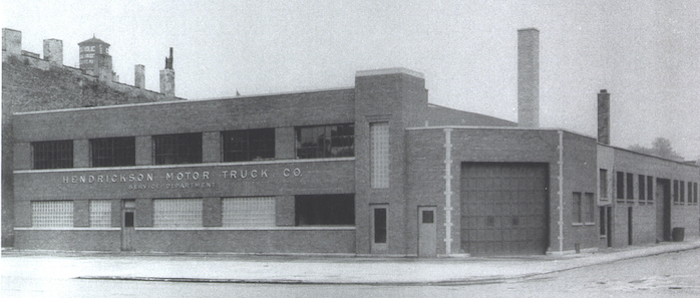

Hendrickson

Lyons, Illinois

Magnus Hendrickson founded the Hendrickson Motor Truck Company in 1913, along with his sons George and Carl, thirteen years after he had built his first truck. Established in Chicago, the company opened a new shop in nearby Lyons , Illinois in 1927 to handle growing orders for their "walking beam" suspension system. Hendrickson was a major supplier of truck suspensions during WWII, all used on International Harvester truck chassis.

After the war, the name was changed to Hendrickson Mfg, with separate divisions for suspensions and motor trucks respectively. Hendrickson suspensions earned a reputation for being the best in the industry, and have found their way on to a wide variety of OEM chassis since that time. The motor truck division increasingly catered to the specialist vehicle and custom truck chassis market. More than a few refuse haulers were customers, particularly in, but certainly not limited to, the Midwest United States.

Early Hendrickson with an open refuse body owned by contractor James Duffy

Magnus Hendrickson and sons pose with a 1936 International using their Walking Beam suspension

Hendrickson dump truck for Chicago's Groot Scavenger

Hendrickson had long-running association with International Harvester, using K-series conventional cabs

as well as the famous CO-series tilt-cab seen here with a this 1950s Roto-Pac body

Hendrickson conventional (IHC cab) with Stratton Hydro-Loader body

Custom chassis and walk-in cab for a Chicago area contractor, powered by a Detroit Diesel 4-53 engine

The body is one of the very first Leach 2-R Packmaster tilt-to-dump bodies

A 1960 Hendrickson using the fiberglass International CO cab and RD-450 engine

Hendrickson custom walk-in with a 25-yard Heil Colectomatic Mark III packer for Groot Disposal

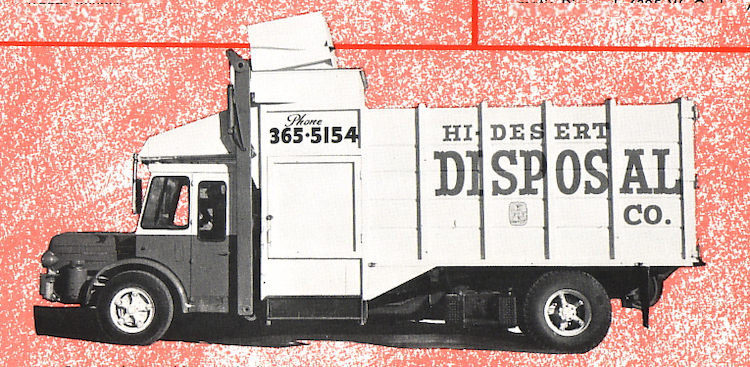

Another unusual walk-in cab using the IHC conventional nose, built for a hauler in Yucca Valley, California.

Body is a Bowles Load-n-Pack side loader fitted with front-loading arms

Hendrickson tilt-cab with a Leach 2-R Pushout body for Dooley Brothers, Roxbury Massachusetts

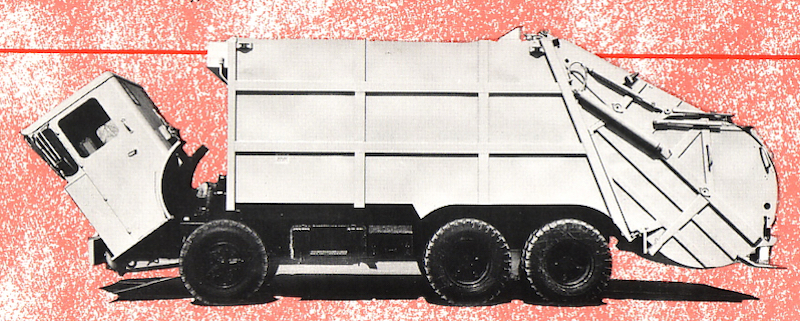

From Tom Styczynski, former Hendrickson engineer: "An interesting 1970 project: a customer wanted to increase the load capacity requiring tandem rear axles. He was concerned that the truck would be difficult to turn into alleys. He promised a purchase of several trucks if we could solve the problem without a significant cost increase and did not want a cab over design noting maintenance issues.

"Mike Signa, Assistant Chief Engineer at Hendrickson, had an idea: We moved the front axle back about twelve inches, then cut the fiberglass front fenders and narrowed the bumper. This provided tire clearance for the relocated front axle and reduced the front swing envelope. The result was crude, but the customer was sold."

"The production design (above), with a better front fender design. He purchased several vehicles for his fleet."

|

10/3/2020

© 2020

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

| |