ATHEY PRODUCTS COMPANY

Raleigh, North Carolina

By Eric Voytko

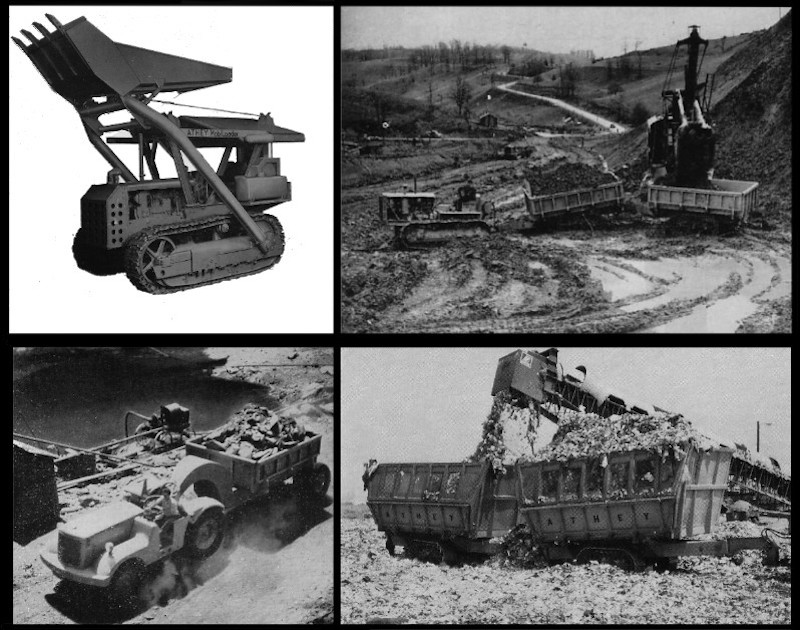

Athey Products began as a manufacturer based in Chicago, Illinois. They specialized in loader attachments and earth-moving equipment such as buckets and trailers. As early as 1937, Athey also built specialized trailers for on-site hauling at large landfills. Athey moved further towards the refuse body industry with the purchase of Mobil Sweeper from American Hoist & Derrick Co. in 1975. Sweeper production was moved from St. Paul, Minnesota to a new plant at Raleigh, North Carolina.

ATHEY REFUSE BODIES

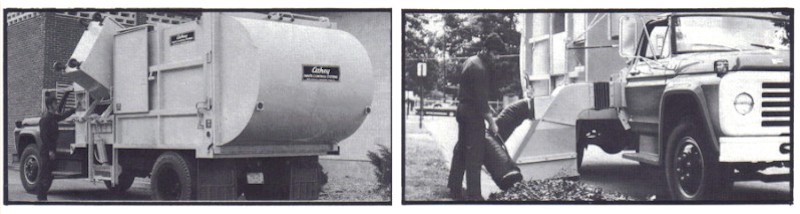

In 1981, the North Carolina plant took over manufacture of the refuse packer product line formerly sold by Cobey Waste Control of Galion, Ohio. This included the old Cobey Fork-Tainer, which became the Athey Tite-Pak front loader. Sizes were still 25, 31 cubic yards, an 35-yard version was created with the addition of a 4-yard bubble tailgate.

