HAROLD ALEXANDER'S ROLL-OFF

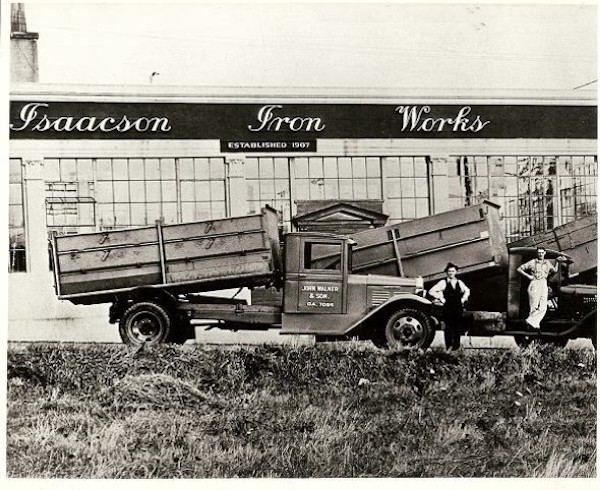

Trucks of John Walker & Sons of Oregon, probably from the 1930s. Open dump trucks remained

popular among small refuse haulers long after the advent of modern packer bodies

It is said that necessity is the mother of invention, and this is certainly true concerning the field of refuse collection equipment. Industrialization, the packaging industry and increasing prosperity in America drove the rapid development of a wide variety of equipment needed to efficiently remove the waste that resulted. The men on the street, refuse haulers and municipal collection agencies, have typically been a big factor in this progression, providing valuable feedback to manufacturers on what works well....and what does not. A few of these men have taken the next step, and created their own designs, from the ground up, to meet their specific job requirements.

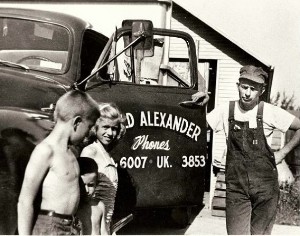

Harold Alexander (1928-2004) entered the hauling business in 1952. Such was the state of refuse equipment at the time, that a great many haulers still relied on antiquated-but-inexpensive open dump trucks for refuse collection, a method dating to the turn of the century. Alexander began his business with a Ford dump truck, serving the West Hills of Portland, Oregon. In a few short years, he would be operating some of the most advanced equipment in the country, much of it of his own design.

Harold Alexander (1928-2004) entered the hauling business in 1952. Such was the state of refuse equipment at the time, that a great many haulers still relied on antiquated-but-inexpensive open dump trucks for refuse collection, a method dating to the turn of the century. Alexander began his business with a Ford dump truck, serving the West Hills of Portland, Oregon. In a few short years, he would be operating some of the most advanced equipment in the country, much of it of his own design.

