BRITISH REFUSE COLLECTION VEHICLES OF THE 1970s

By Trevor Wood

Originally published in the CRT News Update, July 4, 2010

Can you imagine driving a vehicle in which the steering controls had been moved to the other side of the cab, but not the gear shifter or stop lever? How about a refuse truck that hurls shards of refuse out its front end? Trevor Wood has had just such experiences, and more. What follows is a fascinating (and sometimes hilarious) look back at what it was like, from the dustman's point of view, to use these machines. As many of us have worked in the refuse industry, Trevor's accounts will probably remind us of our own experiences, good in bad, with sometimes-cantankerous refuse equipment.

Trevor starts with Glover, Webb and Liversidge:

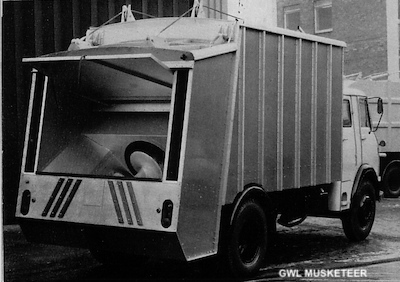

"I worked on these RCV's [Refuse Collection Vehicles] in the early seventies and would like to make a few comments. At our depot we had had a 1966

Musketeer with twin screw, it was hydraulic driven with a forty gallon oil tank bolted on the side of the chassis causing the vehicle to have a permanent list to the offside. The hopper was attached as per the Ramillies. It was actually safer than the later ones, as the screws could be stopped at will or reversed by a hydraulic control on the back. I remember before I worked there, they had a few Loadmasters (or were they Blenheims?) They had a pendulum type compaction action. "

"I worked on these RCV's [Refuse Collection Vehicles] in the early seventies and would like to make a few comments. At our depot we had had a 1966

Musketeer with twin screw, it was hydraulic driven with a forty gallon oil tank bolted on the side of the chassis causing the vehicle to have a permanent list to the offside. The hopper was attached as per the Ramillies. It was actually safer than the later ones, as the screws could be stopped at will or reversed by a hydraulic control on the back. I remember before I worked there, they had a few Loadmasters (or were they Blenheims?) They had a pendulum type compaction action. "

"This brings me on to the Loadmaster 202. We had the prototype for these, it was called the Grenadier and it was pretty hopeless. It was built on a secondhand 1967 Commer chassis which had an awful steering lock and was about 35 feet long. Many corners that a Revopak would make in one sweep required one or more shunts with the Commer. The body was something else! Firstly, mounted on the cab dashboard was an A4 size picture frame complete with glass which housed the operating instructions. These consisted of a red lever and a yellow lever. The mechanism was driven from a gearbox PTO and had an extra propshaft running under the body to the hopper in a similar fashion to later Musketeers. It was not continuous loading; a lever on the side of the hopper had to be pulled down to start the compacting cycle. We did discover that on occasions it would decide to become continuous... but only when it felt like it! This would also happen without notice, which was a bit of a concern! It had a hinged rail the full width of the hopper, which came up when the cycle commenced to prevent loaders getting too close whilst the plate went round, and it caught most of us in the stomach. "

"My most amusing memory of it was that the dust seal on the ejection barrier was about an inch too short, also there was no floor in the body at the front part where the barrier frame sat. This we discovered when we got it three-parts loaded and we saw bits of broken glass, cinders, etc. flying across the road. It was pushing the small bits under the ejection barrier which then fell through on to the revolving PTO shaft and broadcast themselves everywhere! This vehicle was bought for a rural round, which it was hopelessly too big, and then became a spare vehicle. Most crews used it on occasions, and it finally 'died' when in use by a rural crew. Having filled the hopper, the lever was pulled to commence packing, but it decided to go in reverse. There was a big bang and lots of bits of broken and mangled metal. It was returned to GWL to have an improved hopper fitted, but I don't remember it ever returning. Instead they sent us a single-cabbed Musketeer which we found out would, when fully loaded, spring the hopper open: the two hooks that held the hopper closed were worn. On the occasion it happened to us, we were about ten miles from the tip, and we left a trail of broken glass, ashes etc. all the way there."

"My most amusing memory of it was that the dust seal on the ejection barrier was about an inch too short, also there was no floor in the body at the front part where the barrier frame sat. This we discovered when we got it three-parts loaded and we saw bits of broken glass, cinders, etc. flying across the road. It was pushing the small bits under the ejection barrier which then fell through on to the revolving PTO shaft and broadcast themselves everywhere! This vehicle was bought for a rural round, which it was hopelessly too big, and then became a spare vehicle. Most crews used it on occasions, and it finally 'died' when in use by a rural crew. Having filled the hopper, the lever was pulled to commence packing, but it decided to go in reverse. There was a big bang and lots of bits of broken and mangled metal. It was returned to GWL to have an improved hopper fitted, but I don't remember it ever returning. Instead they sent us a single-cabbed Musketeer which we found out would, when fully loaded, spring the hopper open: the two hooks that held the hopper closed were worn. On the occasion it happened to us, we were about ten miles from the tip, and we left a trail of broken glass, ashes etc. all the way there."

|

Trevor continues with stories of Shelvoke & Drewry (SD) and Eagle refuse collection vehicles of the 1970's:

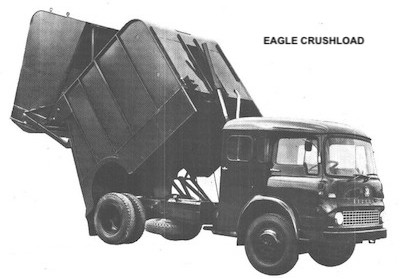

"I worked on the dustcarts from 1972 until about 75, and worked on most of the common makes but always found the SD to be the best. I joined Dorking U.D.C. [Urban District Council] in October, 1972 who at that time had three TZ Pakamatics, one F&A with bulk bin lift and a Bedford TK with Eagle Crushload body."