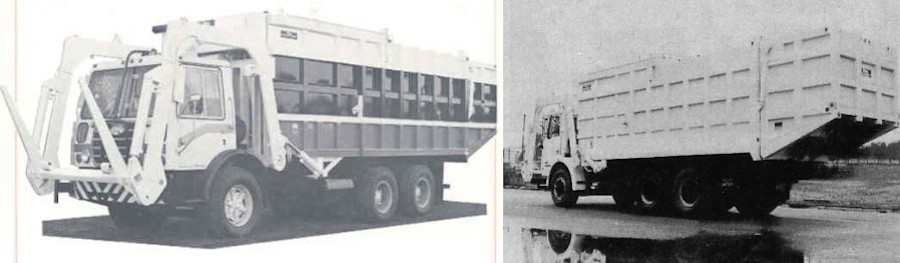

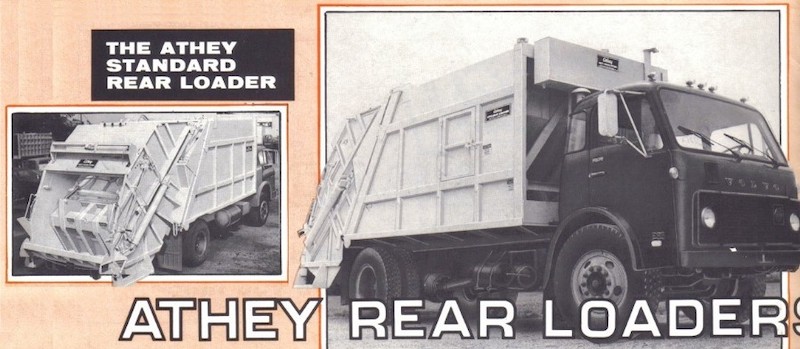

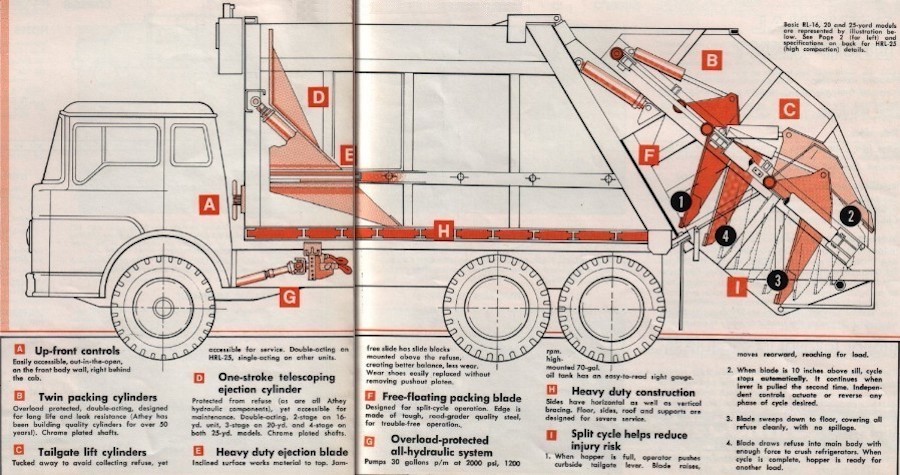

The standard rear loader lineup was continued intact, with 16, 20 and 25 cubic yard models and a semi-trailer version. Flagship of the rear loader line was still the high-compaction model Tite-Pak HRL-25, available only in 25 cubic yard capacity. The options list was also carried over from Cobey, including Transa-Pak pack-on-the go pump, hopper extensions, container lifts, auxiliary engines.

Athey Standard Rear Loader

Athey Standard Rear Loader packing mechanism

Athey Tite-Pak HRL-25 high-compaction rear loader

HRL-25 shows its massive packer blade

ATHEY TITE-PAK SIDE LOADERS

Tite-Pak manual side loaders (MSL) were carried over from Cobey, now advertised as 14, 18 and 24 cubic yard sizes. The three models had not actually increased in size from the Cobey years (10, 14 and 20 yard Helix models), but Athey now added the hopper capacity (4 cubic yards) to the body capacity in their literature. A small, manually operated dumper remained optional to service small containers and steel drums. The leaf & litter vacuum loader attachment was also still available.