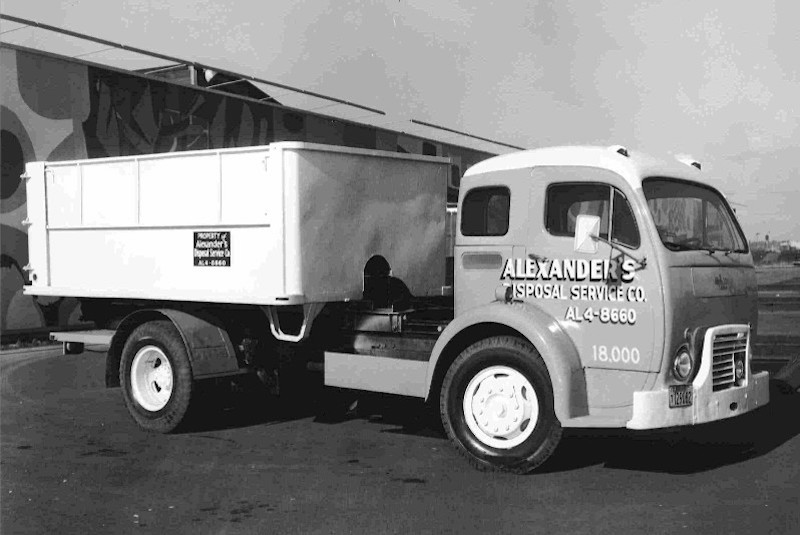

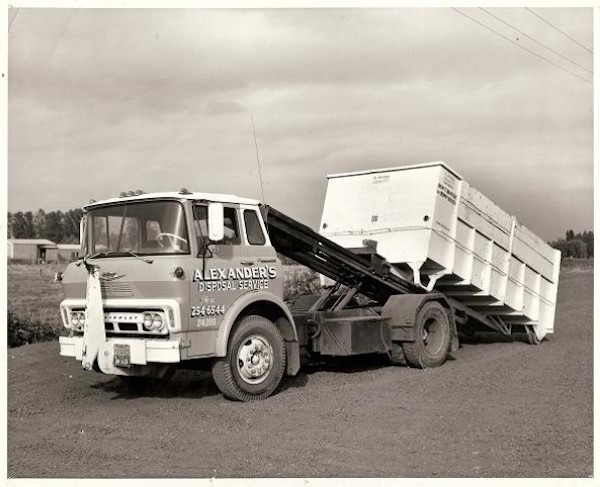

In 1960, Harold Alexander patented a simple and inexpensive system for loading and transporting large stationary refuse containers on a truck chassis. These "roll-off" boxes had much greater capacities than most detachable containers of that time, which typically held only 1-3 cubic yards. Harold Alexander built his first hoist on a 1952 White 3000 cabover chassis.

Alexander's hoist was a cable-and-winch type unit, a hook carried on roller tracks. A key feature was the use of "Box Locks" which automatically secured the back of the container to the boom, eliminating the need for ratchet tie-downs. The entire loading operation could thus be entirely controlled from the cab, without the need for the driver to leave the vehicle. Todd Alexander remembers "Dad's intention was to not market his roll-off, but rather give himself a competitive edge against the other Portland haulers". Alexander built his hoists at a shop on Middlefield Road in Portland, supplying haulers outside of his own area of operation. His design was later sold by Gar Wood Industries, which had an assembly plant in Richmond, California, and was marketed as the Dispos-Haul system.

Harold Alexander also worked briefly with Superior Manufacturing Co. on the roll-off hoist, and created a side container hoist attachment for Superior's existing Super-Pack side loader. The Super-Pack was a mainstay among haulers in the Pacific Northwest until the widespread adoption of automated systems and residential front loaders.

Additionally, Alexander developed a lightweight aluminum carry can, for back-door residential service. Construction of these cans was farmed out to a local 'manufacturer' known as Grand Can. Regarding this company, Todd notes: "Grand Can, which consisted of a older lady whose name I cant recall, she started welding aluminum during World War II, kinda the 'Rosie the Riveter' of the garbage business, don't know if the company is still around or not but every hauler had one."

Superior chain roll-off from the mid-1960s with container-spotting front hook

1960 Chevy with Superior Super-Pack side loader. Note "Grand Can" in storage area under body

In 1973, Harold filed his next patent for a triple-chain roll-off system with hydraulic motor drive and hook-and-roller I-beam. Next, Harold and Todd Alexander, along with John Knapp Jr. collaborated on a redesigned roll-off in 1977 with the I-beam and hook, which was built and marketed by Force Northwest of McMinnville, Oregon. Knapp was also instrumental in the development of the Retriever, a satellite side-loader packer body sold through Peerless Corporation, of Tualatin, Oregon. Peerless was subsequently bought by Heil, which still builds the Retriever.

The advantages of a chain unit include:

-Driver doesn't have to get out of truck to hook box

-Spring-loaded automatic box tie downs

-If equipped with front hook, driver need not off-load box twice when positioning back in same location

-Can push box on to dead-pull trailer with ease

-Can hoist 60,000 pounds

FORCE MAGNUM ROLL-OFF

CLICK IMAGES TO ENLARGE

Force Northwest sold the Magnum chain roll-off for several years, eventually selling out to Peerless in 1988. Peerless, since absorbed into Heil Corporation, no longer makes roll-offs. Versions have also been marketed by General Equipment, AA Welding (Advantage Roll-Off), Cascon Mfg. and Enterprise Sales.

"Harold Alexander's roll-off invention has helped make it easy and efficient for billions or trillions of tons of waste/recycle/scrap metal to be properly handled, contained and safely transported" says Todd Alexander. "It should be considered one of the best contributions to the waste hauling industry, as it has help move more tons than any other system developed!"

Classic Refuse Trucks salutes hauler and inventor Harold Alexander, and sincerely thanks Keith and Todd Alexander for sharing the story of their father and the many great old photographs contained in this article.

See also: Gar Wood Dispos-Haul Roll-Off System here at Classic Refuse Trucks

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US3077278A |

Truck loading assembly with detachable container |

Alexander |

|

December 16, 1960 |

|

US3894644A |

Truck-mounted loader |

Alexander |

|

December 26, 1973 |

8/1/14

© 2011, 2014

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos by Keith Alexander and Zachary Geroux

|

|

| |