"The oldest Pakamatic, a 1964 version with bulk bin attachment was quite a thing. When fitted for Paladin bin handling, [manual hand-loading] doors were fitted on the rear, either side of the lifting mechanism. This vehicle was mainly used for manual loading, and it required quite a knack to empty a bin through those holes without getting cauliflower ears from the bin! A fact most of our crews discovered when the vehicle was replaced by a Revopak, and thus became 'the spare.' Because of the extra weight on the rear end, it would easily stand on its back legs when tipping, something I found out when taking a drink in the cab while emptying...it nearly choked me! It also had the habit of breaking half shafts fairly often. Because of the sloping hopper sides on these early versions the driver had to constantly push the refuse in with a shovel because we were loading in the corners of the hopper."

"The oldest Pakamatic, a 1964 version with bulk bin attachment was quite a thing. When fitted for Paladin bin handling, [manual hand-loading] doors were fitted on the rear, either side of the lifting mechanism. This vehicle was mainly used for manual loading, and it required quite a knack to empty a bin through those holes without getting cauliflower ears from the bin! A fact most of our crews discovered when the vehicle was replaced by a Revopak, and thus became 'the spare.' Because of the extra weight on the rear end, it would easily stand on its back legs when tipping, something I found out when taking a drink in the cab while emptying...it nearly choked me! It also had the habit of breaking half shafts fairly often. Because of the sloping hopper sides on these early versions the driver had to constantly push the refuse in with a shovel because we were loading in the corners of the hopper."

"The Revopak which replaced it was like a Rolls-Royce. Even though we still loaded through the doors either side of the slimmer rack & pinion bin lift, we could not block it up no matter how quickly we loaded. The door to gain access to the ejection barrier was also useful as an emergency toilet, no doubt Health & Safety would not approve! On one occasion, I was operating the bin lift when a wheel came off the raised Paladin bin and hit me on the head - no hard hats then - I saw stars for a while then carried on working."

"The Eagle Crushload was a strange beast, funny thing was we always noticed the smell of the load more with that than with the Pakas. It had electro-hydraulic switching for the compacting mechanism and would blow the fuse, which was situated in the cab, if it jammed up.  The 'fuse' of course was a bit of silver paper or small nail, whatever could be found to keep it going. To empty the Crushload involved undoing a valve behind the cab and pumping a handle until it went solid, this diverted the oil to the tipping rams. Once empty the valve was switched back and the handle pumped again. On one occasion we forgot this and when the driver switched on the system as we travelled to site the body came up. Fortunately there were no bridges in the area." The 'fuse' of course was a bit of silver paper or small nail, whatever could be found to keep it going. To empty the Crushload involved undoing a valve behind the cab and pumping a handle until it went solid, this diverted the oil to the tipping rams. Once empty the valve was switched back and the handle pumped again. On one occasion we forgot this and when the driver switched on the system as we travelled to site the body came up. Fortunately there were no bridges in the area."

"In April 1974, amalgamations took place between Dorking U.D.C., Leatherhead U.D.C. and the rural part of Dorking & Horley R.D.C. to form Mole Valley District Council. It seems unbelievable that up to this time Gatwick airport was in Surrey and came under Dorking & Horley Rural District Council! This is where the Glover, Webb & Liversidge (GWL) vehicles came from, plus a fifteen cubic yard SD F&A and a 35 cubic yard SD F&A - the big one with the pneumatic operated rear door. From Leatherhead came one SD F&A, several Dennis Paxits and a couple of Bulkmasters."

"I worked on one of the rural Musketeers for about a year. It was one of two that were cancelled export orders, and were built as left-hand drive and then converted to right-hand drive. This conversion was basic, the engine stop was under the passenger seat, the gear change was nearer the passenger than the driver and it took a lot of getting used to. This was on the usual Commer/Karrier chassis and the cabs were a real problem. These rural rounds were crewed by just two men, and involved a lot of getting in and out of the cab. We had the door strikers adjusted several times but they still gave trouble. On one occasion we were travelling over a narrow bridge on a sharp bend when the passenger door flew open and I was on my way out of the cab, fortunately my driver, a huge chap managed to grab hold of me. We decided that the only way to get these doors fixed was a bit of 'direct action'. Later that day we had to travel down a narrow unmade track which had a large tree along it's verge. As we approached the tree, I put my foot against the door, undid it and gave a good bootful to it. It hit the tree OK as planned but swung back, flew forward again and dislodged the householder's gatepost. We apologised to him of course, and explained we kept having trouble with these doors. He was OK with that, put in a claim, and of course we got our doors fixed properly."

"My interest has always been in the different types of vehicles but I particularly liked the Fore & Aft tippers. From the dustman's point of view, you could get almost anything in the back [which] equals more tips! "

|

Many thanks to Trevor Wood and Brian Carpenter for sharing these great stories with CRT

7/4/10

© 2010 Trevor Wood

All Rights Reserved

Photos from factory brochures/advertisements except as noted

Logos shown are the trademarks of respective manufacturers

|

|