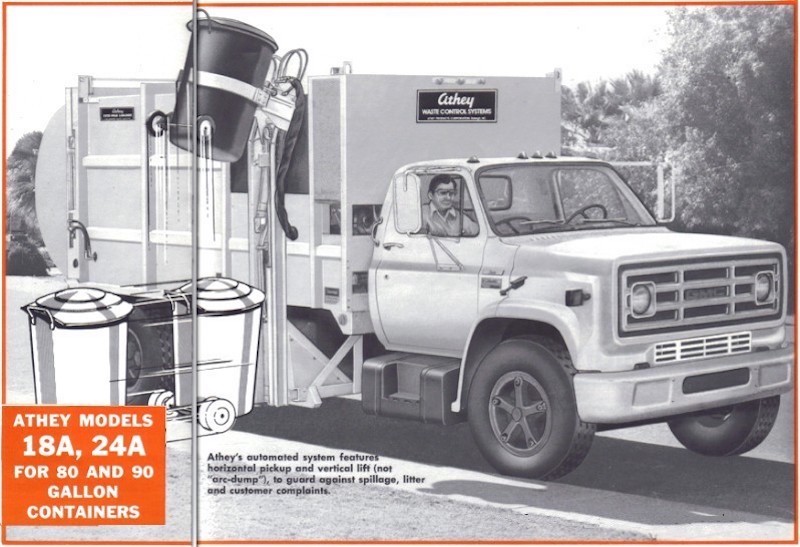

ATHEY AUTOMATED SIDE LOADERS

All-new for Athey was the Tite-Pak CWC 300 (Containerized Waste Collection) automated side loader (ASL), a timely addition to the product line. Athey was among the first to offer a route-ready ASL package to the refuse industry. The heart of the new model was a Litter Lift automated hoist made by Heil Rotomold of Phoenix, Arizona. The hydraulic lift was cab-controlled and had a 2,000 pound lift capacity. Dump cycle time was around 20 seconds, and the operator could speed up or slow down the cycle by feathering the controls.

The CWC 300 was built to automatically lift, dump, and return cross-linked polymer containers of 300, 90 or 80 gallons. The big 300s were typically used as multiple-dwelling residential cans, and had no wheels. The smaller, wheeled cans were for individual households. This system was the fruition of, and direct descendant of automated systems pioneered by the City of Scottsdale, Arizona at the end of the 1960s. By the early 1980s, automation was beginning to spread across the nation as communities sought ways to cut refuse collection costs. The introduction of Athey's new ASL was well-timed to meet that new demand.

The refuse packer portion of the CWC 300 consisted of a beefed-up Tite-Pak side loader body, with an enlarged hopper. The hopper capacity was increased to 5-cubic yards, and the total body capacity was rated at 25 yards. This required a packing cylinder stroke increase from 29 to 43 inches. Blade thickness was increased to 3/16". With the new hopper, continuous-cycling on-the-move, the big unit could service closely-spaced 300-gallon cans without waiting for the packer to 'catch up'. Larger, 3" diameter cylinders were used for the CWC 300 ejector panel. Lighter-duty models 18-A/24-A incorporated the Litter-Lift hoist with standard Tite-Pak side loader bodies. These were limited to only 90/80 gallon containers.

Athey was ultimately a short-term entity in the refuse body industry. The rear loader was the first to be discontinued, sometime in the early 1980s, and the front loader was last advertised in 1985. Only the Tite-Pak manual side-loaders and the CWC 300 ASL remained. The last known ads for Athey refuse bodies appeared in 1986, and later that year, EMCO Manufacturing (Plainview, TX) introduced a new ASL that was nearly-identical to the Athey CWC. It is highly likely that Athey sold or licensed the design of the CWC to EMCO. It lived on as the Challenger by Rand Automated Compaction Systems from 1987 to around 1991. Athey continued with the Mobil Sweeper line until going bankrupt in 2000. The company was purchased by an employee investor group in 2001, which subsequently sold out to Federal Signal Corporation.

SELECTED PATENTS

|

Patent # |

Description |

Inventor |

Assignee |

Date |

|

US4597710 |

Trash collection vehicle side-loading apparatus |

Kovats |

Athey Corp. |

November 28, 1984 |

1/8/12 (revised 12/08/24)

© 2012

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

|

| |