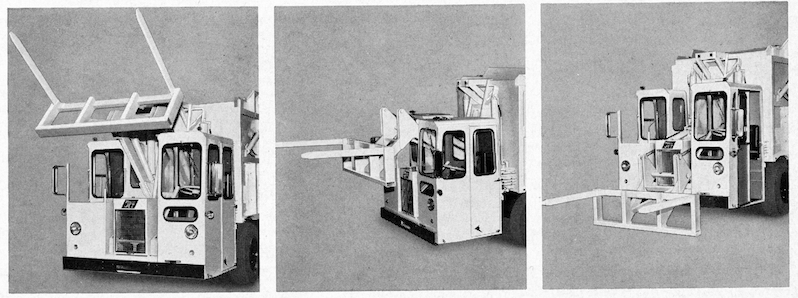

Early model Jet with split-type lift arms and bottom-type forks

Operation of the split-type lift arms with optional side forks.

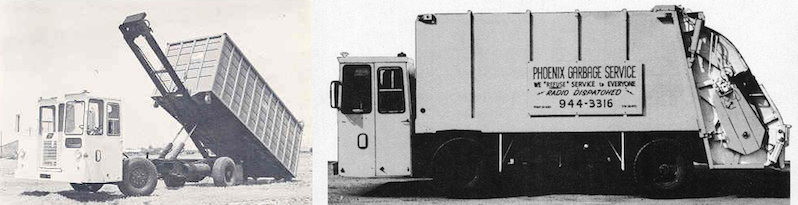

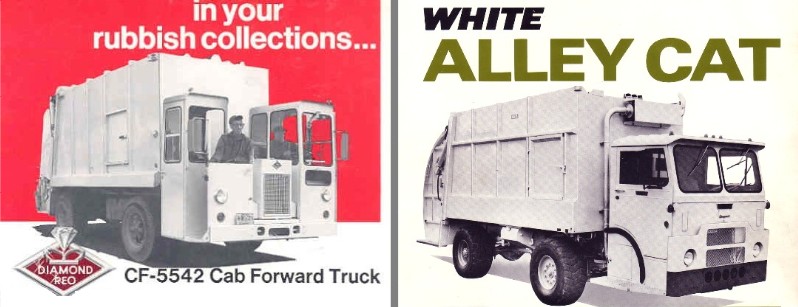

A top-hinged hydraulic-powered rear door was fairly rare on the Jet The Jet front loader was marginally more successful than the Gar Wood T-100, but never saw much use outside of the western states. In 1967, Both Reo Motors and Diamond T Trucks were merged by their owner, the White Motor Truck Company. Thereafter, Wesco Jets remained mostly unchanged but were badged as Diamond Reo, with the new designation CF-5542. White began selling their own version by 1971, known as the "Alley Cat" with a full-width White cab replacing the twin phone booths.

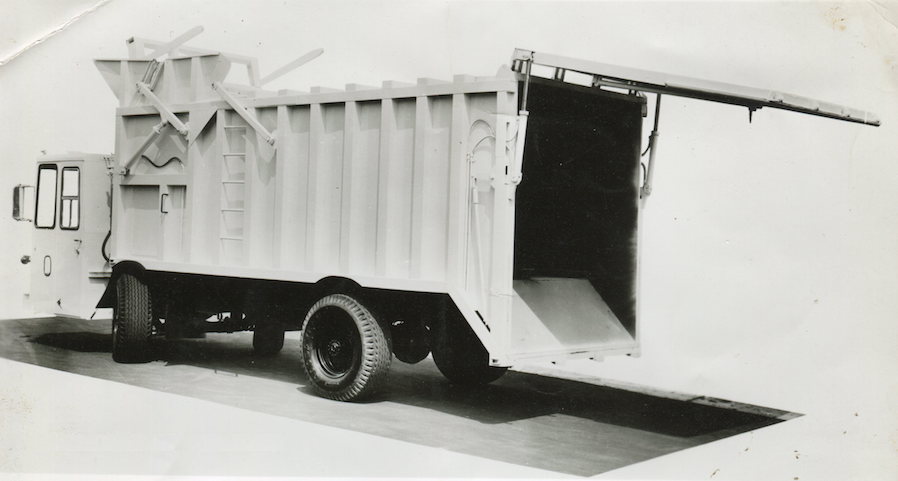

An early Wesco Jet unloads as the helper checks behind the blade

After 1967, Jet chassis were badged as Diamond Reo, model CF-5542 Wesco Jet Truck Chassis

Western Barrel Snatcher

This is probably the original Barrell Snatcher being tested at Western Body & Hoist in 1970 Like every other manufacturer, Western Body & Hoist didn't have anything like what Stragier envisioned, but Morrison did have his Jet, and came up with a concept in which a can-grabber arm (with a 12-foot reach) replaced the front loading arms and forks. The idea became a reality in August, 1970 when a Western Barrel Snatcher arrived in Scottsdale, the first factory-built automated side loader in history. It was one of only a handful ever built, and the two remaining trucks were supplied by Maxon, which purchased Western Body & Hoist that same year. As with any new idea, the truck was fraught with technical problems, which required years of refinement by Scottsdale's mechanics. The City bore the brunt of this development task at its own expense, and paved the way for more route-ready automated side loaders designed by Marc Stragier by the end of the decade.

George Morrison came up with the concept for the Barrel Snatcher, based on his Wesco Jet front loader

Dumping a 300-gallon "alley" container The first Barrel Snatcher, Truck 254 of the City of Scottsdale, has been preserved and is on display at the Solid Waste division yard in Scottsdale. Not only is this a rare example of a vehicle of important historical significance to the waste industry, it is a living testament to George Morrison's genius, and a vehicle he had most likely had worked on personally while it was being custom-built at Western Body & Hoist in the 1960s.

Historic Truck #254 on display in Scottsdale, designed by George Morrison

9/9/18 © 2018 All Rights Reserved Photos from factory brochures/advertisements except as noted Logos shown are the trademarks of respective manufacturers |