Helix Corporation

Crown Point, Indiana

This page was originally published in the COBEY album at Classic Refuse Trucks

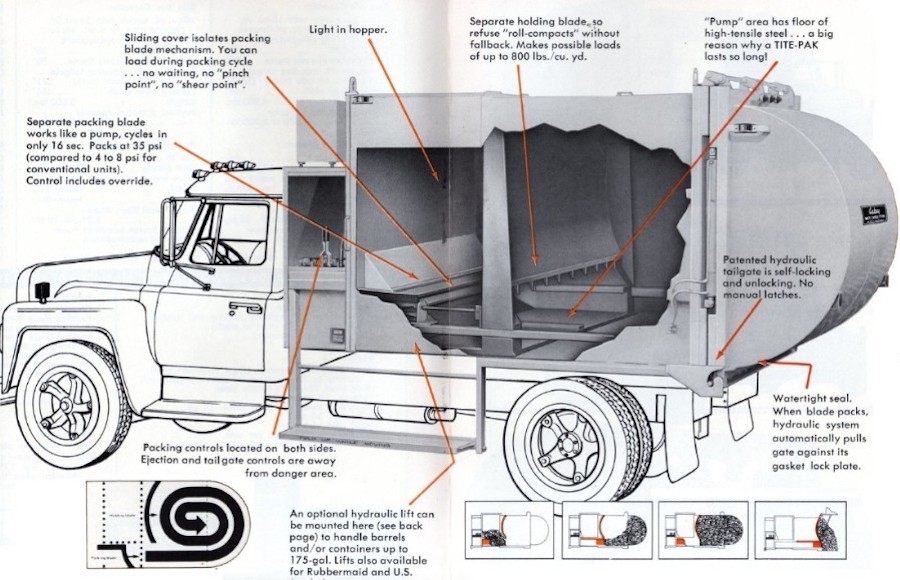

The Helix Company of Crown Point, Indiana began manufacturing the compact Tite-Pack side loader around 1971. This ten yard body featured a unique split-packing panel, with the short lower-portion acting as a plunger to clear the four cubic yard hopper, and the large upper portion serving as a retainer and ejector plate. The bubble tailgate imparted a rolling action to the load, and the shorter blade delivered 35 P.S.I for claimed compaction densities of up to 800 pounds per cubic yard. To eject, the twin blades worked together as one to clear the body.

The Tite-Pack was the creation of Henry W. Churchman of Wichita, Kansas. Churchman died in 1971, and his patent was assigned to Helix Corporation. ostensibly by his widow who retained the rights by inheritance. It is highly likely that Churchman didn't live to see his design come to fruition, but it was to have quite a long production run under several brand names.

The packer blade and ejector blade were made as an assembly, forming a sliding carriage within the body, powered by hydraulic cylinders mounted longitudinally. When this assembly was fully retracted forward, the ejector portion stopped just short of the loading door, forming a bulkhead to define the refuse storage compartment and prevent fall-back. The assembly was fully extended to eject the load out the rear opening of the body.

The lower portion of the blade, which performed the packing, operated just like a conventional drop-frame side loader, such as the Shu-Pak. This short blade moved back and forth the distance of the loading hopper floor, shoving each charge of refuse under the ejector portion. This short packing blade (sometimes referred to as the 'pump' in Cobey brochures) and its two cross-mounted packing rams were completely contained within the sliding assembly mentioned previously. A follower plate allowed for continuous loading of refuse while the packing blade was in motion.

When the body was full, the short blade was extended rearward, which closed-off the opening in the ejector blade portion. Then the whole assembly was extended (by the side cylinders) to eject the load. When larger body sizes were eventually added to the product line, this meant longer overall body length. To overcome the added length, two-stage telescopic ejector cylinders were used on these larger models.

Harsco Corporation, parent company of Cobey, bought Helix in 1973, and it briefly became an independent division of Cobey. By 1974, Helix Corporation was fully merged into the Perfection-Cobey Waste Control Systems Division, and the little side loader had its name shortened to Tite-Pak. Larger 14 and 20 cubic yard body sizes were added that year. A dumper mechanism was optional for emptying wheeled containers or 55-gallon drums, foreshadowing Tite-Pak's future as an automated side loader.

New for 1975 was this Helix fitted with a 51-HP Universal leaf collector. Leaves were discharged by the impeller fan into the screened hopper, then packed in the body. Within minutes, it could be converted back to use as a refuse packer. This attachment added to the versatility of the side loader, and could also be used to vacuum up lightweight refuse.

|

See also: Cobey, Athey

1/8/12

© 2012

All Rights Reserved

Logos shown are the trademarks of respective manufacturers

Photos from factory brochures/trade advertisements except as noted

|

| |